Download this article in .PDF format

A supercapacitor is a double-layer capacitor that has very high capacitance but low voltage limits. Supercapacitors store more energy than electrolytic capacitors and they are rated in farads (F). Supercapacitors store electrical energy at an electrode–electrolyte interface. They consist of two metal plates, which only are coated with a porous material known as activated carbon. As a result, they have a bigger area for storing much more charge.

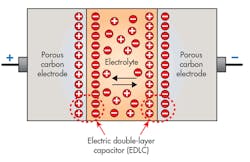

The plates are immersed in an electrolyte made of positive and negative ions dissolved in a solvent. When a voltage is applied, two separate charged layers are produced on the surface with a small separation distance. This is why supercapacitors are often referred to as electric double-layer capacitors or EDLCs (Fig. 1).

Supercapacitors have many advantages. For instance, they maintain a long cycle lifetime—they can be cycled hundreds of thousands times with minimal change in performance. A supercapacitor’s lifetime spans 10 to 20 years, and the capacity might reduce from 100% to 80% after 10 or so years. Thanks to their low equivalent series resistance (ESR), supercapacitors provide high power density and high load currents to achieve almost instant charge in seconds. Temperature performance is also strong, delivering energy in temperatures as low as –40°C.

On the other hand, supercapacitors are offset by their low energy density. Thus, they can’t be used as a continuous power source. One cell has a typical voltage of 2.7 V; if higher voltage is needed, the cells must be connected in series.

Supercapacitors are used in many power-management applications requiring many rapid charge/discharge cycles for short-term power needs. Some of these applications include:

• Voltage stabilization in start/stop systems

• Electronic door locks in the event of power failures

• Regenerative braking systems

• Distribution microgrid

• Medical devices

• Energy harvesting

• Consumer electronics

• Kitchen appliances

• Real-time clock backup

• Utility meters

• Backup power

• Grid stability

• Wind energy

• Energy efficiency and frequency regulation

• Remote power for sensors, LEDs, switches

• Memory-backup SRAM

• Burst-mode power delivery

• Forklift hybridization

For a rundown of standards related to supercapacitors, see “Supercapacitor Standards and Standardized Test” at the end of the article.

Supercapacitor Materials

Different materials, such as various carbon materials, mixed-metal oxides, and conducting polymers, have been used for supercapacitor electrodes. Advances in carbon-based materials, namely graphene, increase the energy density to nearly the level of batteries.

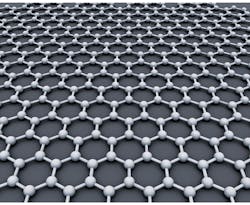

Graphene is a thin layer of pure carbon in the form of a two-dimensional, atomic-scale, honeycomb lattice. Graphene is very strong and thin, with high capacitance value due to its high internal surface area (Fig. 2). Researchers at companies developing commercial solutions for graphene supercapacitors are targeting much more efficient and eco-friendly energy-storage solutions at lower price points. Some technologies have already arrived, some are about to launch, while others are still in the making. Among the latest developments:

Skeleton Technology’s graphene supercapacitors will be key players in a new transport fleet trial in the UK, turning rigid diesel trucks into hybrids through power from regenerative braking for the first time. The hybrid truck system developed by Adgero and Skeleton Technologies, named UltraBoost, will be installed and go through trials on UK delivery routes in coming weeks. During braking, the unit becomes a generator, recovering kinetic energy that would otherwise be lost as heat. At the heart of this technology is a bank of five high-power graphene-based supercapacitors known as SkelMod.

Zap&Go, a UK-based startup, is launching a new type of charger specifically for the business traveler. It uses graphene supercapacitors to charge phones in five minutes. The company had to develop a new type of power supply, because getting enough power into the charger in a few minutes wouldn’t work with existing power supplies. The Zap&Go five-minute charger will be available in the market soon and can be pre-ordered (Fig. 3).

Other companies are developing supercapacitors with interesting applications, too.

Eaton, a power-management company, offers supercapacitor solutions such as coin cells, large cells, small cylindrical cells, and modules. For example, its XLR 48V Supercapacitor Module (Fig. 4) provides energy storage for high-power, frequent-charge/discharge systems in hybrid or electric vehicles, public transportation, material handling, heavy equipment, and marine systems. It doesn’t require monitoring, since the module has built-in cell balancing.

Maxwell Technologies’ supercapacitors are used for regenerative-braking energy storage in the Beijing subway system. China Railway Rolling Stock Corp. (CRRC-SRI) leverages Maxwell’s 48-V modules (Fig. 5) in two sets of regenerative-braking energy-storage devices for the system’s No. 8 line, an urban rail network that runs north-south through China’s capital.

