Download this article in PDF format.

This past January 9, 2017 marked the 10th anniversary of the debut of the iPhone, and suitably marked by a flurry of media comment. At TechInsights, we took a more considered approach to this milestone and looked at the technology evolution within the device. There’s certainly been plenty of that! With the iPhone 8’s introduction this week, tracking the phone’s evolution may give us a glimpse into Apple’s product-development strategy, and into what’s coming next.

1. A still taken from the official launch of the Apple iPhone.

To start, I took a look at the video of the launch (Fig. 1). Check out the video:

It was certainly a trip down memory lane; the hits shown on the music lists included Nellie Furtado and Alanis Morrissette. Today, the original iPhone and its competitors are museum pieces. Even so, with the iPhone, you can see the continuity in the design history. Steve Jobs did not have good things to say about the leading-edge phones of the time.

He described the iPhone as “a widescreen iPod with touch controls, a revolutionary mobile phone, and a breakthrough internet communications device.”

He made a big deal of the “large” (that’s not what we think now!) 3.5-in. screen, but it was really the software behind the touchscreen that defined the device, allowing multi-touch capability so that users could flip through lists and photos, zoom the display in and out, interfacing the screen with all of the background iPod and phone functions, and, of course, providing the text keyboard. The screen itself was relatively high resolution, at 160 ppi (pixels per inch), and there was a 2-Mpixel camera, about par for the time.

Apple also had ported its Safari browser into the device and beefed up the email capability, giving it a richer interface than any of the competition. As I remember it, most of the other features were already available in one or another of its contemporaries, but it was the combination of them that made the iPhone unique.

The add-in that impressed me most back then was the microelectromechanical-systems (MEMS) accelerometer, which enabled rotating the screen to view pictures and movies in landscape format; no-one else had done that. I think that was all Apple used the MEMS for at the launch, but it didn’t take long for the app developer community to expand on it. Very few phones incorporated MEMS at the time, but they were used for “shake & do” apps, nothing to do with the screen.

There were also ambient-light and proximity sensors to adjust screen brilliance and turn the touchscreen off when the phone was used as a phone—as was we described in TechInsights’ time-of-flight sensor blog—the latter did not work particularly well in this first iteration.

On the wireless side, it was definitely not a world phone, being introduced only on the Cingular/AT&T network. At launch, it didn’t even have FCC approval.

The Original

2. The original iPhone’s electronics broke down into two boards.

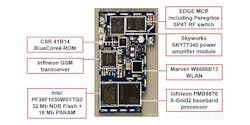

When the phone finally appeared at Chipworks, now TechInsights, in July 2007 (actual release was June 29), it of course didn’t stay in one piece for long. The electronics broke down into two boards (Fig. 2). Looking at the wireless board, we can see that we have a good sample of the industry suppliers of the day (Fig. 3).

3. Surveying the components reveals the different suppliers involved during that time.

Infineon has since sold its wireless division to Intel, and CSR has been absorbed by Qualcomm, but Skyworks is still a big player in the RF front-end. Unfortunately, we didn’t identify the make of the Apple-branded EDGE multichip package (MCP). The Peregrine switch inside that was noted because it used silicon-on-sapphire technology, not a first, but unusual. Peregrine is now part of Murata, and has developed its UltraCMOS process to be one of the larger users of RF-SOI wafers, even moving it to 300-mm wafers.

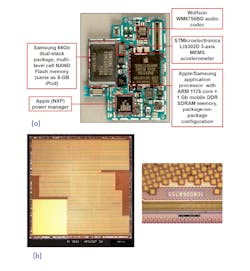

The other board had the apps processor + DRAM, flash memory, audio codec, power management, and MEMS (Fig. 4). There are also Linear Tech USB power-management and National Semiconductor Mobile Pixel Link interface chips that aren’t annotated in the image. The camera was made by Micron.

4. Shown is the second board’s components (a), and the Apple iPhone application processor die photo and die mark (b).

Again, we have industry evolution; Wolfson is now within Cirrus, Texas Instruments bought National, Micron’s camera division became Aptina, now in ON Semi, and NXP is being absorbed by Qualcomm (assuming regulatory approval).

Looking at that inventory, we can say that there were no individual leading-edge chips giving the iPhone its market edge, or outstanding performance as a phone—rather it was the integration of the innovative touchscreen, multiple applications, and sleek design.

