Download this article in PDF format.

Fitness bands that monitor and track heart rate, breathing, activity, and other fitness-related data are now everyday consumer items, but they’re only the most visible piece of the larger wearable health, fitness, and medical segment. Now wearable devices are beginning to transform medical care in both the hospital and the home, helping to reduce costs, increasing patient involvement in their own care, providing round-the-clock monitoring, and even administering medications based on a preset schedule.

Wearable medical devices can monitor a broad range of clinical measurements: heart rate and breathing, as well as diagnostic indicators like oxygen level, glucose levels, hydration, blood pressure, skin conductance, temperature, brain activity, and many more. The data is then logged and communicated wirelessly to the medical staff, who have a permanent record and early warning of potential problems.

Sponsored Resources:

1. Like many other medical monitoring technologies, the ECG has progressed from an expensive fixed-base machine to a low-cost wearable appliance. (Source: TI “Advances in bio-inspired sensing help people lead healthier lives” PDF)

The transition from a cumbersome fixed-base installation to a tiny module that the patient barely notices has been a long time coming (Fig. 1). For example, when the first electrocardiography (ECG) machine appeared in 1908, it required five people to operate and the patient had to place each limb in a bucket of salt water. Still, that was a vast improvement over what had gone before: Until the late 1800s, medical scientists could only record heart activity by directly examining the heart. Of course, its owner had to be dead, but still….

Current-generation medical wearables do much more than just monitor the patient’s heartbeat. They combine multiple functions into a single biosensor. VitalConnect’s clinical-grade VitalPatch, for example, contains ECG electrodes, a three-axis MEMS accelerometer, and a thermistor. In addition to heart rate, the patch provides real-time monitoring of respiratory rate, skin temperature, and metrics such as body posture, activity level, and fall detection. Hospital staff can access the information via web-enabled devices on the hospital network.

Must Reduce the Power

One characteristic is common to just about all handheld and wearable products: Each new generation includes more features and higher performance than the one it replaced. This combination of features normally increases the power consumption, but wearable devices are battery-powered, and increasing the physical size of the battery is usually not possible because a smaller package is also a typical product requirement.

The simplest solution might be to allow the user to just replace the battery with a fresh one and recharge the spent unit offline. For the designer, though, sealing the battery into the case brings a host of advantages—it frees up room for added features; provides the flexibility to vary the battery shape beyond the standard rectangle; allows for a smaller, slimmer package; and improves resistance to water and dust ingress.

As a result, removable batteries have mostly disappeared from smartphones, fitness bands, and similar devices. Medical wearables have more stringent requirements than consumer devices. They must be impervious to a wider range of chemicals, including solvents and body fluids, and the battery must last for several days at a time.

Since a replacement battery isn’t an option, squaring the circle requires a multi-faceted design solution, with innovation in both the supply and demand sides of the equation. The two obvious options are:

- Supply: Improve the performance of the battery itself so a smaller battery can hold more energy.

- Demand: Reduce the power consumption of the wearable electronics to increase the run-time of the selected battery

On the supply side, there continues to be incremental improvement in the performance of Li-ion batteries, and other chemistries are slowly making their way to production. However, most of the work is taking place on the demand side, where integrated-circuit manufacturers are designing components from the ground up for minimum power consumption in every mode of operation.

The parts in a wearable application must be power-efficient during normal operation, but many wearables only need to take measurements—of heart rate, for example—at intervals, and can spend most of their time in a low-power sleep state. Thus, most devices include the ability to switch to a low-power mode and wake up quickly on demand.

TI’s MSP430 family of ultra-low power microcontrollers (MCUs) is a good example. In addition to a comprehensive set of peripherals, MSP430 devices include multiple low-power modes and are optimized for extended battery life in portable and wearable applications.

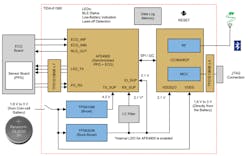

2. This pulse oximeter reference design measures only 0.609 × 0.413 inches. (Source: TIDA-00311—Miniaturized Pulse Oximeter Reference Design)

These low-power features are leveraged in TI’s miniaturized pulse oximeter reference design (Fig. 2). The controlling MSP430F5528 consumes only 1.9 µA in standby mode with a 2.2-V supply. The reference design’s AFE4403 integrated analog front end (AFE) is optimized for this applications, so it features a dynamic power-down mode to shut off blocks during the unused section of each pulse repetition period.

Another medical wearable reference design (Fig. 3) implements a multiparameter patient monitor that uses the AFE4900 single-chip biosensing front end to provide synchronized electrocardiography (ECG) and photoplethysmography (PPG) measurements. A CC2640R2F Bluetooth Low Energy (BLE) microcontroller then transfers the measured data to a nearby tablet or smartphone. The MCU, which uses a 32-bit Arm Cortex-M3 core running at 48 MHz, is optimized for long battery life, small-form-factor applications.

3. The TIDA-01580 reference design is a multi-parameter patient monitor based on the AFE4900 biosensor. (Source: TI Designs: TIDA-01580 “Wearable, Wireless, Multi-Parameter Patient Monitor Reference Design” PDF)

The raw data is available for calculating standard clinical metrics: heart rate, oxygen concentration in blood (SpO2), pulse transit time (PTT), and ECG. Two onboard light-emitting diodes (LEDs) indicate low-battery detection and ECG lead-off detection for users.

