Why You Can and Should Build Rodent Resistance into Vehicle Systems

What you'll learn:

- How much of a problem are rodents for vehicle wiring?

- How can improved physical protection ward off rodents?

- How can enclosure design thwart rodents?

An “urban myth” persists that some cars, usually Japanese cars, in the popularly repeated tales, are prone to having their wiring damaged because the insulation is made from a soy derivative and is, therefore, particularly tasty for hungry rodents. Indeed, in Heber, et al. v. Toyota Motor Sales USA Inc. et al., Case No. 8:16-cv-01525, in the U.S. District Court for the Central District of California, 21 plaintiffs claimed that it was Toyota’s adoption of soy components in wiring that led to their cars being damaged by rodents.

The story is correct in that some types of electrical insulation incorporate soy derivatives. However, a rigorous study, “Assessing Rodent Gnawing of Elastomers Containing Soybean Oil Derivatives,” found no difference between these kinds of wiring and other polymer clad products in terms of their attractiveness to creatures. It concluded: “The inclusion of soybean oil or its derivatives in common elastomers did not affect rodent gnawing.”

How Much of a Problem are Rodents for Vehicle Wiring?

Nonetheless, what’s still true is that rodents and other living things can be a big problem for vehicle electrical systems. That’s either because creatures and/or their droppings, nesting material, or food end up where they don’t belong, or because said creatures actually chew into wiring and other electrical components, typically to keep the growth of their teeth under control. It’s a big problem that represents a significant cost to insurance companies offering comprehensive policies.

Indeed, recently, a Toyota Prius owner near Washington, D.C., faced with an escalating series of unexplained failures, including erratic brake activations, alarms, starting problems, dash lighting, and function failures, none of which service people seemed able to cure, finally noticed some telltale signs of mice that he reported to his insurance company. Their reaction was one of resigned familiarity.

>>Download the PDF of this article

After a brief look at the car, an adjuster made the determination that rodent wiring damage was the likely culprit. They “totaled” it and wrote him a check for the value of the vehicle.

For designers, this adds another wrinkle of complexity. When planning the wiring of a vehicle, key steps include:

- Creating a detailed electrical schematic.

- Meticulously laying out wire paths to minimize length and separate power levels.

- Selecting appropriate connectors and wire gauges based on current requirements.

- Considering routing for accessibility and protection from heat/abrasion.

- Utilizing 3D design software to visualize the harness layout.

- Incorporating features like strain relief and cable ties to ensure durability.

And during this process, they must adhere to industry standards and consider factors like environmental conditions and future maintenance needs. Now, add the challenge of rodent proofing everything without causing new problems like excessive heat build-up.

A starting point, of course, is automotive electrical insulation, which is typically made from polyvinyl chloride (PVC) or cross-linked polyethylene (XLPE). Both materials offer good resistance to high temperatures, chemicals, abrasion, moisture, and are at least somewhat resistant to rodent assaults.

Improving rodent-resistance is tricky because of the need to withstand the high temperatures generated by the many automotive systems without melting or degrading, let alone running up against space limitations.

Wiring also needs to resist exposure to oils, grease, acids, and other chemicals commonly found in a vehicle. It should be durable enough to withstand rubbing against other components in the engine bay while also resisting moisture in areas exposed to water or humidity.

How Can Improved Physical Protection Ward Off Rodents?

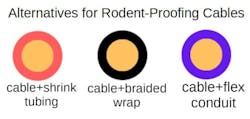

An option for designers is to add physical shielding to wiring and wiring harnesses. This starts with the familiar heat-shrink tubing, available from many manufacturers, which offers an additional polymer layer and can help neaten and organize wire runs. It does have some complexity and steps in creating harnesses.

Other similar products, such as those offered by Zippertubing, don’t require that wires be preinserted in the tubing. It can offer additional protection against intrusion by dust and liquids as well as EMI shielding.

Going a step further, Techflex Flexo RRN offers a wire and hose braided conduit that has a foul-tasting coating that discourages rodents from chewing on wires and cables. According to the company, during in-house testing, “rodents completely avoided new Flexo Rodent Resistant even when stuffed with food.” Available materials include polymers, aramids, and metals.

And, while not explicitly aimed at rodent threats, the flexible conduit products such as those from ABB’s Harnessflex team are designed to carry wiring and integrate with commonly used electrical connectors, cable management solutions, cable glands, vibration friendly profile conduit, and fittings.

How Can Enclosure Design Thwart Rodents?

While wire and cable vulnerabilities are the most obvious and widespread risk relative to rodents, enclosures and, as much as possible, the whole vehicle should be made unfriendly and resistant to rodents. Sealed enclosures are most effective when the surfaces are smooth and made of metals, fiberglass, and high-impact plastic.

Gaskets and sealants should block all gaps in the enclosure, and appropriate grommets and sealants should make tight seals where cables or other components enter the enclosure. Some sources also suggest that rounded corners or edges can make it harder for rodents to loiter on an enclosure, maneuver, or gain enough leverage to push into openings.

References

“Assessing Rodent Gnawing of Elastomers Containing Soybean Oil Derivatives”

“Effectiveness of rodent-proof cables in resisting damage caused by black rats Rattus rattus”