In packaging terms, the iPhone followed the cell-phone trend, and was fairly replete with condensed packaging for the time: two MCPs (the Peregrine part and Intel memory), the dual-stacked Samsung NAND flash, and the Samsung app’s processor + SDRAM PoP (package on package). The Marvell and CSR chips were both flip-chip on board.

iPhone 4

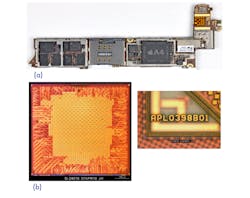

I could review all our analyses of the last 10 years, but that could be tedious, so let’s look at the iPhone 4 (Fig. 5). This was a bit of a turning point, since Apple moved away from single-sided PC boards to more compact, high-density double-sided boards. More significantly, they had started using the A series of apps processors, here coincidentally dubbed the A4, though it was first used in the iPad.

5. Here's a look at the iPhone 4's motherboard (a), and Apple A4 die and die mark (b).

It was also the first iPhone with a compass chip, plus a gyroscope and tri-axis accelerometer. The camera was upgraded to a video-capable 5-Mpixel unit (no selfie cam back then; that didn’t show up until the 5S). The wireless side was upgraded to cover both 3G CDMA and 2G GSM standards, but we still had the 3.5-in. screen.

iPhone 7 and 7 Plus

The iPhone 7 series is almost unrecognizable when compared with the original. The 7 models are 4G LTE world phones capable of working with over 40 wireless bands, and equipped with carrier aggregation to improve signal sensitivity. The screens are pressure-sensitive with “3D Touch.” The 7 has a 4.7-in., 326-ppi screen, and the 7 Plus has a 5.5-in., 401-ppi version.

When it comes to cameras, both have a 7-Mpixel selfie camera at the front; the iPhone 7’s main camera is a 12-Mpixel unit, and the Plus has dual 12-Mpixel wide-angle and telephoto cameras with f/1.8 and f/2.8 apertures (respectively), 2X optical zoom, and 10X digital zoom. As noted above, the selfie has a ST time-of-flight sensor that acts as proximity (and likely autofocus) monitor.

A fingerprint sensor was introduced in the 5S, which is now in its second generation. In addition to the motion and direction sensors, there are now barometric, temperature, and humidity sensors, as well as a heart-rate monitor, to enable all those apps that we download.

It currently features a 3.3 billion-transistor, 64-bit, quad-core A10 processor, built on TSMC 16-nm technology, with a 6-core GPU and 2 GB of DRAM (3 GB in the Plus, and up from 128 MB in that first model). Thanks to the advances that we’ve had in flash memory, as well as the demand for more and more data, the maximum memory has gone from 8 GB to 256 GB in the 10 years.

With the expanded wireless capability, the RF end of the board is a lot more complex, and in the North American versions, Intel has used its Infineon technology to get some design wins (Qualcomm fills these slots in other parts of the world). We again see Skyworks, but also Broadcom/Avago, TDK, and Qorvo.

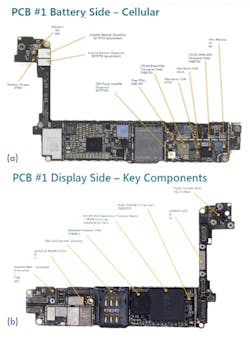

6. Many more components populate the iPhone 7 on the battery (a) and display (b) sides of the PCB.

In general, given the degree of integration that has happened in semiconductor logic, I would have expected that there might be fewer parts in a newer phone. However, because of the huge range of applications that our phones perform these days, there are actually a lot more chips on the board (Fig. 6).

In the first iPhone, we said that “there were no individual leading-edge chips giving the iPhone its market edge.” That’s definitely not the case now, and hasn’t been for several generations.

Pretty well every component in current iPhones is leading-edge or a custom design, from the RF front end through the power-management chips (there are now several of them), the cameras, the memory, and of course the A10 processor, built on the latest FinFET process (Fig. 7). The same applies to the chip packaging, with the first use of TSMC’s InFO technology for the A10, and many chip-scale flip-chips on-board.

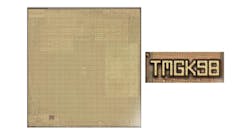

7. Shown is the Apple A10 die photo and die mark.

iPhone vs. iPhone 7 Manufacturing Cost Comparison

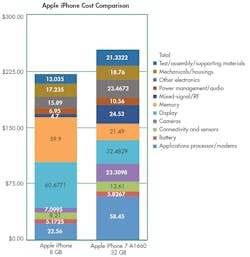

Ten years ago, the original iPhone launched at a cost of $599 for the 8-GB model. The 32-GB iPhone 7 sells for $649. Let’s look at how the manufacturing costs changed over time (Fig. 8).

