Cell phones that stream color video. Personal digital assistants (PDAs) with 16-bit color screens. Displays on numerous electronic devices, including cell phones, PDAs, automotive dashboards, and medical devices, now are in color and offer higher resolution and the capability to handle streaming video.

If industry analysts are correct, the mobile terminal market will double in size over the next five years. Look no farther than Japan and its advanced cell-phone network, DoCoMo, to see the future of mobile digital communications.

Flat-Panel Display Testing Trends

Traditional testing of flat-panel displays was rather straightforward because the displays were monochrome with relatively limited resolution. Today, mobile devices have color displays with much higher resolution.

This shift in technology has forced the testing methodology to change. In addition to performing high-resolution color testing, systems must be able to test displays in a specified amount of time to meet manufacturing throughput requirements.

Many manufacturers not only are interested in testing the display, but also other components of the end product. They need to perform audio tests, shock tests, RF tests, and noise-vibration-harshness (NVH) tests. They also want to add their own specialized tests in response to product evolution since tomorrow’s mobile devices will have different testing requirements than today’s models.

The Problem

Last year, Flextronics International, a global contract manufacturer, needed a vision solution to inspect displays on cell phones. Aware of such fast-approaching trends that would require displays to have high-resolution color and streaming video, the company wanted a display inspection solution that could be used on future products. Flextronics also wanted to develop in-house machine-vision expertise and not have to rely on outside suppliers.

On this particular project, the company was required to inspect two display panels on cell phones: one on the front displaying numbers, address books, etc. and a smaller screen on the back to display the caller identification number. In addition, protective tape was on each of the displays, adding another degree of difficulty to the imaging challenge.

In searching for a solution, Flextronics found most vendors offered complete turnkey systems. This was an expensive option and failed to meet a key criterion—to gain in-house imaging expertise. If testing needs changed, the company would have to contact the consultants to change the system, an expensive and time-consuming process.

A Better Solution

A new approach to testing displays was needed, one that included an easy-to-understand test executive, interactive configuration panels, the capability to use standard programming tools, and an open architecture. Due to the open nature of this new approach, test-system developers can specify best-of-class components.

The camera can be selected based on resolution and speed requirements; the lighting and optics can be chosen to ensure maximum contrast and resolution of the features being measured. These products in conjunction with an image-acquisition device, appropriate software, and a PC yield a complete testing system using components specifically tailored for testing flat-panel displays.

A PXI-based hardware approach to testing, leveraging the power of the PC and CompactPCI, enables users to add other measurement and automation functionality through plug-in cards. Not only can displays be inspected using image-acquisition PXI modules, but the capabilities of the display test platform can be extended by adding other PXI modules for functional testing.

For example, a digital I/O device to generate test signals might be used along with data acquisition hardware that measures tone and frequency response and performs other tests. System developers can expand the platform to include motion control for mechanical functional test of keypads. Using off-the-shelf measurement devices, users can easily integrate other tests into their system such as call processing, RF testing, streaming video, battery testing, and current draw.

Scalable software and tightly integrated driver software, such as NI-IMAQ and NI-DAQ, communicate with image-acquisition and measurement devices. Higher-level software tools such as LabVIEW, Visual Basic, C, or C++ with vision algorithms combine to form the actual display tests.

A Suite of Tests

When performing display inspection tasks, a number of key vision tests are used in nearly every situation. Software that offers several of these most popular tests prebuilt allows engineers to focus on the other parts of their job rather than spending time developing the tests.

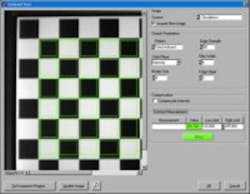

Since display tests must be configured to meet the inspection requirements of the unit under test, engineers need an easy-to-use interface to configure their tests. For that reason, an inspection test solution must have modifiable parameters.

Test setup involves setting parameters that govern the behavior of the test, selecting inspection regions, and defining tolerances to specify the acceptable range of values. Table 1 shows some of the key vision tests and some customizable parameters within the different tests.

Building Additional Configurable Tests

Engineers also want the ability to add more tests and functionality without discarding their existing display inspection system. To this end, the system must be built upon an open software and hardware architecture.

The test-executive approach allows modular tests to be added into the software framework. As shown in Figure 2, the flow of execution is illustrated in the configurable test mode and the execution mode of the display test. The standard suite of tests is easily extended by creating an additional display inspection test using programming languages such as LabVIEW, Visual Basic, C, or C++.

Within a test executive, each test is called a step. A test-executive step does more than call a code module. In fact, it performs numerous operations before and after calling the code module. Some of these operations include evaluating a precondition, executing engine callbacks and step substeps (pre, post, and edit), and accessing status expressions. A list of steps executed within the test-executive framework constitutes a complete test.

All of the various operations of a step interact with each other to provide the desired functionality. Step properties play a key role. They serve as a repository of data that every step operation can use.

Step properties can be thought of as local variables for a particular step. These properties hold configuration information as well as test results. With step properties, every instance of a step type will have its own set of properties. As a result, two steps of the same type can be configured differently.

Conclusion

Reducing manufacturing costs is crucial to producing low margin products such as cell phones and PDAs. This can be achieved by consolidating all of the testing requirements under one software and hardware framework. Not only can display inspection tests be added, but also other measurement and automation tests. In effect, one complete end-of-the-line tester can be created for mobile devices as Flextronics did.

To meet the growing demands of flat-panel display testing, engineers must choose a system that provides the maximum flexibility without sacrificing reliability. In this way, a complete display test system can be created that easily changes as the manufacturing requirements change.

About the Authors

Jason Mulliner is the vision product manager at National Instruments. Previously, he worked as an applications engineer specializing in motion control and image acquisition. Mr. Mulliner received a bachelor’s degree in electrical engineering from Brigham Young University. National Instruments, 11500 N. Mopac Expressway, Austin, TX 78759, 512-683-5364, e-mail: [email protected]

Bryan Moore is a senior software test engineer at Flextronics International. In 22 years as a test engineer, he has worked in vision test system development, avionics RF test, medical product test, and GUI test-executive design. Flextronics International, 2090 Fortune Dr., San Jose, CA 95131, 408-576-7842, e-mail: [email protected]

Return to EE Home Page

Published by EE-Evaluation Engineering

All contents © 2002 Nelson Publishing Inc.

No reprint, distribution, or reuse in any medium is permitted

without the express written consent of the publisher.

June 2002