Here�s some advice to consider when choosing the right DMM for your next test system.

Most automated production test systems require a DMM and usually are integrated into a PCI, PXI, or VXI chassis. These architectures provide a favorable combination of speed, ease of integration, accuracy, reliability, reasonable cost, and small size.

A single PXI chassis can host from two to 18 instruments, providing high density for a medium-sized system. It generally is perceived as more solid mechanically than PC-based PCI test systems. PXI requires either a PXI-compatible computer or a bridge from the PCI bus of a PC.

Generally, using a PC with the PCI plug-in modules is the least expensive way to implement a test system, but it limits you to few modules per system unless you use an expansion chassis. The range of test modules available in PCI format is wider than in the PXI format.

If you need a larger test system, PXI may be the way to go. Most manufacturers of plug-in DMMs offer both PXI and PCI products.

System Software

Once you have chosen a chassis, think about what software you will use to implement your test system. Despite what you may have been told, just about any system can use just about any software to control the test, so selecting the right software is very important.

Consider several issues when making the selection. Development time is important, but so are maintainability and operating speed. Modern software does not require the use of drivers. The software you select should be capable of making direct calls to a dynamic linked library (DLL) without an intermediary driver.

Common languages and environments such as Visual Basic, C++, Delphi, ATEasy, and LabWindows/CVI are very productive. That is, they are structured, allow fairly fast development of the test program, and are straightforward in debugging and troubleshooting. They also are easy to remember and understand.

It is not necessary to get your software and hardware from the same source because one-stop shopping has its limitations. In today�s modular hardware and software environment, choosing the optimal hardware and software products is the way to go, and these can be easily integrated across vendor boundaries.

Trade-Offs of Accuracy, Speed, Budget, and Features

Next, you need to figure out how a DMM might fit into your system. Consider these questions:

� What do I need to measure?

� How much dynamic range do I need?

� How much accuracy do I need?

� How fast do I need to go?

� How many dollars can I afford?

If you have to acquire a waveform, you probably need an oscilloscope or a digitizer. Even the lowest cost scope will have much higher bandwidth and a better triggering facility than any DMM.

If you need several channels of low-accuracy data, a data acquisition card might do the trick. Consider their limited voltage range, poor noise rejection, low accuracy, and lack of isolation. If you require resolution beyond 12 bits and accuracy tighter than 0.1%, you probably need a DMM.

Case in point: One of our customers is using a 16-bit brand-named data acquisition board to measure DC voltages in sensor production. He noted that he is getting 8 mV pk-pk of noise or about 10 bits of effective resolution. To reduce the noise, he is doing extensive averaging, resulting in lower measurement rate, higher noise, and much lower accuracy than a DMM could provide.

But there are several DMMs available. How do you choose among them? This decision is complicated by the fact that things are not always what they seem. It is typical for manufacturers to highlight the highest accuracy and the highest speed of their product. Unfortunately, you don�t get both at the same time.

DMMs generally offer the capability to be slow and accurate or fast and less accurate, but sometimes they don�t tell you what accuracy goes with which speed. The user needs to make sure that the DMM in question has a mode that is fast and accurate enough for the application.

Admittedly, it is not easy to understand the specification sheet of many DMMs. These specifications sometimes are written for the benefit of the manufacturer and not the user.

Some specify accuracy with automatic zeroing turned on and reading rates with automatic zeroing turned off. How fast does the DMM measure with automatic zeroing turned on? How accurate is it with automatic zeroing turned off? Can you select the reading rate or aperture you want? You may have to read between the lines or ask.

Which raises this question: How available is technical support from this vendor? Does the company have the experience to help with your test requirements? Do you have to go through multiple levels of sales people before you can talk to an engineer? We believe that engineering support should be readily available.

We all have to live within budgets. Cost always is a consideration when you design a test system, and it must be weighed against features and performance so that the system meets its goals. You need to consider how many models are available, and if there is software compatibility among the models. If your requirements change during the project, you want to be able to change models without having to throw away your software and start over again.

What Is 6� Digits?

It is customary to describe the dynamic range of a DMM in digits. The current standard for DMMs is 6� digits. However, not all 6�-digit DMMs have equivalent dynamic range.