Although this design uses a replaceable battery, low power consumption is still a top priority. For example, the CC2640R2F MCU features low current consumption in both active and low-power modes. It includes a sensor controller that’s able to gather analog and digital data autonomously while the rest of the chip is in sleep mode. The complete reference design can operate for 30 days from a single CR3032 coin cell.

New Solutions Increase Battery-Charging Efficiency

In parallel with efforts to reduce power consumption, there’s a continuing push to improve the performance of the charging system to maximize the battery charge and minimize the time spent out of service.

Texas Instruments has developed several reference designs to help engineers develop ultra-low-power battery-charging circuits for consumer products. Many of the design techniques are directly applicable to medical wearables with equivalent requirements.

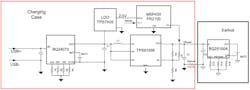

Wireless earbuds, for example, are charged by the battery inside their carrying case. The charger must have high efficiency coupled with small size. Figure 4 shows an ultra-low standby power reference design for a wireless earbud battery-charging system. The design can supply up to 1.5 A for fast charging with a charging accuracy of 1 mA.

4. A battery-charging system for a wireless earbud relies on USB power. (Source: TI Designs: TIDA-050007 “Ultra-low Standby Power Reference Design for Wireless Earbuds Battery Charger PDF)

Most of the circuitry resides in the earbud charging case. The bq24073 Li-ion battery charger gets power from its USB input and charges battery BAT1, as well as supplying the TPS61099 synchronous boost converter that provides power to the earbud battery BAT2. The earbud contains the bq25100A battery charger, which allows precise control of the charging cycle of the earbud’s 250-mA single-cell Li-ion battery. Both chargers follow the characteristic three-phase Li-ion charging profile: conditioning, constant current, and constant voltage. BAT1 supplies charging current in the absence of a USB connection.

Thanks to the low charging current, a linear topology can be selected for both battery chargers. The linear designs are more compact and lower-cost than equivalent switching designs because they don’t require large and expensive inductors. Although the thermal performance of the linear charger isn’t as good as the more-efficient switching design, it’s adequate for this application. The switcher would be preferable at higher current levels.

A TLV713P 150-mA low-dropout regulator (LDO) supplies the 2.5-V power rail for an MSP430FR2100 microcontroller that monitors the charging current and controls the output voltage of the TPS61099 boost converter.

The charger reference design supports pass-through mode when the USB input voltage is higher than the required output voltage. The design achieves an efficiency higher than 85% and has a standby current of only 18 µA.

Energy Harvesting: An Electronic “Free Lunch”?

As the power consumption of the components continues to decrease, medical wearable designers can investigate new ways of charging the battery using energy harvesting. In other words, make use of ambient energy that would otherwise be wasted.

Solar energy, triboelectric energy from static charge, kinetic energy from motion, and heat can all be converted to electrical energy. The energy would then supplement a wearable battery and extend the time between charging cycles. Ideally, a device could be completely powered by ambient energy and eliminate the battery entirely.

Increasing the efficiency of the conversion devices is an area of active research. The latest dye-sensitized photovoltaic (solar) cells (DSSCs), for example, can output 20-25 µW/cm2 of power at an illuminance of 200 lux (lumens/m2)—a much lower lighting level than the 600-1500 lux found in a typical office.

Thermoelectric generators (TEGs) based on thin-film technology hold promise, and researchers have even demonstrated thermoelectric structures composed of nanowires 1-2 atoms in diameter. Due to the naturally occurring heat sources in the human body, TEGs hold much promise in boosting battery life in implantable medical devices.

Wearable devices are very small, so there’s limited surface area to mount a solar cell or room to add a TEG. Consequently, the harvested power is very small—microwatts to milliwatts—and the raw output voltage must be boosted to a useful level. However, it’s still sufficient for ultra-low-power ICs such as the MSP430 MCU and other devices mentioned above.

Texas Instruments offers a family of ultra-low-power energy-harvesting ICs that are suitable for a wide range of medical fitness and industrial applications. The ICs accommodate multiple energy-storage technologies, including batteries (Li-ion, Li-polymer, lead acid, NiMH, and NiCd chemistries) and supercaps.

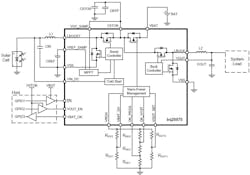

5. The bq25570 is an efficient way to harvest energy from solar cells and similar sources. (Source: TI E2E: “Self-powered medical monitoring devices: Harnessing free ambient energy”)

The bq25570 ultra-low-power harvester and power-management IC is designed to efficiently extract power from high-output-impedance solar cells or TEGs without collapsing those sources (Fig. 5). The device integrates both a highly-efficient boosting charger and a nano-power buck converter that provides a second power rail to systems with stringent power and operational demands, such as wireless sensor networks (WSN).

Because the extracted power can vary widely, the bq25770 includes battery-management features to ensure that the rechargeable battery remains within its safe operating area (SOA) at all times—neither overcharged or depleted beyond safe limits during discharging. The device comes in a tiny 20-lead, 3.5- × 3.5-mm QFN package. Similar devices include the bq25504 and bq25505.

Conclusion

Wearable devices represent the current and future wave in medical care. They hold promise in multiple areas from real-time patient monitoring to drug delivery, but the small space available for a battery imposes strict constraints on the designer, particularly in the area of power consumption.

Texas Instruments offers a range of products and reference designs that demonstrate how its low-power devices can add value to a broad range of medical wearable products. Find out more information at the medical, healthcare, and fitness portal.

Sponsored Resources: