Engineers at Florida State University’s National MagLab set a new world record for a resistive magnet, eclipsing the previous one by about 8%—a sizable leap in magnet technology terms.

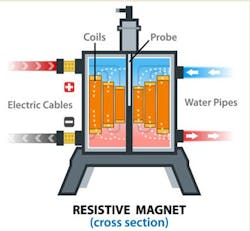

“Resistive magnets (Fig. 1) are the bread and butter of MagLab’s DC Field Facility, and the demand of scientists sometimes exceeds supply,” said MagLab Director Greg Boebinger. “With the Project 11 magnet, we asked our engineers to ‘turn it up a notch’ and see what they could accomplish. This new brute delivers and will enable scientists to make discoveries that lead to better materials and technologies and deepen our understanding of how our world works.”

The new instrument reaches 41.4 tesla (Fig. 2). It is the culmination of two-and-a-half intense years of design and development. In so doing, the lab reclaimed the record for the world’s strongest resistive magnet, which it had held for 19 years up until 2014.

The effort has been known in-house as Project 11. That extra oomph allowed the lab’s new magnet, fueled by 32 MW of DC power, to leapfrog over the previous record-holders: a 38.5-tesla resistive magnet in Hefei, China, and a 37.5-tesla resistive magnet in Nijmegen, the Netherlands.

The new 41.4-tesla magnet is easy for scientists to use and gives them flexibility to adjust the field and polarity during experiments. This new system will be made available to visiting scientists in the coming months, joining a fleet that features a pair of 35-tesla instruments that, until this week, had been the lab’s strongest resistive magnets.

Although the lab’s newest magnet works on the same principles as all resistive magnets, it is no run-of-the-mill machine. Lab engineers, drawing on years of experience designing and developing the facility’s other unique magnets, introduced improvements to maximize the electrical current density that helped catapult them to the new world record. At the same time, they kept costs down by repurposing parts from retired magnets.

“This larger magnet allows us to use 50% more coils,” said veteran magnet designer Jack Toth, who oversaw a team of dozens of engineers, technicians, and support staff on the project. “That enabled power to be distributed more efficiently within the magnet and reach a new record with the same materials.”

Magnet Power Sources

MagLab has four dc power supplies of 20 kA—700 V each. The Lab has essentially its own substation for the city utility across the street. Power comes into the building at ~12.47kV AC. In-house oil-cooled transformers that reduce the voltage to ~700 V. The power then goes upstairs to 24-pulse, water-cooled, thyristor-based rectifiers. Next, it passes through a passive filter (inductors and capacitors) and a water-cooled, transistor-based active filter.

Power goes through reversing switches, into air-cooled aluminum bus bars that run the length of the building with disconnect switches to each of 16 magnet cells. Cells have water-cooled flexible copper cables that are connected to the magnets.

There are two supply circuits for the magnet cooling water with a common return. There are five pumps—two on each circuit, plus one that is valved into either circuit. The magnets are cooled with deionized water with resistivity of 10 MΩ-cm. The magnet cooling water runs through a heat exchanger to a chilled water loop that has ~4Mgal of storage at ~6°C. The chilled water is maintained by chillers that dump their heat to a third loop that runs to cooling towers.

Most of the magnets run on two power supplies in parallel. The two highest field magnets require three power supplies and one requires only one power supply.

Hybrid Magnet

MagLab also has a premier magnet that is a hybrid configuration combining superconducting and resistive magnets. The resistive magnet is located in the bore of the superconducting magnet, where the magnetic field too high for traditional superconductors. By using this hybrid approach, higher fields can be attained than with superconducting magnets, and lower operating costs can be attained than with resistive magnets. The resistive magnet’s coils are copper sheet metal with cooling holes stamped in them; associated insulators have the same pattern. Coils and insulators are stacked to form a helical structure. When voltage is applied to the coil, current flows through it in a helical pattern, producing a high magnetic field at its center. This produces very high fields that consume considerable power.

This system provides the highest fields with a minimum use of electric power. An 11.5 tesla superconducting magnet is on the outside and a 34 tesla magnet is on the inside, producing 45 tesla in total. One of the operational problems of a hybrid magnet is that you have to keep the superconducting magnet cold, in this case about 1.5 K above absolute zero, while still running a huge power-generating magnet in the middle of it. The combination of these two is a difficult electrical and mechanical engineering problem because you have to prevent them from damaging each other or causing large voltages that could injure an operator.

