Informed Analysis Picks Better 555 Timer To Drive Power MOSFET

This article is part of the Ideas for Design Series: Vol. 3, No. 1

The original bipolar 555 timer, the NE555, is excellent for driving a power MOSFET’s gate. Newer CMOS versions such as the 7555, LMC555, and TLC555 use less power, but they have trouble sourcing enough current to drive a gate well and can even be damaged by load mismatch.

This file type includes high resolution graphics and schematics when applicable.

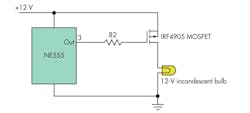

The figure shows part of a pulse-width-modulated dimmer for a 12-V incandescent lamp. It originally used a CMOS TLC555, which kept failing with an open output pin as the failure mode. In addition, the MOSFET (an IRF 4905) ran hot. Pin 3 of the 555 was connected directly to the MOSFET gate.

Examination with an oscilloscope showed that the gate voltage had a rise and fall time of about 2 µs and that the pulse-width modulation (PWM) switching frequency was about 100 kHz, so about 40% of each cycle was spent on the rise and fall. That explained why the MOSFET was running hot. Much of the time, it was neither fully on nor fully off, but in the lossy intermediate-state switching-transition mode.

The input capacitance of the IRF 4905 is typically 3500 pF. Using the well-known current-charging equation I = C dV/dt, we find that the gate charging and discharging current with a 12-V square wave is about 21 mA, twice the rated output of the CMOS 555. That explains the failures.

The solution was simple. The timer chip was changed to a bipolar NE555 (rated for 200-mA sink and source current), an 82-Ω resistor was added to guarantee that the current would always be below 150 mA, and the switching frequency was reduced to 3 kHz to reduce the proportion of time spent “on the slope.” The resulting circuit performed more reliably, and the MOSFET did not even get warm.

Michael Covington, PhD, operates a consulting practice, Covington Innovations (www.covingtoninnovations.com), in Athens, Ga.

Read more articles from the Ideas for Design Series: Vol. 3, No. 1

About the Author

Michael Covington

Consultant

Michael Covington, PhD, operates a consulting practice, Covington Innovations (www.covingtoninnovations.com), in Athens, Ga.