Graphene Sheets, Wrinkled and Crumpled, Make Better Batteries

Engineers from Brown University have found that crumpled sheets of graphene can help bolster the electrochemical properties of rechargeable batteries. When used as a battery electrode, the wrinkled material has been shown to provide a current density 400% greater than flat graphene.

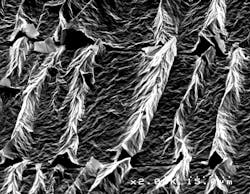

The research focused on crumpling sheets of graphene oxide, an extremely thin lattice of carbon, hydrogen, and oxygen molecules. When wrinkled and crumpled enough, the researchers discovered that graphene not only becomes more conductive, but also gains new physical characteristics. It becomes remarkably stretchy and pliable, which could make it useful in stretchable electronics, such as wearable sensors that conform to the contour of the skin.

The researchers crumpled the graphene by fixing the material onto shrink films — more commonly known as Shrinky Dinks — that contract when heated. As the film shrinks, the graphene is compressed, forming crumples and wrinkles. The researchers subjected material to this process multiple times, dissolving the shrink film and then reattaching the graphene to another film.

The engineers tried shrinking the material in many different ways. One involved clamping opposite ends of the film to form parallel wrinkles. Another left the film unclamped, free to morph into random shapes. Shrinking the material multiple times with different methods led to increasingly complex wrinkles. In one experiment, they shrunk the material with clamps, then again without clamps, and used the clamps again the third time. Sometimes, rotating the graphene in between each stage would produce unique shapes.

An unexpected discovery was that wrinkles could be superimposed on each other. “As you go deeper into the generations you tend to get larger wavelength structures with the original, smaller wavelength structure from earlier generations built into them,” says Robert Hurt, an engineering professor at Brown who worked on the team’s research, which was published in the journal Advanced Materials.

The most important result of the wrinkling process was vastly increasing the surface area of the graphene in an extremely small space—an ideal quality for high-density battery electrodes. After shrinking a sheet of graphene oxide three times, it became as small as 1/40 its original size.

With its high thermal conductivity and electron mobility, graphene has been studied to increase the energy density of lithium-ion batteries. However, widespread use of the material hinges on the ability to produce it in large quantities and at low cost. There have been efforts to enhance graphene’s latent properties so that its benefits would outweigh manufacturing costs.

The researchers, though, were not originally inspired to create more advanced batteries. Instead, the project grew out of previous work by Hurt and Ian Wong, a fellow researcher from Brown’s engineering school. Last year, they wrinkled sheets of graphene to make complex substrates for growing cell cultures. The wrinkled and uneven material more closely resembled the complex environments in which cells form in the human body—like more realistic Petri dishes.

Po-Yen Chen, one of the co-authors of the battery research, was intrigued by the thought of making more complex structures. “I wanted to see if there was a way to create higher-generation structures,” says Chen. Following the experiments, the researchers compiled a kind of taxonomy taken from the different shrinking recipes they tried. Each structure was tested to see how they altered the properties of the graphene sheets.

Now, the researchers are planning to test new ways of generating wrinkles and structures on graphene and other two-dimensional materials. “Other materials or combinations of materials may also organize into interesting structures with unexpected functionalities,” Wong said.

About the Author

James Morra

Senior Editor

James Morra is the senior editor for Electronic Design, covering the semiconductor industry and new technology trends, with a focus on power electronics and power management. He also reports on the business behind electrical engineering, including the electronics supply chain. He joined Electronic Design in 2015 and is based in Chicago, Illinois.