Intelligent Energy Optimization System Slashes Large-Scale Electric Bills

Sometimes, age-old problems should be looked at with a new perspective. That’s what engineers at Power Metrics International (PMI) did when they devised a patent-pending optimization technique in electric power management that addresses inefficiencies in power delivery and usage.

The SP1000 series of hybrid energy management and correction systems guarantees and quantifies kilowatt-hour savings by reducing losses in power delivery, identifying and reducing harmonics, correcting for system imbalance, increasing equipment efficiency, and optimizing power utilization. Reductions in kilowatt-hours of 3% to 7% have been regularly observed. Total electric bill reductions of 8% to 15% have been achieved. User return on investment (ROI) typically ranges from 15 months to two years.

The SP1000 continuously measures current, harmonics, load-source imbalances, and power factor at a rate of 128 samples per cycle then corrects for all of these parameters on the fly. It also stores data in 5-minute increments for more than 15 months. It is designed and tested by PMI and manufactured by MHT, which produces high-efficiency lighting products.

The board uses a conventional off-the-shelf triac and state-of-the-art, proprietary, long-life switches (rated for on and off switching times of millions before burnout like other types do), as well as small capacitors (Fig. 1). It dissipates one-tenth the wattage of similar products during switching. The hybrid system is available in three versions: the 208-V SP1000A (10 kVAr or kilovolt-ampere reactive), the 208-V SP1000B (17 kVAr), and the 480-V SP1000E (30 kVAr).

1. The SP1000 hybrid energy management and correction system board (top) and its capacitors (bottom) fit in an electrical subpanel. The system takes up little space yet saves a lot on electric bills.

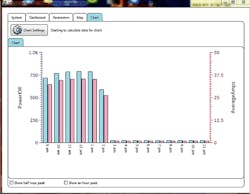

The system’s SPIDER (Sensor Perfect Interface Data Exchange Routines) software supports constant power-consumption monitoring and management. It gives users a “dashboard” view of readings in real time in charts. Also, it highlights issues like motor deterioration, allowing users to be proactive instead of reactive in their maintenance (Fig. 2).

2. An hourly view of the SP1000 hybrid energy management and correction system provides a view of how a facility’s current levels (red) correspond with the power consumed in kilowatts (blue).

The system makes thousands of decisions per minute, based on what it is reading through external and internal current transmitters. It addresses harmonics, voltage imbalance, temperature rise and fall, loss of current, and other issues within the facility while increasing motor efficiency and reducing the operating temperature.

Underwriters Laboratories (UL) has approved the SP1000 system under Section 508. According to PMI executive vice president Robert Turner, it is the only system on the market that can monitor, record, and quantify true kilowatt/kilowatt-hour savings at this price point.

The unique SP1000 also monitors each leg of a three-phase panel independently from the other two legs and then applies capacitance to each leg based on the load characteristics and arbitration between all governing parameters, says Hamid Pishdadian, who invented the SP1000’s architecture and holds the patent application. Other techniques used by other companies such as power factor correction (PFC) are based on average usage basis, which isn’t efficient.

Pishdadian points out that it is important to keep the power factor (real power divided by apparent power) as close as possible to 1, which the SP1000 does. This produces a smaller utility bill since electric companies charge customers with power factors less than 0.95 an additional fee.

An improved PFC also increases internal electrical system capacity since unconnected power increases losses in the electrical distribution system and limits capacity for expansion. The voltage drop at the point of use also is improved. Voltages below equipment rating reduce efficiency, increase current, and reduce starting torque in motors.

SP1000 boards have already been installed in the field, and customers have given them high ratings. One customer says his electric power consumption during an identical four-month period from a previous year dropped by more than 12%. Another said he saved at least 16% per month in his electric bill during the summer, savings that are continuing, despite the fact that he was reticent at first to try the SP1000 units at his site.

MHT Lighting

Email: [email protected]About the Author

Roger Allan

Roger Allan is an electronics journalism veteran, and served as Electronic Design's Executive Editor for 15 of those years. He has covered just about every technology beat from semiconductors, components, packaging and power devices, to communications, test and measurement, automotive electronics, robotics, medical electronics, military electronics, robotics, and industrial electronics. His specialties include MEMS and nanoelectronics technologies. He is a contributor to the McGraw Hill Annual Encyclopedia of Science and Technology. He is also a Life Senior Member of the IEEE and holds a BSEE from New York University's School of Engineering and Science. Roger has worked for major electronics magazines besides Electronic Design, including the IEEE Spectrum, Electronics, EDN, Electronic Products, and the British New Scientist. He also has working experience in the electronics industry as a design engineer in filters, power supplies and control systems.

After his retirement from Electronic Design Magazine, He has been extensively contributing articles for Penton’s Electronic Design, Power Electronics Technology, Energy Efficiency and Technology (EE&T) and Microwaves RF Magazine, covering all of the aforementioned electronics segments as well as energy efficiency, harvesting and related technologies. He has also contributed articles to other electronics technology magazines worldwide.

He is a “jack of all trades and a master in leading-edge technologies” like MEMS, nanolectronics, autonomous vehicles, artificial intelligence, military electronics, biometrics, implantable medical devices, and energy harvesting and related technologies.