This file type includes high-resolution graphics and schematics when applicable.

For IoT device fleets, there are many misconceptions about data analytics and its relation to business results. Here are 11 myths to consider.

1. Quantitative analysis is better than human intuition.

Data analytics and analysis often promote the idea that quantitative, fact-based understanding is better than human intuition. Although it’s true that human bias can distract us at times, three fundamental aspects of data analysis for IoT require human intuition:

1. Pinpointing the business and user questions that need to be answered.

2. Identifying the data needed to support the answers to those questions.

3. Instrumenting the system to gather the right type and amount of that data.

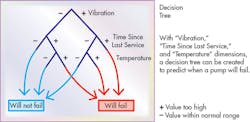

For example, to find out when a pump might fail, a data scientist could gather a multitude of data and look for an answer in the noise. However, a more efficient approach would be to identify what questions need answering (e.g., “How can we know when a pump is about to fail?”), identify what data is needed to support the answers (e.g., talk to the pump designer to identify that vibration and pressure are key to understanding failure modes), and then instrument the pump to find the right type of data (e.g., add vibration and pressure sensors that sample at an appropriate rate).

The necessary data can only be captured after capturing and implementing these human intuitions, which would then allow a data scientist to refine the predictive model needed to identify when a pump is about to fail. Figure 1 shows how simple pump vibration, temperature, and service intervals can be used to classify the difference between a projected pump-failure condition and normal operation.

2. Everyone is ahead of you in terms of adopting data analytics for IoT device fleets.

Data analytics for IoT device fleets is still in the early stages of industry maturity. Few organizations have mature data-analytics programs in place to support their IoT data, and there’s no magic bullet—the type of analytics that help one solution succeed are irrelevant for other solutions. As a result, organizations still have a significant opportunity for competitive differentiation by understanding and deploying pragmatic data-analytics solutions. To succeed, companies need to push aside the current hype of analytics and exploit these pragmatic solutions. For example:

• Local analytics at the sensor or device level that down-sample high-frequency sensor readings and send summarized data up to the cloud reduces latency, bandwidth, and cloud storage costs

• Stream analytics that transform data or look for patterns or trends in data streams that indicate areas of concern can solve many types of data analytics problems. These include machine health-indicator problems, predictive maintenance problems, and service delivery problems

• Big-data analytics that process and analyze large amounts of data to find trends occurring within a family of devices or in combination with manufacturing or point-of-sale information.

As data analytics for IoT continues to mature, forward-thinking, pragmatic companies that deploy analytics in a way that solves real-world problems will move ahead.

3. Every problem is a data-analytics problem.

IoT deployments can solve many types of problems, most of which aren’t data-analytics problems. For example, a dialysis machine that includes a water-filtration system could be Internet-enabled by an enterprising company looking to deploy data analytics to the problem. By adding numerous sensors to the machine, they may hope to arm a data scientist with the information necessary to calculate machine health and failure mode diagnostics.

However, one of the most obvious health indicators to measure in a dialysis machine is the pressure drop across the water filter. If it’s higher than a certain threshold, it’s time to change the filter. Simple—no need for complex data analytics.

For many IoT solutions, bringing the full complement of data-analytics tools, services, and resources to the problem can at times overcomplicate the solution, increasing the cost and decreasing the effectiveness. Not all problems are data-analytics problems.

4. Everything is new or everything is old.

In the hype of data analytics for IoT, we often hear one of two fallacies: Everything is new, or nothing is new. Rather, the truth is a mix of the two. Data-analytics fundamentals are grounded in probability and statistics. However, data analytics is combined and deployed in new ways with IoT:

• IoT solution complexity: IoT deployment topologies are complex and require chains of data-analytics pieces that combine together to create a whole solution. For example, sensors connect to devices that can be controlled by smartphones. Gateways send aggregated device data over cellular networks to cloud platforms. In the cloud, the data streams are analyzed before resting in production database clusters and/or a data warehouse, where further analytics are applied to derive insights on a fleet. This chain of analytics creates a new set of rich problems for us to solve.

• IoT solution depth: Because IoT solutions are often systems of systems (e.g., a pump inside a subsystem that’s inside a machine embedded in a process, which is monitored and controlled remotely), the number of possible analytics dimensions and the depth of the analysis required can be intense. To successfully monitor a system and predict failure requires an in-depth understanding of the full system.

