Provisioning Reliable Wireless Connectivity for Wearables

This file type includes high-resolution graphics and schematics when applicable.

As the market for trendy smartphones heads toward maturity, the next consumer “must have” appears to be a wearable device. Often designed for use with a smartphone, using its short and long-range gateway connectivity capabilities to cloud-based applications, the demand for wearables is forecast to intensify rapidly.

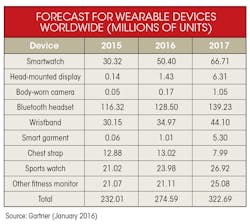

The term wearable is a broad classification that comprises smartwatches, Bluetooth headsets, wristbands, chest straps, sports watches, smart garments, and head-mounted displays like those used for gaming. According to a recent report from Gartner,1 274.6 million wearable devices will be sold in 2016, an 18.4% increase from 2015. They will generate revenue of $28.7 billion, of which $11.5 billion will be from smartwatches.

Among the 274.6 million devices expected to be sold in 2016, the largest unit sales are forecast as Bluetooth headsets (128.5 million), smartwatches (50.4 million) and wristbands (35 million) (see table). While Apple set the smartwatch benchmark with the launch of its Apple Watch, increasingly strong growth is evident with fitness wearables such as sports watches, fitness bands, and vital-signs monitors used by runners, cyclists, and water-sports enthusiasts. According to Gartner, this particular category is set to maintain its average retail price over the next few years thanks to their special application-specific user interfaces, the need for environmental durability, and the continued advances of sensors and analytics.

Keen to offer a broader set of functionality that competes with those of a smartphone, such as mobile payments, wristband manufacturers are working hard to take market share away from the smartwatch sector. These manufacturers also want to develop the premium paid-for cloud-based services that analyze the data generated by the device.

Another application of the fitness-band and chest-strap sectors involves devices used by wellness programs. Initially driven by health initiatives established in the United States, the positive link between an individual’s activity levels and general health continues to gain popularity with health professionals around the world. Many of these programs pay the individual for maintaining a regular exercise regime as opposed to the future high costs of providing health care resulting from lack of exercise.

Connectivity Options

One key requirement for any wearable device is connectivity. Popular methods include Wi-Fi, Bluetooth, ZigBee, and cellular, each having their merits. When faced with developing, for example, a new fitness band, the engineer needs to think about how much data will need to be transferred, how frequently, and over what range it would typically need to be sent.

For nearly every application, there will be a trade off between range, data rate, and use case to be considered. Use-case questions such as “Will the fitness band communicate to a smartphone that then collects data and forwards it to the cloud?” and “Will the smartphone application perform local analysis of the data or will that be done in the cloud?” all have an impact.

Wearable devices will always be battery-powered, which ultimately influences the choice of connectivity method. Bluetooth Low Energy (BLE) is designed for low-power requirements, and is ideal for sending relatively small amounts of data. Virtually any smartphone can support this method of communication.

However, if a higher quantity of data, say a few megabytes needs to be transmitted, then the designer might best consider using Bluetooth Classic or Wi-Fi. After that, range needs to be taken into account. BLE can typically communicate over 30 meters in line of sight.

For the fitness-band example, it’s assumed that the wearer will also have his or her smartphone with them, so distance is not an issue. However, some wearable applications will dictate the use of cellular communication, since they will need independence and reliance on other communication methods. An example might be the use of tracking bands used for workers in isolated locations, so called lone-workers. Other types include child and pet trackers that give locational data in near real time.

1. The SARA-U2 module developed by u-blox measures16 Ã 26 Ã 3 mm and weighs under 3 g, suiting it for space-constrained wearable designs.

One module that provides cellular connectivity is the SARA-U2 from u-blox (Fig. 1). This miniature LGA-sized package (16 × 26 × 3 mm) weighs under 3 g, suiting it for space-constrained wearable designs. It offers high speed 5.76-Mb/s (HSUPA) and 7.2-Mb/s HSDPA cellular data rates, and features low idle mode current consumption down to 0.9 mA.

Ability to Locate

In addition to connectivity, many wearable devices also need to track and record the wearer’s location. Sports-performance monitors and cycling watches use this to overlay the wearer’s heart rate to the actual latitude, longitude, and elevation.

Incorporating positional capabilities into the design can be achieved in one of two ways. The most obvious is through the use of a Global Navigation Satellite System (GNSS) receiver that naturally, for any wearable application, needs to be the smallest and most power-efficient possible.

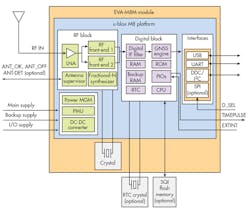

The EVA-M8M (Fig. 2) is an example of a GNSS module. The 43-pin, LGA-packaged device measures 7 x 7 x 1.1 mm, weighs 0.13 g, and consumes up to 25 mA in full continuous operation, but down to as low as 5.5 mA in the power-save mode, where the GNSS data is updated every second.

