Designers can use a new IC family from Linear Technology to break large battery packs into smaller modules for electric vehicles and other applications. The LTC6804 battery pack monitor analog front end (AFE) and its complementary LTC6820 controller can be used to monitor multiple batteries, while the LTC3300 and LTC8584 perform the battery balancing.

Modules are valuable because, otherwise, fitting 16 kWh worth of batteries into a single compartment would be problematic. Also, modularization can facilitate serviceability. It allows scalability as well, as sedans and sports vehicles may have different battery stacks made of common modules.

Voltage Sensing

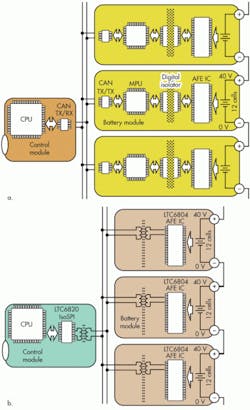

Modularization can lead to greater complexity in the wiring harness and potential electromagnetic interference (EMI) susceptibility related to longer copper runs. The standard approach to battery monitoring in modularized systems uses a CAN bus as the link and microprocessors to convert the CAN protocol to a simpler SPI or I2C protocol for the monitoring AFE. A digital isolator IC that sometimes requires an isolated power supply provides isolation between modules (Fig. 1).

1. Contemporary production vehicles with modular battery packs have used a combination of CAN communications and digital isolators to interface the modules (a). In Linear Technology’s alternative approach, multiple ICs are connected using the company’s proprietary two-wire isoSPI interface, using the LTC6820 isoSPI transceiver and a simple Ethernet transformer (b).

Each LTC6804 battery pack monitor can measure up to 12 series-connected battery cells at voltages up to 4.2 V with 16-bit resolution and better than 0.04% accuracy. A sub-surface Zener voltage reference similar to references used in precision instrumentation maintains this precision over time, temperature, and operating conditions. For precision, the Zener is preferable in this application to a band-gap reference.

Stacked in series, LTC6804s enable the measurement of every battery cell voltage in large high-voltage systems. Six operating modes optimize the update rate, resolution, and low-pass response of the built-in third-order noise filter. In the fastest mode, all cells can be measured within 290 µs.

Multiple ICs are connected using Linear’s proprietary two-wire isoSPI interface, by means of the LTC6820 isoSPI transceiver and an Ethernet transformer. This configuration provides for bidirectional transmission, at rates up to 1 MHz, up to 100 meters across an isolated barrier. Different dash-number LTC6820 devices can be daisy-chained with a single host processor connection for all, or else connected in parallel to the host processor, with each device individually addressed.

In sleep mode, each device draws less than 4 µA from the batteries. General-purpose I/O pins are available to monitor analog signals, such as current and temperature, which can be captured simultaneously with the cell voltage measurements. Additional features include passive balancing for each cell with a programmable balancing timer for up to two hours, even when the LTC6804 is in sleep mode.

The LTC6804 interfaces with external I²C devices such as temperature sensors, analog-to-digital converters (ADCs), digital-to-analog converters (DACs), and EEPROM. Local EEPROM can be used to store serialization and calibration data, enabling modular systems.

Battery Balancing

Balancing is required in any array of series-connected batteries because self-discharge rates, electronic loads, and temperatures differ from cell to cell. Over many charge and discharge cycles, these differences result in imbalances in cell state of charge (SoC). In turn, this charge imbalance reduces pack capacity.

For example, if one cell has 10% more charge than the others, and a charging current is applied to the pack, this particular cell will reach the 80% state of charge limit while the other cells are charged to only 70%. In that case, the available energy in the pack has been reduced by 10%.

There are multiple solutions. Passive balancing, the dissipation of a single cell’s charge through a load resistor, is the lowest cost and simplest way to balance mismatched cells in a series stack. Although it is simple, passive balancing is inefficient and slow.

Typical passive balancing currents range from 1% to 5% of the cell capacity. Dissipating 10% of the charge from a 40-Ah battery requires 10 hours at 400 mA, or, charging at 2 A, passive balancing generates 8 W of heat per cell. For large-capacity packs, the generated heat becomes unacceptable.

In contrast, active balancing not only speeds charging with less heat, it also helps recover capacity that cells lose as they age. Over time, each cell ages differently, due to gradients in pack temperature and differences in cell manufacturing.

The significance of this is that, with passive balancing, a pack’s capacity is determined by its weakest cell. That’s because the pack is balanced and charged to 80%. The discharging of the pack is halted when the weakest cell reaches 20%.

A properly designed active balancing system will efficiently redistribute charge throughout the stack as needed to ensure that the 20% and 80% points are reached based on the average-capacity cell rather than the lowest-capacity cell.

Balancing ICs

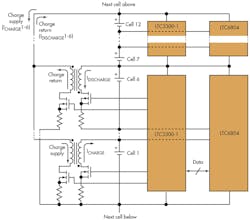

To maximize battery pack run time, cells must be balanced during both the charging and the discharging of the battery stack. The LTC3300 addresses this bidirectional active balancing need (Fig. 2).

2. The LTC3300 uses a non-isolated synchronous flyback topology to balance up to six cells at a time from 12 or more neighboring cells.

With the LTC3300, balancing currents up to 10 A are possible. Charge is transferred from one 12-cell module to the next by interleaving the secondary side connections of each flyback transformer. Transfer efficiencies greater than 92% are achievable, along with better than 80% capacity recovery for typical cell-to-cell mismatch conditions. The LT3300 can be controlled via a serial port on the LTC6804.

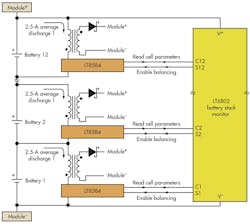

Alternatively, the LT8584 monolithic flyback dc-dc converter accomplishes active balancing using a unidirectional topology (Fig. 3). The unidirectional approach redistributes charge from a given cell to the entire stack of cells. An integrated 6-A power switch supports 2.5 A of average balance current. The LT8584 can also measure balance current, die temperature, and cable resistance. Like the LTC3300, it connects directly to the LTC6804.

3. Linear’s LT8584 flyback dc-dc converter accomplishes active balancing using a unidirectional topology.

Priced at $10.95, the LTC6804 comes in an 8- by 12-mm surface mount package. The LTC6820 is packaged in mini small-outline package (MSOP) and quad flat no-lead (QFN) formats and costs $2.29. The LT3300 and LTC8584 are sampling now. Firm pricing will not be set until April and May.

Linear Technology