What you'll learn:

- What is a digital twin?

- Digitally modeling a power plant with a digital twin.

- Omniverse-based digital twins for predictive plant maintenance.

Digital twins have the potential to play a major role in power electronics by speeding up prototyping, optimizing designs for higher power density, and enabling preventative maintenance for higher reliability.

A digital twin is a digital replica of a machine, device, or any other physical system, and it uses vast amounts of data to track its characteristics, properties, conditions, and behaviors. Central to any digital twin is a high-fidelity, interactive model running in real-time. The model is constantly updated based on feedback from multiple sensors in the system, while the data can also be used to provide analytical and statistical insights.

Utilizing the digital twin to study a physical object was introduced in 1991, in the publication Mirror Worlds, by David Gelernter. Michael Grieves (on faculty at the University of Michigan in 1991) is regarded as the first to apply the concept to industrial machinery and other assets in the manufacturing industry, in 2002, and he proposed the concept of digital-twin software. NASA’s John Vickers is credited with creating the term, digital twin, in 2010.

Bringing digital twins down to the level of power electronics is a relatively novel concept, though. For instance, researchers at the Fraunhofer Institute for Integrated Systems and Device Technology designed a digital twin of a high-power electric aircraft motor. The outer-rotor permanent-magnet synchronous motor is coupled with interleaved multilevel inverters based on silicon-carbide (SiC) MOSFETs, allowing for the use of fast switching frequencies based on pulse-width modulation (PWM) and a DC link voltage of 1,500 V.

>>Download the PDF of this article

It will be a while before digital twins transform the power electronics industry. But they’re already making a difference in large, highly complex, and capital-intensive engineering projects such as power plants.

Digital Twins: Using Data to Digitally Model a Power Plant

According to the Energy Information Administration (EIA), global electricity consumption will increase by 50% between now and 2050, driving up the scale and complexity of today’s power plants. As a result, future power plants will need digital-twin architectures so that they will be able to reach a high level of reliability, availability, and maintainability at a reasonable cost.

A digital twin of a hydropower plant, for instance, needs to use the enormous amount of data produced by the power plant as well as what the utility companies can understand about the ebbs and flows in the amount of electricity being distributed to the grid. Along with the proliferation of big data and AI, digital twins are becoming one of the core driving forces that will promote digital transformation within the power industry.

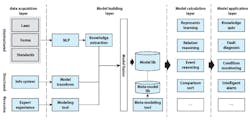

It will not be long before engineers can build a digital power plant that mirrors the operation of its physical counterpart in all of the ways that matter. They will be able to use the digital twin to make sense of the massive amounts of data flooding out of the electrical components. The figure illustrates the construction of a digital twin of a hydropower plant.

Let’s look at each major section in the figure:

Data acquisition layer: This is responsible for analyzing, acquiring, and storing unstructured and structured data. The format of the data source will include the database and other files, including JSON, EXCEL, TXT, and XML, among others. Engineers and other experts in the construction and operation of power plants can also start feeding in what they know here to help build the domain models.

Model building layer: This layer is the foundational functional layer of the digital twin model and application architecture. It serves as a sort of meta-model, which is the mechanism that’s used to construct the digital-twin model. This layer can include modules for:

- Natural language processing

- Knowledge extraction

- Model conversion

- Modeling tools

- Model fusion

- Model library

Model calculation/computing layer: The model calculation and computing layer is responsible for integrating general algorithm models that are used to impart a wide range of capabilities to the model application layer above it. These include:

- Representation learning

- Attribute reasoning

- Relation reasoning

- Event reasoning

- Comparison and sorting

Model application layer: This is where electric utilities and power generators can build applications that enable everything from condition monitoring and intelligent alarm to fault diagnosis and risk management.

By carefully assembling all of these components, engineers can create a digital twin of the power plant, simulating the operations taking place in the physical world, and continuously update it over time.

A Real-World Example of a Virtual-World Power Plant

This isn’t just a theoretical concept. Siemens Energy, one of the largest suppliers of power-plant technology, uses digital twins based on NVIDIA’s Omniverse to enable predictive plant maintenance. Omniverse is a real-time graphics collaboration platform utilized by companies to build digital twins that will design, operate, simulate, and optimize their products along with their production facilities. These digital twins are leading testing grounds for physical AI that will power autonomous systems.

Siemens builds and services “combined cycle” power plants, which include large gas turbines and steam turbines. These power plants recover the exhaust heat from the former to create steam used to drive the latter, improving the thermodynamic efficiency of the power plant by over 60%, said Siemens. But in parts of the heat recovery steam generator (HRSG), a mixture of steam and water can cause corrosion that may impact the lifetime of the system.

Siemens is building digital twins based on NVIDIA technology to reduce how frequently the power plant must be shut down for maintenance. The real-time data from sensors strapped to the turbines and other power generators, ranging from water temperature, pressure, and pH to turbine power and temperature, is processed to figure out the pressure, temperature, and velocity of both water and steam in the system.

These metrics are fed into a physics-focused AI model to accurately recreate how steam and water flow through the pipes in real-time. Then, Siemens feeds the flow conditions in the pipes into a digital twin based on Omniverse, which helps it understand and predict the effects of corrosion in real-time.

It will take some time before engineers can build digital twins of everything from EV traction inverters to DC-DC converters in data centers. The challenge is capturing all of the nonlinearities and fast switching behaviors of power electronics and then feeding the electrical, thermal, and electrothermal aspects of the power system into the digital twin. No one said it would be easy, but power engineers have more tools than ever to help make it happen.

References:

1. “Digital Twins for Modern Power Electronics,” Hao Bai, Johannes Kuprat, Caio Osório, Chen Liu, Marco Liserre, and Fei Gao, September 2024, IEEE.

2. “Digital Twin in Energy Industry: Proposed robust digital twin for power plant and other complex capital-intensive large engineering systems,” Ahmad K. Sleiti, Jayanta S. Kapat, Ladislav Vesely, Science Direct, Elsevier Energy reports, pp. 3704-3726, November 2022.

3. “Digital Twin for a 10 MW Electrical Drive System for Future Electric Aircraft Applications,” Xinjun Liu, Drives and Mechatronics, Christian Bentheimer, Florian Hilpert, Aerospace Electronics, Maximilian Hofmann, Drives and Mechatronics, Bernd Eckardt Vehicle Electronics, Martin Maerz, Fraunhofer Institute for Integrated Systems and Device Technology IISB, 2021 11th International Electric Drives Production Conference (EDPC), IEEE 2021.

4. “Applications of Digital Twin System in a Smart City System with Multi-Energy,” Qiang Lu, Intel Corporation; Huaiguang Jiang, National Renewable Energy Laboratory; Sisi Chen, Lambda School; Yi Gu, Baidu Online Network Technology (Beijing) Company Ltd.; Tianlu Gao, Jun Zhang, Wuhan University; 2021 IEEE.

5. “Construction and Application of Digital Twin Model of Hydropower Plant Based on Data-driven,” Zengtao Zhao, Dinglin Li, Jun She, Hao Zhang, Yupeng Zhou, CSG Power Generation Company, 2021 3rd International Workshop on Artificial Intelligence and Education (WAIE), 2021 3rd International Workshop on Artificial Intelligence and Education (WAIE), IEEE 2021.

6. “Siemens Energy Taps NVIDIA to Develop Industrial Digital Twin of Power Plant in Omniverse,” Richard Kerris, NVIDIA, November 15, 2021.