Scientific Tests

Scientists use magnetic fields in two primary ways to affect the particles—either electrons, protons, or neutrons inside the material. Magnetic fields of each individual electron will line up with the magnetic field, which can cause a material that wasn’t a magnet to become one, or it can change the way it operates or reflects light. Also:

- If the particles have an electric charge, and are moving, the magnetic field actually bends its current around and forms a circular orbit field.

- If particles have their own magnetic field, they can line up those magnetic fields in the same way a compass lines up with the Earth's magnetic field.

For example, when excitons (electrons and holes) in a material begin to strongly interact with each other (condense), the material begins to behave like a so-called superfluid—a fluid with zero viscosity that flows without losing any kinetic energy. When stirred, a superfluid will continue to rotate indefinitely.

In one experiment, scientists first created a kind of sandwich: the bread consisted of two “slices” of graphene, a one-atom thick form of carbon that conducts better than copper, and the “filling” was a layer of hexagonal boron nitride (BN), an insulator.

They put this sandwich in a powerful magnet and an extremely cold environment. First, they observed excitons that were bound together across the BN layer in a special state called the quantum hall state that occurs in magnetic fields. In addition, the scientists observed the excitons condense into a special kind of superfluid known as a Bose-Einstein condensate (BEC).

An engineered geometry, the BEC can be tweaked with magnetic and electric fields. This opens up an exciting new way to study the interactions that govern the pairing of electrons and holes in an engineered geometry. This research result could fundamentally alter existing approaches to electronic design.

These observations were made at the MagLab independently by two different research teams, one from Harvard University and one from Columbia University.

Another experiment looked at materials that conduct electricity. Generally, materials are considered either conductors (like copper) or insulators (wood, for example). Some materials, however, don’t fall so neatly into one category or the other, and they tend to be of particular interest to scientists. Nickel disulfide (NiS2) is one such material. It is known as a Mott insulator: Even though its structure suggests that electrons should move through it to conduct electricity if a voltage is applied, it is in fact an insulator. Its electrons are stuck in place because of the way they interact with one another.

Scientists can sometimes change a material’s conductive/insulating state by changing its environment — changing the ambient temperature or pressure, for example, or introducing a magnetic field. When they put NiS2 under high pressure in a high magnetic field, electrons that had been in virtual gridlock are liberated: The material is converted from an insulator (think plastic) into a conductor (like a metal).

Of particular interest to the scientists was how those electrons moved. In conventional electricity, electrons move as individual particles. But in the NiS2, the electrons were influencing each other as they moved, advancing not as individuals, but as a system. Scientists call this behaviour “highly correlated.”

Scientists are especially interested in this kind of behavior because it’s exhibited by some high-temperature superconductors (HTS). HTS materials, which conduct electricity with perfect efficiency at relatively high temperatures, are of intense interest among physicists.

Some scientists speculate that understanding this complex state of matter holds the key to engineering HTS materials that work at higher temperatures. The higher that temperature, the closer we are to being able to use HTS materials for energy and other applications that could revolutionize the power industry.

In Magnetics, What is a Tesla?

Tesla is a unit of magnetic field that equals10,000 gauss (magnetic flux density). To put this into context, a strong refrigerator permanent magnet can be 100 gauss. Magnets in the MagLab range from 20 tesla up to 45 tesla for DC fields. Pulsed fields can go as high as100 tesla, and even higher. The energy required to produce magnetic field is proportional to the square of the magnetic field—e.g., to go from a 1 tesla to a 10 tesla magnet requires 100 times more energy.

About the Author

Sam Davis

Sam Davis was the editor-in-chief of Power Electronics Technology magazine and website that is now part of Electronic Design. He has 18 years experience in electronic engineering design and management, six years in public relations and 25 years as a trade press editor. He holds a BSEE from Case-Western Reserve University, and did graduate work at the same school and UCLA. Sam was the editor for PCIM, the predecessor to Power Electronics Technology, from 1984 to 2004. His engineering experience includes circuit and system design for Litton Systems, Bunker-Ramo, Rocketdyne, and Clevite Corporation.. Design tasks included analog circuits, display systems, power supplies, underwater ordnance systems, and test systems. He also served as a program manager for a Litton Systems Navy program.

Sam is the author of Computer Data Displays, a book published by Prentice-Hall in the U.S. and Japan in 1969. He is also a recipient of the Jesse Neal Award for trade press editorial excellence, and has one patent for naval ship construction that simplifies electronic system integration.

You can also check out his Power Electronics blog.