The evolution of battery technologies is directly tied to the miniaturization of mobile electronics such as cell phones, laptops, and tablets. As these portable devices get smaller, the battery cells and packs that power them have shrunk accordingly. For example, the design trend for smaller portable and handheld electronics is what originally spurred the rapid proliferation of rechargeable lithium-ion (Li-ion) batteries. Yet the applications engineers who design our ever smaller and thinner portable products also must consider the energy capacity and safety requirements in addition to the size requirements dictated by battery technology.

Related Articles

- The Future Of Li-ion Batteries

- How To Build A Better Battery

- Understanding The Factors In The Lithium-Battery Equation

The Growth Of The Li-Ion Battery

Li-ion battery technology really got portable electronics off the ground. It has much better energy density than previous battery technologies like nickel cadmium (NiCd) and nickel metal hydride (NiMH), especially when considering joules of energy per kilogram. Lithium isn’t the most stable element, though, so many new safety concerns arose with Li-ion’s introduction. The use of more sophisticated protection circuits has addressed these concerns.

This file type includes high resolution graphics and schematics when applicable.

Li-ion 18650 cells are common in laptops. Shaped like cylinders, they are 18 mm in diameter by 65 mm long. A typical notebook computer battery pack comprises an average of about four to approximately six 18650 cells to allow it to operate for several hours between charges.

About 10 years ago, lithium-polymer (LiP) cells made their debut in the consumer market. Because of their thin, rectangular, customizable pouch-like shape, LiP packs were attractive to designers looking for space savings, especially in ultra-slim notebooks, smartphones, and tablets. Today, LiP cells are used in these applications as well as in the latest large-screen smartphones, also known as phablets.

More recently, the PC market is trending toward slimmer notebook and tablet form factors combined with high-end processors, which must run complex programs in PC mode while still providing the “instant on” capability of tablet mode. All of these trends in consumer devices have driven the demand for larger, higher-capacity LiP cells with higher discharge currents, which in turn require higher current ratings in the battery protection devices used in these applications.

Battery Protection Challenges

Li-battery packs are particularly sensitive to faults caused by external shorts, runaway charging conditions, and abusive overcharging, which can cause potentially damaging overcurrent and overtemperature conditions. Moreover, organizations such as UL, IEC, and IEEE have enforced safety regulations and established test requirements for Li-ion and LiP packs to demonstrate their resilience to both short-circuit and overcharge events.

Component manufacturers are driven by the same trends of miniaturization and slimmer form factors that affect the portable consumer market on the whole. For example, circuit protection components must help battery pack designers address their need to design safe and reliable products that also conform to small form-factor requirements.

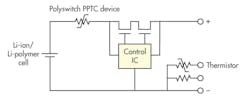

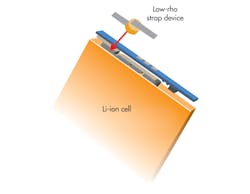

To illustrate how circuit protection products address these needs, “strap” and “disc” shaped resettable polymeric positive temperature coefficient (PPTC) devices can be used for Li-ion battery pack circuit protection while saving space (Fig. 1). A PPTC “strap” device comes in a flat, tab-like form factor that can be incorporated into various battery packs comprising cylindrical, prismatic, or LiP cells. It also can be applied to specific battery chemistries or usage profiles (Fig. 2).

A PPTC “disc” device is a bare disc made of PTC material that can be placed in a Li-ion 18650 cylindrical cell header to help protect cells during shipping and handling prior to assembly in packs. The disc device also provides protection for AA and AAA sized, non-rechargeable lithium cells that are sold individually for consumer use (Fig. 3).

Additionally, in response for the growing use of high-capacity LiP cells, an MHP-TA thermal cut-off (TCO) protection device combines a bi-metallic circuit breaker with a PPTC. The MHP-TA device offers a 9-V dc rating and a higher current rating than typical battery strap devices to meet the battery safety requirements of higher-capacity LiP and prismatic batteries (Fig. 4).

Conclusion

The Li-ion cell is now, by far, the most widely used battery technology in mobile devices. Other advanced technologies are rapidly being developed to accommodate the skyrocketing portable electronics market. According to a report by the research company Navigant, revenue generated by the sales of all advanced batteries for portable power applications will top $7.1 billion in 2013 and grow to over $12.4 billion by 2023.

Clearly, today’s Li-ion battery technology is driven by consumer demands for applications that have more computing power and come in thinner, smaller packages. In response, design engineers and components manufacturers must continue to find to find creative solutions that conform to these requirements.

About the Author

Barry Brents

Field Application Engineering Manager

Barry Brents is a field application engineering manager with TE Circuit Protection, a business unit of TE Connectivity. A member of IEEE and a former U.S. Navy nuclear submarine officer, he has been involved in the power and communications industries since 1989. He received his BSEE from Texas Tech University. He can be reached at [email protected].