Design Touchscreen-Based Handheld Systems For Low Power Consumption

This file type includes high resolution graphics and schematics.

Low-power operation is one of the major design aspects of any touchscreen device. Power efficiency helps to extend battery life, satisfying a primary design constraint for increased operating life. Power-efficient design also helps reduce the battery size and, hence, the end system’s size and weight, which are also important specifications. In addition, power efficiency reduces the overhead required to manage thermal dissipation because the generation of heat is reduced at the source by optimizing the power consumed.

Designers can stretch the operating battery life of handheld devices through judicious management of the operational states. Touchscreens, which are now nearly ubiquitous, make a good example. The operating conditions for a portable device, with the variety of applications it can support, generally can vary from intensely busy to nearly idle in a moment’s time. By utilizing knowledge of how a device is being used, the power consumed by the touchscreen can be more efficiently managed.

Most embedded systems incorporate several subsystems. In a smart phone, these include the touchscreen interface, wireless module, and battery charging. Total system power consumption is the cumulative power consumption of all these different blocks in the system. Most of these blocks have independent controllers that communicate with the host processor. Thus, each block is more or less an independent entity in terms of system design and must be optimized to minimize the overall power consumption of the system. In particular, carelessly designed touchscreens can cause the system’s battery to drain very quickly.

Power Consumption Basics

There are two major components of power consumption in a CMOS circuit: dynamic power consumption and static power consumption. Dynamic power consumption is due to the switching outputs from logic high to low and vice versa. Overall power consumption can be managed by controlling either dynamic or static power or both.

In CMOS-based designs, circuits dissipate power by charging and discharging load capacitances. Considering the internal architecture of a touchscreen controller, load capacitance is nothing but the gate capacitance of the next stage or the bus capacitance.

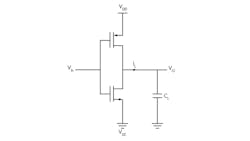

Power is dissipated across a PMOS transistor when the load capacitor is being charged and across an NMOS when load capacitor is being discharged. Instantaneous power dissipation across an NMOS transistor in a CMOS inverter (Fig. 1) is given by:

PPMOS i = iL(VDD – VO) [1]

After substituting the value of iL:

PPMOSi = CL(VDD – VO)dVO/dt [2]

1. In a basic CMOS inverter, power is dissipated across a PMOS transistor when the load capacitor is being charged and across an NMOS when the load capacitor is being discharged.

Total power dissipation across the PMOS to switch the output from low to high can be determined by integrating power dissipation across the PMOS to charge the load capacitor from 0 V to VDD:

PMOS power consumption, PPMOS = ½ CLVDD2 [3]

Similarly, to switch the output from high to low, total power dissipation across the NMOS is:

NMOS power consumption, PNMOS = ½CLVDD2 [4]

For one complete switching cycle, the power dissipation is:

PTotal = PNMOS + PPMOS = CLVDD2 [5]

Defining the average power in terms of switching frequency (f):

P = fCLVDD2 [6]

Several factors influence static power consumption, including sub-threshold conditions and tunneling current. Tunneling current becomes dominant when the transistor is scaled down for compact chip design, because reduced dimensions result in a reduction in oxide thickness.

Handheld mobile devices integrate several component blocks such as the LCD driver, touchscreen controller, power management, and communications link. In touchscreen-based phones, the touchscreen controller can be a power sink if it isn’t designed for efficient power. An appropriate touchscreen controller must be selected and configured so it consumes minimal power.

Touchscreen Controllers

Most simple microcontrollers essentially have two power modes: active and sleep. A touchscreen controller, however, isn’t so simple. (For example, it incorporates an analog front end for capacitance measurement.) Touchscreen controllers, then, often offer more granular handling of power consumption, which typically takes the form of additional power. Common power modes for touchscreen controllers include:

• Active power: The CPU and other resources on the chip are up and running. Static and dynamic power consumption both contribute to the total power consumption in this mode, which is the most commonly used mode for most of the controllers and processors in the industry. (Even here, however, the CPU can power down some clocks and resources in touchscreen controllers, based on system requirements. This makes the touchscreen controller more sophisticated than basic controllers. Nevertheless, this mode requires more power than any other. It sets a baseline for the design of the battery system.)

• Sleep: This is another familiar power mode for most controllers. Primarily, it involves the CPU going to sleep (i.e., its clock is disconnected). The only contribution by the CPU toward the total power consumption is static power consumption, since there is no clocking.

• Deep sleep: In this mode, the system clock is disabled, so none of the high-frequency resources (CPU registers, SRAM, etc.) is available. However, their previous state is retained. Because the high-frequency clock is disabled, a lot of power that would have been consumed due to switching is conserved. Deep sleep modes generally provide an option to keep running a low-frequency clock that can be used to drive some low frequency-resources such as a timer. Additionally, this mode allows the designer to employ communication protocol blocks such as an I2C slave that do not require any clock generated by the device itself. The usual way to enter this mode is to disable the main system clock to the system while keeping the blocks powered up. The only battery drain in this mode comes from the static power consumption of all the blocks on the chip.

• Hibernate: In this mode, all the clocks are switched off and power is removed from all chip resources in the chip, except for those used as a wakeup source when triggered by an external event. As almost everything is powered down in this mode, it yields the lowest power.

Average current consumption for the system is:

Touchscreen Sensor Controller Options

Controllers provide for following a logical series of states for device operation (Fig. 2). Generally, the amount of time the system remains in active and various low-power modes depends on the application. Certain applications may need to have the controller running all the time, and others may require it to run only occasionally. System designers must consider power consumption in the specific mode in which their system must spend most of its time to ensure that their designs are power-efficient.

2. State diagrams, such as this one for the Cypress TrueTouch Gen4 controller, aid designers in programming power states.

In some applications, it could prove beneficial for the system to run at a higher speed so it can complete its job and get into the low-power mode faster. For other applications, the CPU can run at a slower speed that keeps active power consumption low without entering low-power mode. Here, the system designer has to analyze the best case for the application considering the current at different operating speeds; the time it takes to come out of low power mode; current consumption in low-power mode; and the frequency with which the system needs to switch between active and sleep modes.

Touchscreen controller programming can help reduce total system power consumption in four ways: reducing the time during which the system needs to remain in active mode; increasing the signal-to-noise ratio (SNR) by choosing the right operating voltage; taking advantage of greater CPU power; and allowing system designers to select the time the controller needs to remain in a particular power mode.

SNR is one of the most important parameters in defining touchscreen reliability. Noise from a display or charger can drastically impact touchscreen performance, including an increased risk of false touches. The higher the SNR of a device is, the better the touchscreen performance is in noisy environments.

To ensure there are no false triggers, samples need to be filtered if SNR is poor. Higher transmit voltage helps in achieving better SNR. So, empowered by high SNR, touchscreens with higher transmit voltage need fewer samples to be filtered, resulting in less time needed to process these samples to achieve the same accuracy as would otherwise be required over longer times with a lower SNR. The controller, therefore, needs to remain in the active mode for less time to achieve a particular refresh rate. The Cypress TrueTouch Gen4 controller, for example, has 10-V transmit to provide a high SNR.

Even though the voltage at which the touchscreen panel is driven is greater, the improvement in SNR improves performance in terms of reducing false touches in the presence of noise, while shortening the filtering cycle to use less power.

When it comes to the CPU, more measurement precision is better. That higher precision made possible by a better SNR makes it practical to use a controller with a 32-bit ARM M-Cortex core, providing faster throughput (e.g., a 60-Hz refresh rate for two-finger touch, while keeping active power to 2 mW).

Enabling system designers to select the time the controller needs to remain in a particular power mode is one of the most important aspects of touchscreen system design. The system designer should be able to select an optimal refresh rate based on the kind of application running on the mobile device and the user’s battery life preferences. Real-time updatable register-configurable resources in the controller, for example, give system designers better control over power modes and the durations in which a system remains in any particular mode.

An important factor in improving the overall power consumption in handheld devices is to increase processing speed so the time the controller requires to remain in active mode decreases. Additionally, putting the controller in low-power modes for longer periods of time helps reduce the average power consumption.

In particular, a touch panel’s refresh rate determines the length of time in which the controller remains in active and low-power modes. Also, refresh rate requirements are different for different applications; i.e., a gaming application will need a higher refresh rate than an application used for making phone calls. Based on the application, the designer must ensure that the refresh rate is controlled dynamically to achieve higher battery life. A touchscreen controller that can deliver low active power in the presence of multiple touches with a fast refresh rate is the best choice for system designers looking to maximize the battery life of their handheld devices.

This file type includes high resolution graphics and schematics.

About the Author

Sachin Gupta

Staff Product Marketing Engineer

Sachin Gupta is a Staff Product Marketing Engineer in the IoT business unit with Cypress Semiconductor. He holds a Bachelor’s degree in Electronics and Communications from Guru Gobind Singh Indraprastha University. He has nine years of experience in SoC application development and product marketing.