Like any GNSS system achieving a reliable position “fix,” it relies on the antenna being able to “see” the satellite. Achieving this indoors or where the satellite signals have been reflected by large buildings, such as in dense city centers or in any area of marginal signal conditions, represents a major challenge.

Some wearable devices might need reliable indoor reception more than others, such as aforementioned lone-worker application. Should this be a design requirement, and the primary communications method is through cellular means, then a mobile-network-based positioning approach can complement the GNSS data. By maintaining a database of the positions of cellular network towers, a cellular service, such u-blox’s CellLocate (Fig. 3) can estimate the location of the device based on previous observations from other CellLocate-enabled modules.

3. Mobile-network positioning technology like CellLocate can estimate the location of a device based on previous observations from other CellLocate-enabled modules.

Pre-Development Considerations

When trying to meet a wearable design challenge, what key steps must an engineer review before commencing development? One early step is a thorough understanding of the device requirements. Questions to ask include: “What will the wearable application monitor?”; “What sensors need to be incorporated?”; and “What are the potential use cases?”

Reviewing use cases is a crucial aspect, since it will highlight key factors such as product size, available space envelope, and duty-cycle expectations. These will shape the space available for a battery and have an impact on battery capacity, which of course directly correlates to the time between charge cycles and operational duty cycle.

The various use-case scenarios will also identify the type of communications required. Does it need to use a smartphone as a gateway to a cloud application, or will it communicate directly using its own cellular data connection?

An increasingly important consideration for many Internet of Things (IoT) devices is that their firmware be updated over the air (OTA). This would eliminate the user having to download new device images to a PC from the manufacturer’s site and upload to the wearable device. The specification of the host processor and the amount of memory needed to achieve OTA might need careful review should this be the case.

Most wearable devices will most likely experience the same environmental influences as the wearer. Rain, moisture, dust, and wide temperature variances all need to be taken considered for the product enclosure’s design. Will it require an ingress-protection (IP) rating to satisfy the marketing specification while balancing these factors with the experience for the user?

Ending up with a wearable device that the user finds uncomfortable to wear due to its size, weight, and shape are all critical factors for future success of the product. The engineer needs to look not only at the electrical specifications of the components selected, but also their physical attributes. As noted earlier, the SARA-U2 cellular module and the EVA-M8M GNSS module together weigh just 3.13 grams, making their combination suitable for any wearable design.

Gauging BOM Via Analysis

The marketing requirements analysis of any product will also estimate potential volumes. These will shape a number of production decisions and greatly influence the overall BOM goal.

From the connectivity standpoint, this might prompt many engineers to review whether a discrete design is better than using a module. The difference of cost against price is a hard-learned lesson. The BOM for a discrete approach might be slightly cheaper, but when factoring in the test and certification costs, the difference becomes nominal if anything. When it’s not known where a device might be sold, using modules that are pre-certified to most worldwide wireless regulatory bodies can be a huge timesaver in PCB design.

Also, RF design is a specialist skill and requires equally specialist test equipment and facilities. Having to spend many weeks addressing EMI problems resulting from a poor track layout (and facing a potential PCB redesign) would negate all of the cost benefits of a discrete design.

Power-Saving Mindset

Making the available power budget last as long as possible is a skill that many embedded engineers know through trial and error. When selecting connectivity and GNSS modules for a wearable design, engineers need to carefully review the module’s technical documentation. They must pinpoint the methods that can both keep power consumption to a minimum while not affecting the device’s responsiveness, particularly when it comes to user interaction.

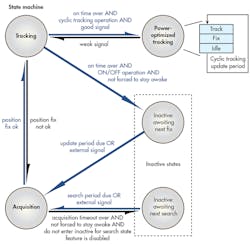

4. As shown in this state diagram, the EVA-M8M uses a power-save mode to reduce system power consumption by turning parts of the GNSS receiver on and off.

Most microcontrollers and modules available today will offer several different power-saving modes; engineers need to diligently review these to find the scheme best suited to the application’s needs. Typically, such modes will selectively turn parts of the module’s functions on or off. For example, the u-blox EVA-M8M uses a power-save mode to reduce system power consumption by turning parts of the GNSS receiver on and off (Fig. 4).

The power-saving mode is based around five different states defined as inactive (awaiting next fix and next search), acquisition, tracking, and power-optimized tracking. The power-consumption profiles differ with each state, with the acquisition consuming most power down to inactive, where most parts of the receiver are switched off. Taking full advantage of these power-saving modes in the GNSS module and similar methods available within the connectivity module will considerably enhance the wearable device’s battery life and, in turn, the user experience.

Paul Gough is Principal Corporate Strategy for u-blox.

Reference:

1. Gartner–Forecast: Wearable Electronic Devices–Worldwide–2016, News.