In 2007, TechInsights estimated that the manufacturing cost of the original iPhone was $221.45. Our best estimates for the manufacturing costs of the iPhone 7 are $253.82, or $32.37 more expensive than the original version. Despite significant advances in performance and capabilities, Apple has managed to keep costs under control. Certain components within the phones have shot up in cost, while others have dropped significantly.

The original iPhone was equipped with an Apple-designed, Samsung-produced applications processor and an Infineon GSM/EDGE baseband processor. This combination cost an estimated $22.58. The iPhone 7, on the other hand, is equipped with an Apple A10 applications processor made by TSMC and a Qualcomm MDM9645 LTE baseband processor. This much more powerful combination of parts adds up to $58.45, or 2.6X the cost of the original. In this case, however, you get what you pay for—a quad-core, 2.34-GHz processor along with an LTE Advanced modem.

8. The chart compares costs between the original 8-GB iPhone and the 32-GB iPhone 7.

The next significant cost difference is seen in the area of connectivity and sensors. The original iPhone parts added up to $8.21, while the iPhone 7 parts total $13.61, or 1.6X the cost of the original. Both come equipped with Wi-Fi, Bluetooth, and an accelerometer. The iPhone 7 adds secure NFC, gyroscope, compass, barometric sensor, Touch ID, and ambient-light sensing.

The camera category saw a 3.3X jump in cost from $7.10 to $23.31. While the original iPhone came with a 2-Mpixel camera, the iPhone 7 bests that with a 7-Mpixel front camera, a 12-Mpixel rear camera, and an LED Flash.

With these increases, how could Apple save money? One area where savings were realized is in the display/touchscreen module. The original 3.5-in. TFT display cost Apple $60.68 ten years ago. The 4.7-in. TFT in the iPhone 7, which is a carryover from the iPhone 6 and 6S, costs $32.48 in today’s market. Ten years is a long time to drive down manufacturing costs of these parts. A 3.5-in. display/touchscreen module would likely cost between $10 and $15 today.

Another area where Apple saved cost is memory. Ten years ago, Apple equipped the iPhone with 8-GB (its higher tier) MLC NAND and 128-MB DDR SDRAM. The 8-GB NAND accounted for most of the $60 cost. Back then, most devices were lucky to come with 2-GB NAND. The iPhone 7 we analyzed comes equipped with 32-GB MLC NAND and 2-GB LPDDR4 SDRAM. In this model, the costs by type have essentially flipped, with the DDR4 making up about two-thirds of the $21.49 spent in this category.

We also see an explosion of costs in the mixed-signal/RF category. This category is mainly comprised of parts that make up the RF section (transceivers, power amplifiers, filters, RF switches, etc.). The original iPhone was only GSM/EDGE and had a category cost of $4.70. The iPhone 7 adds many HSPA and LTE bands to it, causing the cost to jump to $24.53. Here, greater functionality and complexity equals more cost.

Along the same lines, the power-management/audio category has become more complex on the iPhone 7, resulting in a cost jump from $6.95 in the iPhone to $10.56 in the iPhone 7.

We see a similar increase with other electronics. The iPhone had $15.89 in parts, while the iPhone 7 cost $23.47. In essence, the difference in the phones from a cost perspective comes down to more parts and functionality.

The mechanical costs are about on par with between the units, with the iPhone costing $17.24 and the iPhone 7 costing $18.76. Here, the difference comes down to manufacturing processes and finishes.

The test/assembly/supporting materials category costs increased from $13.04 to $21.33. Higher labor rates and assembly times, as well as significantly more parts, account for the increase.

Conclusion

Over the course of the last decade, Apple has done an excellent job of maintaining its business case for its iPhone line. From the first iPhone to the iPhone 7, Apple controlled manufacturing costs through incremental upgrades over time as opposed to quantum leaps. The company has refrained from using certain technologies (i.e., AMOLED displays and their cost premium over TFTs) so as not to compress its margins or increase the selling price beyond where it already sits. Apple also managed to virtually maintain its street price, increasing it only slightly with the iPhone 7.

With the introduction of the iPhone 8, TechInsights will soon have answers to what’s inside the new device. Will Apple continue to rely on leading edge designs or will they embrace new, but relatively unknown technology? Regardless, the evolutionary path of the iPhone in general makes me wonder, what will we see in another 10 years?