Download this article in PDF format.

Kinetic energy harvesting offers a universal way to harvest energy in engine compartments, simply due to the fact that vibration energy is always present in varying amplitudes. By using different conversion principles and an appropriate microelectronics system, this energy can be efficiently converted into electrical energy. However, the performance of energy harvesters greatly depends on their ability to adapt to the environmental source.

An automotive aim is to collect the energy generated by shock absorbers and reuse it to recharge the batteries. Recent advances in the development of ultra-low-power microcontrollers have enabled devices that offer unparalleled levels of integration over the power required for operation. In this way, power can be more effectively delivered if it accumulates from the mechanical, thermal, and electromagnetic energy available in the local environment. Collecting sources such as heat, light, sound, and vibrations could significantly impact economic and environmental factors, reducing costs and spawning new sensor technologies for the automotive industry.

Energy-Harvesting Transducers

Mechanical energy is present in nature in the form of various sources, such as vibrating structures or fluid that flows along those structures. Wherever there’s a mass, there’s also great potential for energy-harvesting applications.

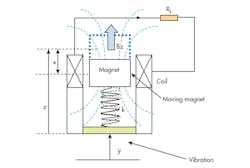

1. In this block diagram of an electromagnetic-vibrational transducer, RL is the load and Bz is the direction of the magnetic field. Electromagnetic-vibrator transducers are able to convert vibration energy into electrical energy from 40 to 100 mW.

Transducers of various types carry out the collection of energy and convert it into electricity. The electromagnetic-vibrational transducers are based on Faraday's law. The motion of a coil, through a constant magnetic field perpendicular to it, generates an electric field capable of circulating an electric current in a load connected to the heads of the coil (Fig. 1). The piezoelectric transducer offers higher-power-density collection, thanks to the advantages offered by the microelectromechanical-systems (MEMS) implementation.

The maximum power that’s supplied to energy-harvesting devices depends on the frequency and acceleration of the vibrating system as well as the size of the device. Piezoelectric accelerometers are used most often, due to their high dynamics, small size, and immunity to noise factors. The reversibility of the effect is one of the piezoelectric’s main features—namely, the generation of electrical energy by means of a mechanical stress and vice versa.

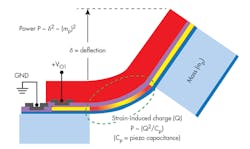

2. The formula at the top left of this piezoelectric-transducer block diagram means the proportionality of the power obtained from the transducer with the deformation amplitude (δ) and mass (mp) of the material. Circumscribed by the dotted ellipse, it’s possible to observe the area under stress (strain) caused by the deformation of the material. This results in the formation of electric charges (Q) and electric energy (P).

Figure 2 shows the operating principle of the piezoelectric transducer. The peculiar characteristics of piezoelectric materials make electromechanical transduction possible due to deformation of the material. Virtually, they generate electrical signals in response to an external mechanical stress.

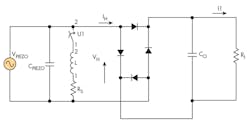

Energy-harvesting systems with piezoelectric transduction have a highly reactive output impedance. Since a typical piezoelectric produces few milliwatts, IC system designers have turned to a number of nonlinear approaches to improve power without major overhead costs. A typical approach is called a synchronous switched harvesting on inductor (SSHI), which involves reversing charge polarity on piezoelectric material twice per cycle (Fig. 3).

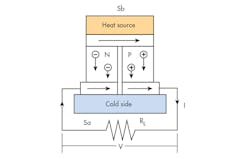

3. A potential difference is generated to the extremities of the junction surface in this illustration of the Seebeck effect, resulting in an electric current that’s proportional to the temperature differential of the two surfaces (hot and cold).

Thermoelectric transducers convert thermal energy into electricity by means of the "Seebeck effect" phenomenon. The thermal energy is primarily available in the industrial sector (machinery, pipes, and vehicles), in buildings, and in the human body, where there’s always a thermal gradient (Fig. 4).

4. This synchronous switched harvesting on inductor (SSHI) circuit uses a rectifier for the piezoelectric transducer.

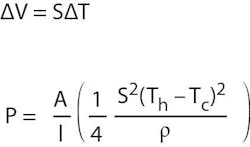

When two conductors are at different temperatures, a potential difference is produced between the two ends. The voltage (V) generated between the two junctions depends on the material and the temperature through the first equation below as a function of the Seebeck coefficient (S). The second equation represents maximum power collection.

A represents the section of the material, ρ the resistivity of the material, and l the length of the sensor; T indicates the temperatures of the hot (h) and cold (c) surface.

The direct conversion of solar energy into electricity, realized with the photovoltaic cell, uses the physical phenomenon of the interaction of light radiation with valence electrons in semiconductor materials, called the photovoltaic effect.

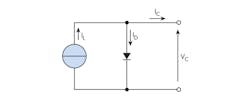

In the single cell, the photocurrent generation coexists with the mechanisms that regulate the normal flow of current in a p–n junction to vary the voltage at its ends. The photocurrent has an intensity that depends on many factors: radiation, angle of incidence, temperature, and types of semiconductor materials (Fig. 5).

5. In this equivalent circuit of a photovoltaic cell, the typical output voltage of a cell is about of 0.5 to 0.6 V. Typical values of photocurrent for a cell are approximately 30 mA/cm2.

Power-Management Circuit and Storage

Designing a power-management system for a device that collects energy from different environmental sources can be rather difficult. These sources, from solar to vibrational, passing through that heat, are small amounts of energy that vary unpredictably. This creates a significant challenge for a power-management system that needs to work efficiently and deliver a steady output.

The piezoelectric transducers operate with an output voltage of some millivolts (1 to 10 mV), which changes in accordance with the environmental conditions and materials used. Different power management circuits, such as a boost converter, are used to limit the oscillations.

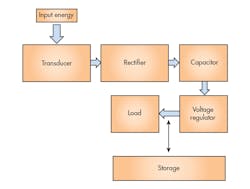

6. Shown is a general energy-harvesting system, in which a rectifier and capacitor are used to convert ac energy into dc. A voltage regulator helps to adapt the voltage level to the requirements of the powered devices.

A buck/boost converter is an architecture suitable for harvesting energy for various artificial/environmental sources, from motion or vibration through a piezoelectric transducer passing through RF energy. In an energy-harvesting system, the output voltage isn’t constant in time (Fig. 6).

It’s very important to keep the energy constant over time, just as in photovoltaic devices. The goal is to provide a way to compute the initial storage element charge before commissioning energy that’s needed to supply the load. Supercapacitors, also known as ultra-capacitors or electrochemical capacitors, have enabled an alternative mode for energy-storage technologies (Fig. 7).

7. A supercapacitor is characterized by two electrodes and an ion-permeable separator placed between the electrodes.

Collecting energy from the environment is a way to prolong battery life in various electronic designs. Instead of having to recharge a small battery every 12 hours, small amounts of energy when the system is in sleep mode can provide more power and prolong the lifetime of the charge. Energy harvesting will also grow in automotive applications and mobile communication with cellular phones through RF energy harvesting.

In the automotive sector, energy harvesting has a potential role to play in two broad areas. The first is related to small wireless sensor networks for managing some parameter of road safety. The second is related to the charging of the batteries in distributed energy-storage systems for electric and hybrid vehicles. With hybrid and electric cars, the trend toward energy harvesting by thermal and vibration sources represents a new way for the free energy in the automotive systems.