Vishay offers its 220 EDLC ENYCAP with a rated voltage of 2.7 V. It can be used in several applications, including power backup, burst power support, storage devices for energy harvesting, micro UPS power sources, and energy recovery.

Though a single supercapacitor cell will provide 2.7 V, higher voltages can be achieved by connecting several supercapacitors in series. Just as with lithium-ion batteries, supercapacitors in a stack might not have the same capacitance due to manufacturing or uneven aging. Strings of more than three capacitors require voltage balancing to ensure long operational life, preventing overvoltages by keeping the voltage on each cell as low as possible to achieve the needed total stack voltage.

Power-Management Supercapacitors

Engineers can choose from various devices designed specifically to manage the unique requirements of supercapacitor charge, depending on the application.

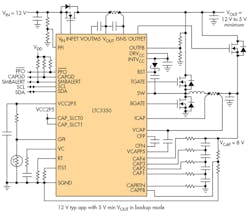

Linear Technology, for example, offers its LTC3350 (Fig. 6), a backup power controller that can charge and monitor a series stack of up to four supercapacitors. The LTC3350, designed for automotive and other transportation applications, offers the following features:

• Power backup by charging a bank of up to four supercapacitors in case of a power failure. It can handle 4.5- to 35-V input voltage and over 10 A of charge/backup current.

• Balancing and overvoltage protection to the series stack of supercapacitors.

• Monitoring of system voltages, currents, and die temperature.

• Internal capacitor voltage balancers that eliminate the need for balance resistors.

Intersil’s ISL78268 is a synchronous buck controller designed to support an input voltage range of 5 to 55 V. The buck controller integrates a peak current mode control for PWM generation and a constant average current loop ideal for supercapacitor charging. With an ISL78268, it’s possible to charge a bank of capacitors using a constant-current/constant-voltage (CICV) methodology. In addition to supercapacitor charging, the ISL78268 is also suited for automotive power and telecom power supplies.

Maxim’s MAX13256 H-bridge transformer driver is another solution for charging supercapacitors while simultaneously driving a system load. The addition of a small diode and resistor in parallel between the supercapacitor’s positive lead and the output of the transformer circuit limits the current used to charge the supercapacitor during normal operation. It also allows for easy discharge when energy is required.

Advances made in supercapacitor capacity and energy density will ultimately lead to greater functionality and more overall presence of the devices throughout the energy industry. Based on all of their inherent advantages, supercapacitors should help reduce the costs to the customer by minimizing the amount of batteries needed, as well as the frequency of battery replacement.

Supercapacitor Standards and Standardized Test

While testing can assure customers whether supercapacitors are reliable, manufacturers are not required to comply with a specific standard or test. A few standards intended for supercapacitors let manufacturers voluntarily test their products using different methods.

Some of the more commonly used standards and tests for supercapacitor include:

• Restriction of Hazardous Substances (RoHS) Compliance: This European directive specifically ensures that no hazardous materials restricted by Europe are involved during the product manufacturing process. It restricts the use of six hazardous materials (lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls, and polybrominated diphenyl ether) in the manufacturing process of electronic and electrical equipment.

• IEC 60068-2-27 and 2-29: These shock standards assure that a product is durable in rugged, high-demand applications, and that it can handle sudden applied forces and shocks.

• REACH Compliance: REACH stands for the Regulation, Evaluation, Authorization and Restriction of Chemicals. The sole purpose of REACH is to address the production and use of chemical substances, and their potential impacts on both human health and the environment.

• UL 810A: The standard was developed by UL especially for supercapacitor technology. The requirements of this test cover supercapacitors being used in equipment such as electronic products, uninterruptible power supplies, emergency lighting, engine starting, and power equipment.

• IEC 62576: This standard describes methods for testing basic electrical characteristics (capacitance, voltage maintenance, and energy efficiency) of conventional electric double-layer capacitors (EDLCs) to be used for peak power assistance in hybrid electric vehicles.

• IEC 62391-2: This is for fixed EDLCs for use in electronic equipment and EDLCs for power application.

As the presence of supercapacitors increases in the power electronic market, the need for a single standard keeps rising, too. It will be easier for customers to have just one standard in mind when deciding which supercapacitor to buy. Right now, for example, there are several methods for ESR testing (e.g., IEC6231, EUCAR, manufacturers’ own methods).

About the Author

Maria Guerra

Power/Analog Editor

Maria Guerra is the Power/Analog Editor for Electronic Design. She is an Electrical Engineer with an MSEE from NYU Tandon School of Engineering. She has a very solid engineering background and extensive experience with technical documentation and writing. Before joining Electronic Design, she was an Electrical Engineer for Kellogg, Brown & Root Ltd (London. U.K.). During her years in the Oil and Gas Industry she was involved in a range of projects for both offshore and onshore designs. Her technical and soft skills bring a practical, hands-on approach to the Electronic Design team.