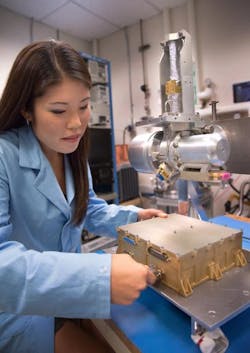

To maximize a satellite sensor’s sensitivity, it must be chilled using cryogenic refrigerators known as cryocoolers. NASA’s Orbiting Carbon Observatory-2 (OCO-2), launched in July 2014, used a high-efficiency cryocooler (HEC) developed by Northrop Grumman to perform that task. It successfully cooled the satellite’s infrared sensors to -244° F.

The pulse-tube cryocooler can cool instruments, sensors, and optics to temperatures ranging from -456° F to 80° F. Four sizes of flexure-bearing compressors and passive pulse tube cold heads make it all possible by promising longevity without performance degradation. The cold heads are customizable according to payload, For instance, they can be optimized for temperature and load, swapped out for coaxial cold heads, or adjusted to both reconfigurations.

OCO-2, NASA’s first dedicated remote-sensing satellite for studying atmospheric carbon dioxide near the Earth’s surface, started up as expected during a test run in August, and the sensors were found to be cooled to the required temperature. NASA’s Jet Propulsion Laboratory (JPL) in Pasadena, Calif., manages the satellite’s sensor instrument and conducted the cryocoolers’ characterization tests. Integration and/or testing of 20 other HEC-equipped spacecraft instruments is currently underway.