This file type includes high resolution graphics and schematics when applicable.

Editor's Note: Due to the comments at the end of this article, the author has agreed to change the circuit slightly to reflect three AA batteries in series (which agrees with the photo of the battery holder in Figure 1). This will alleviate the problem of placing batteries in parallel in the circuit. As for different chemistries, it was not the intent of the author to encourage the use of different battery chemistries in the same circuit. The common sense approach for any battery-operated product is to use the same chemistry and even the same brand of batteries when multiple batteries are needed to power a product.

Cell-phone batteries often die at very inconvenient times, with no ac power outlet nearby. This adapter design uses three standard AA batteries, which can be bought almost anywhere, to recharge cell phones and other portable devices like music players, e-book readers, and cameras.

The circuit chargers that typically come with cell phones and other portable devices charge the battery for a brief period of time. Then, they stop, check the voltage, and verify the temperature against an internal table before deciding to stop or continue the charging process. The charging regulation required by the battery is performed within the device getting charged, and this design takes advantage of that circuit.

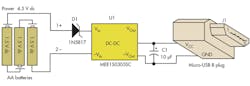

The easier approach to build this portable battery charger uses an integrated dc-dc converter, also known as a point-of-load (POL) regulator. Several units on the market can work here, such as the ISF0305A from XP Power and the MEE1S0305SC from Murata Power Solutions.

The battery holder is a standard 3-cell unit (Fig. 1). The AA size was chosen since it fits easily in a pocket (here, the 12BH331-GR from Eagle Plastic Devices). Larger batteries and holders are also viable for this circuit, as long as the output voltage does not exceed the maximum input voltage of the dc-dc converter. Each AA battery produces 1.5 V. By wiring three cells in series in the holder, it delivers 4.5 V. The POL increases this to 5 V, which is sufficient to charge the battery in the device.

A connector has to be added to complete the design. The type of connector will depend on the device to be charged. Cell phones from Samsung and many other companies require the Micro-USB “type B” receptacle connector (Fig. 2a, Table 1). Meanwhile, Apple uses a proprietary 30-pin dock connector for its iPads, iPods, and most iPhone units. (Apple switched to a “Lightning” eight-pin connector the iPhone 5.) There are multiple connector vendors for the Micro-USB receptacle. We used the 10104109-0001LF from FCI Electronics.

You can cut an available charging cable to avoid the difficulty of getting the right connector. Cutting the cable also makes it easier to check for the wire colors: red (+5 V dc) and black (GND). For Apple units, the best option is to use a “type A” receptacle in this design and then use the proprietary cable to connect to the charger. FCI offers the 87520-0010BLF, but there are many other makers for this popular USB “type A” receptacle connector (Fig. 2b).

The charging circuit can be assembled with discrete lead wires (Fig. 3). It has a bill of materials (BOM) cost of about $5. Diode D1 provides protection against reverse polarization, in case the batteries are inserted incorrectly in the holder.

There are many different standard AA batteries (Table 2). In the 3-unit AA battery holder, the batteries are connected in in series to produce 4.5 V for the regulator. Note that lithium-ion batteries don’t need to be in series. They can all be in parallel. Table 3 reviews some available cell phones along with their battery capacity. Do NOT mix battery chemistries!

This design will provide current on demand to the circuit charger of your end device. The charging time depends on the type of batteries used and the target device to be charged. The right combination of AA batteries will provide more energy to the target device to fully charge it. A higher-current device such as the third-generation iPad will need larger batteries (C or D size) to provide enough current for the portable target, which can be accommodated by changing the battery holder.

Although a POL is a quick approach, it has low charging speed due to the limited current it can supply (200 mA maximum). A fully discharged battery will take more current, and the charging current drops when it is fully charged.

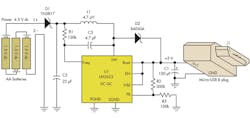

An alternative is to design your own dc-dc converter using a boost approach and IC such as the LM2623, a step-up converter capable of providing 5 V at 1 A from the batteries, with a BOM under a dollar (Fig. 4). Again, the end device will take only the current required to charge itself.

This file type includes high resolution graphics and schematics when applicable.

About the Author

David Bonyuet

Contributing Editor

David Bonyuet has been a passionate electronic gadgeteer and white hat hacker for more than 30 years. He graduated with a BSc in electronic engineering, obtained a PhD in telecommunication engineering from the Technical University of Catalonia (UPC, currently referred to as BarcelonaTech), and did the Entrepreneurship Development Program from the Massachusetts Institute of Technology (MIT). He has developed products for industrial, aerospace, medical, and robotic applications. He always strived for robust systems for the most stringent regulatory standards.