5. Data scientists are readily available.

The McKinsey Global Institute predicts that by 2018, the United States will experience a shortage of 190,000 data scientists. This means that just as companies need data scientists to fulfill their IoT data-analytics visions, there will be a shortage of resources. Although the number of data-science consulting firms and practices is on the rise, companies that put off developing internal skills and competencies in the area of data science will find themselves left behind when it matters most.

6. The search for data-analytics insights can be automated.

Lost in the hype of data analytics is the fundamental truth that true business insights can’t be found through automated means alone. Data analytics not only cooperates with human intuition, it also depends on it. For example, understanding what can cause a hydraulic elevator to fail comes with years of experience designing and repairing elevators.

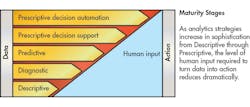

The insight that informs IoT solution designers about what to measure to answer unknown questions (e.g., “How do we automatically determine when an elevator is 60% likely to fail within 90 days?”) requires human intuition. Only after those hypotheses are developed can data analytics be applied to real elevator data to prove or disprove the hypotheses. This combination of human input and automation creates meaningful business results. Figure 2 shows a model for data-analytics maturity that illustrates the cooperative relationship between different types of data analytics and human intuition.

7. Machine learning is what you need.

Machine learning is a promising new field with academic roots in pattern recognition and computational learning theory (the idea that computers can have an artificial intelligence allowing them to learn without requiring constant reprogramming). However, machine learning overlaps significantly with the fundamentals of data mining. In most data-analytics problems for IoT device fleets, simple data mining can describe data sets, find patterns, and deploy resulting filters that trigger events upon the appearance of those patterns.

Machine learning is exciting, but organizations can be tempted to take it on too soon, overcomplicating the situation unnecessarily. Use the most basic techniques until it’s clear that the more complex nature of machine learning is needed to answer data-analytics questions.

8. You must have a mathematical background to do analytics.

This is categorically untrue. An increasing number of available resources teach the fundamentals of data science. It doesn’t require calculus or advanced differential equations. For example, Google Analytics Academy, General Assembly’s Data Analysis courses, and the Open Source Data Science Masters are all good places to start.

9. Data analytics for IoT is an IT responsibility.

Data analytics is not just an IT responsibility; it’s a shared responsibility. The nature of IoT device-fleet design combines product engineering, manufacturing, support, sales, marketing, and IT into a cross-functional effort. Portions of data analytics are shared across organizational boundaries and deployed across traditional technology categories. Although IT can and should play a more central role in operational technology (production IoT platforms) and integration in the enterprise going forward, it will yield limited results if done alone.

10. Data analytics is only for large organizations.

Big data has been positioned as a way for large organizations to deal with their mountains of data, which will become more enormous in the future. However, a company of any size can implement pragmatic data analytics. The key is to focus on answering core questions about the product, user, or business processes with sensors and data. Doing that doesn’t necessary require Hadoop or a massive data lake to swim in. Keep the focus on the goal, which in many cases is closer and more achievable than first thought.

11. All data is good data.

Data without context is meaningless. Collecting data without a plan or strategy about how to use it is a recipe for cost, complexity, and unmet expectations. For instance, when monitoring an elevator for failure, it’s possible to collect myriad data like environmental data, light, and acoustic data in the elevator car, travel time between floors, passenger load, and many other metrics that may not make any difference in predicting elevator failure. However, the accurate placement of pressure, temperature and vibration sensors on the hydraulic pump, combined with magnetic switches to monitor car movement, may be all that’s needed to predict problems with reasonable foresight and accuracy.

All data is not good data. The key is to rely on human intuition to develop strong hypotheses that can be proven right or wrong through the deployment of a connected IoT monitoring solution.

Looking for parts? Go to SourceESB.

About the Author

Mark Benson

Chief Technology Officer

Mark Benson, Chief Technology Officer, navigates emerging Internet of Things developments and leads Exosite’s technology strategy to fuel its industry leadership and growth. Benson authored the book, “The Art of Software Thermal Management for Embedded Systems,” and several technical papers and articles, and he is a regular speaker at industry conferences.