Are Consumers Really Ready for EVs?

Members can download this article in PDF format.

Electrical vehicles (EVs) and hybrids have been with us for over a decade now. And while annual sales have continued to grow, the total number of vehicles sold is small compared to overall vehicle sales. There are multiple valid reasons why consumers reject EV as a transportation choice. Most of them are well-known.

Today automakers and the parts suppliers are beginning to address these issues. For example, a major effort is underway among semiconductor companies to help automakers improve powertrain integration that should make EVs more attractive.

Sponsored Resources:

- A High-Performance, Integrated Powertrain Solution: The Key to EV Adoption

- Achieving High Efficiency and Enabling Integration in EV Powertrain Subsystems Using C2000™ Real-Time MCUs

- Carmakers charge ahead with electric vehicle powertrain integration

Consumer Issues

Consumers are avoiding EVs for two main reasons: range anxiety and high cost. Up to now, EVs were limited in the distance they can travel on a full battery charge. The typical internal combustion engine (ICE) can easily travel for 300 to 400 miles on a tank of gas. EVs have been limited to about 200 miles maximum with a full charge. The fear of running out of electricity creates excessive angst that most consumers wish to avoid, and a severe shortage of charging stations only exacerbates the problem. But conditions will eventually improve.

Another factor is the high cost of an EV. Today, on average, a typical EV costs $12,000 or more for automakers to produce versus a comparable ICE vehicle. While high battery cost is a major factor, other equipment also keeps prices high.

A major chunk of the cost for a modern EV is attributed to the powertrain. A significant breakthrough can be made by redesigning the powertrain to provide not only lower costs, but also help solve the other issues that afflict EVs. Powertrain integration is the solution.

The Powertrain

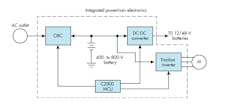

The EV powertrain consists of the high-voltage lithium-ion battery, its onboard battery charger (OBC), the main dc-dc converter, the traction inverter, and the main vehicle drive motor. In today’s EVs, these components are separate units that take up excessive space and must be interconnected with cabling.

The goal of powertrain integration is to redesign this system and package most of it into a single smaller unit while improving its efficacy. The result will be lower cost, smaller size, less weight, minimal heavy cabling, improved cooling, and significantly increased overall efficiency.

The figure shows a simplified diagram of a typical powertrain. The battery is typically a 400-V unit, but newer vehicles will use batteries with voltages to 800 V. The OBC lets you plug into a convenient outlet to recharge. The dc-dc converter translates the high voltage down to 12 and 48 V dc to charge the batteries that operate lights, power accessories, and other low-voltage equipment. The traction inverter converts the battery voltage into the three-phase ac that operates the main drive motor (M). A powerful MCU like the C2000 can monitor and control all of the integrated units. Redesigning and repackaging all or most of this into a single black box offers many opportunities to reduce costs and boost efficiency.

Improved Semiconductor Devices Make It Possible

The core components of these main drive-chain circuits are the power MOSFETs and IGBTs. Available silicon devices are being used to implement these circuits now, but that’s changing.

Wide-bandgap semiconductor FETs made with silicon carbide (SiC) or gallium nitride (GaN) are currently readily available. These devices offer the necessary benefits of higher junction temperature operation, high-voltage tolerance, high-current handling, higher switching speeds, and overall greater efficiency. Though costs remain high, prices are decreasing as volume rises.

Another semiconductor solution involves isolated gate-driver ICs to operate the power switches. These drivers translate the pulse-width-modulated (PWM) signals from the controllers into the pulses that turn the power devices on and off. In addition, the gate drivers provide the galvanic isolation required to separate the main functional circuits. The dc is isolated, but data signals are exchanged by way of capacitive isolators.

Addressing the Controller Need

In current EVs, all of this circuitry and equipment is controlled by multiple MCUs. Significant reductions in cost and complexity, as well as improved reliability, can be achieved by using a single fast, powerful, real-time MCU—assuming such a device is available.

One example is Texas Instruments’ C2000 MCU. It offers ultra-low latency and the higher switching speeds (1 to 2 MHz) of power circuits that make it possible to use smaller inductors and capacitors, thereby reducing cost, weight, and size. Real-time sensing and control and the higher speeds also permit designers to build and use higher-speed traction motors that can exceed the current approximate upper speed limit of 10K RPM to as high as 20K RPM. Such motors are smaller and offer improved vehicle performance.

The C2000 series MCUs are available in a significant range of variants with features and performance to fit most situations. And some versions include on-chip analog circuitry, such as comparators and DACs, further reducing size and cost.

Summing Up

EV sales will ultimately increase in the future simply due to the government mandates to reduce the emissions of ICE vehicles. The growth may not achieve some of the seemingly optimistic market predictions. One estimate is that the number of EVs will increase by 30% by 2025. Another shows sales growth of 20% to 25% per year is expected over the years up to 2030. If consumer range anxiety and high cost can be addressed, these results may come to fruition.

Nonetheless, the electronics to integrate the powertrain are now available. This will go a long way toward improving the efficiency of EVs and reduce their cost.

Sponsored Resources:

About the Author

Lou Frenzel

Technical Contributing Editor

Lou Frenzel is a Contributing Technology Editor for Electronic Design Magazine where he writes articles and the blog Communique and other online material on the wireless, networking, and communications sectors. Lou interviews executives and engineers, attends conferences, and researches multiple areas. Lou has been writing in some capacity for ED since 2000.

Lou has 25+ years experience in the electronics industry as an engineer and manager. He has held VP level positions with Heathkit, McGraw Hill, and has 9 years of college teaching experience. Lou holds a bachelor’s degree from the University of Houston and a master’s degree from the University of Maryland. He is author of 28 books on computer and electronic subjects and lives in Bulverde, TX with his wife Joan. His website is www.loufrenzel.com.