Upgrade Optoisolation Devices with Pin-to-Pin Semiconductor-Based Replacements

Members can download this article in PDF format.

Advances in high-voltage and high-data-rate circuits for applications in electric vehicles, telecommunications, aerospace, military, and more have taxed the limits of today’s photocoupling devices. To meet the demands of the next-generation galvanic photo isolation, the latest iteration of opto-emulators has taken up the challenge.

Traditionally, optoisolators, or optocoupler/photocouplers, are used to isolate signal circuits. However, traditional optocouplers are a mature technology and now bumping up against their technology ceiling—they have plateaued when it comes to performance. Therefore, another option for traditional optocouplers is needed. Texas Instruments offers a line of silicon-dioxide (SiO2)-based opto-emulators that can replace traditional air, epoxy, or silica-filled mold optocouplers insulation region.

Optocoupler Basics

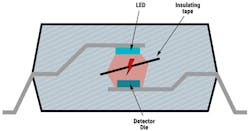

Optocouplers function by transmitting and receiving light signals. At one end is the light emitter and at the other end is the receiver. The isolation comes with the integration of an insulating barrier (as previously mentioned), which light passes through (Fig. 1).

Optocouplers and their mechanical cousin’s function is to deliver a non-physically conductive path for signal transfer. Their primary advantage is providing a significant margin of safety by physically isolating the signal path between the transmitter and receiver.

There’s no direct mechanical circuit connection between the Tx/Rx components. Rather, the signal is sent and received as light. This is particularly useful for numerous safety-conscious applications, such as high-voltage electric vehicles.

Traditional Optocoupler Limitations

Depending on the design, existing optocoupler technologies have some challenges. While they vary from material to material, optocouplers generally:

- Have limited bandwidth and poor high-frequency response.

- Require an external biasing voltage.

- Can’t handle high current.

- Tend to be limited in terms of long-distance signal transmission.

- Have limited temperature range, resulting in poor performance at temperature extremes,

- Exhibit degradation over their lifetime.

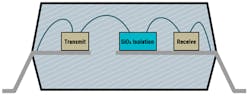

To address these shortcomings, TI’s ISOM8110, ISOM8711, and ISO87120 opto-emulators are next-generation optocouplers that use SiO2 for the isolation element. They’re referred to as opto-emulators because the traditional light-based isolation is replaced with non-light galvanic isolation (Fig. 2).

From the designer’s perspective, opto-emulators directly and seamlessly replace the most common optocoupler without requiring modifications to the circuit design. TI opto-emulators are exact pin-to-pin, drop-in replacements for such traditional optocouplers. They also offer an alternative to other existing isolation solutions, i.e., capacitive and magnetic components.

Opto-emulator Design 101

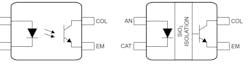

Opto-emulators deviate from optoisolator design when it comes to the input and output components. Rather than using an LED and phototransistor, opto-emulators employ diodes and transistors (Fig. 3).

The insulation barrier is constructed of SiO2. The use of silicon dioxide as an insulator is a novel approach because its technical parameters are much higher than other barrier technologies.

It takes advantage of very low-level thermal conductivity (typically 1.1 to 1.4W/m K) and a dielectric strength of 107 V/cm. By comparison, air has a thermal conductivity of 24.35 mW/m K (at 0°C) and a dielectric strength of 3 × 104 V/cm at room temperature. And SiO2’s parameters don’t vary across environmental variations, as does air and similar other standard materials used in photo-based optocouplers.

Because SiO2-based optocoupling devices are much more stable across environmental conditions (temperature, humidity, vibration, etc.), they’re well-suited for a much wider range of applications. Furthermore, they can handle much higher voltages than typical optocouplers.

Why Upgrade to Opto-emulators?

SiO2-based opto-emulators have a number of advantages over traditional optocouplers. Besides being footprint identical, they offer:

- A dielectric strength of ~500 VRMS/µm. This is up to 500X the dielectric strength of air, 30X that of epoxies, and 10X that of silica-filled mold compounds.

- Lower power consumption. Since optocouplers don’t degrade with age, there’s no need to design in additional compensation for aging over time. This can save up to 80% of the total power budget.

- Improved common-mode transient immunity (CMTI). For example, the ISOM8710 has a minimum CMTI of 125 kV/µs versus 15 kV/µs for light-based devices. This widens the application base for designs where common-mode (CM) or high ringing noise is a present.

- A stable and tight current transfer ratio (CTR). TI opto-emulators, such as the ISOM8110, come standard with a variety of tight CTR ranges that are stable over the full temperature specification range.

- Fast data rates for high-speed applications. The ISOM8710 supports 25 Mb/s, over twice the highest data rate of typical optocouplers.

- Bandwidth. A bandwidth of 680 kHz is standard. This enables the reduction of mandatory secondary components (inductor, capacitor, and transformer). It also offers an improved transient response for secondary-side regulated flyback converters, thereby lowering overall system cost, especially in high-switching-frequency gallium-nitride designs.

- Wide temperature range. TI opto-emulators support a temperature range from –55 to +125°C. Typical optocouplers have a range of 0 to +85°C.

- Reliable isolation. Opto-emulators offer enhanced high-voltage capabilities, making them suitable for demanding, hi-rel applications that standard optocoupler specifications can’t meet. The SiO2 insulating barrier provides 500 V/µm of isolation. This is significantly stronger than the air (1 V/µm) used in many optocouplers on the market.

In addition, automotive-qualified devices will be available in 2024.

Summing It Up

SiO2 opto-emulators are becoming a go-to solution for both existing and new applications, meeting the demanding specifications that stretch beyond traditional optocouplers. Their pin-compatible footprint, coupled with the ability to handle high voltages, temperatures, and other improved performance metrics, makes them an exact replacement for optocouplers.