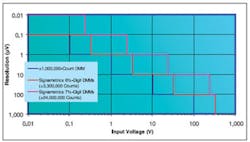

A more accurate way to evaluate dynamic range is counts. One vendor claims 1,100,000 counts are 6� digits while another offers up to 3,300,000 counts as 6� digits. If you need to measure 20 V, the first DMM has only five useful digits while the second retains full 6-digit resolution. Figure 2 depicts input voltage vs. dynamic range and resolution.

Other Measurement Functions

What other features and types of measurements do you need? Do you need to measure capacitance or inductance? Do you need to measure nanoamperes of DC current with picoampere resolution?

Perhaps you need to measure milliohms of resistance with microohm resolution. Do you need to measure leakage currents at a specific voltage? Or do you want to measure temperature with a thermocouple or RTD?

A Feature or Limitation

Taking measurements forces a trade-off between accuracy and measurement speed. A good DMM always starts with an accurate and stable design and uses additional zeroing and calibration steps to ensure the accuracy of the measurements. Some of these steps take away from measurement speed to improve the accuracy.

When excessive zeroing steps are required to ensure the desired accuracy, the underlying circuitry may have too much drift and noise.

Passive Front End?

A DMM, like all measurement devices, must be passive to minimize the effect of the measurement on the circuit under test. When evaluating DMMs, investigate whether the DMM in question is truly passive for the appropriate measurements.

If the DMM input generates transient pulses, short as they may be, these pulses affect the circuit under test, degrading the accuracy of the measurement. In particular, short pulses charge circuit capacitances and turn on semiconductor junctions, altering the measurement results in an unpredictable way.

Input Resistance

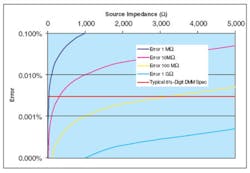

Standard input resistance for the better DMMs is >1 GΩ for the lower VDC ranges and 10 MΩΩ on all ranges. There actually is one plug-in DMM that has only 1-MΩ input resistance on all ranges, which is very substandard. for higher ranges. Low-end DMMs, such as inexpensive hand-helds, usually have only 10 M

To accurately measure circuits or sensors that have high internal resistance, you must have a DMM with at least 1-GΩ input impedance. Better DMMs automatically provide this high input impedance. Other models require you to select the input impedance.

We know of one DMM that programs to a high input impedance but defaults back to 10-MΩFigure 3 shows the effects of a sensor�s impedance on front-end resistances for three DMMs. input impedance when commanded to take a reading, defeating the selection and potentially altering the measurement. The interaction of high source resistance of a circuit with the input resistance of a DMM could cause measurement errors that are orders of magnitude higher than the DMM spec.

Measuring Current

When measuring current, DMMs use current-shunt resistors to turn the current into a voltage. A DMM with multiple shunts can measure currents with lower burden voltages that are less disruptive to the unit under test (UUT). Other DMMs may have no shunt or only a single current shunt and burden voltages as high as 3 V.

As an example, many test procedures start out by taking basic measurements such as operating current. This measurement determines whether the UUT is working well enough to warrant a more comprehensive test. If a typical current drain is around 0.5 A, a DMM that measures this current using a 0.05-V drop will not disturb the circuit as much as one that measures 0.5 A using a 0.5-V drop. In fact, if the circuit uses a 3.3-V power supply, a 0.5-V drop in that supply will prevent it from working at all.

On the other end of the current measurement scale, the Signametrics SM2064 has five shunts and measures nanoamperes of current with picoampere resolution while imposing a burden voltage of less than 1 mV on the circuit under test.

Measuring Resistance

If you are measuring resistance, the key question is how many current sources are available. Some DMMs have as few as four current sources to cover seven ranges of resistance. To make up for it, they force test voltages over 10 V across the resistor being measured, which doesn�t work if it is in a circuit. Other DMMs use seven current sources to cover eight ranges. This enables them to maintain full resolution at lower test voltages. This is a must for in-circuit measurements.

If you need to measure low value resistances, a DMM with a 10-mA current source is very handy. It enables the DMM to measure milliohms with 10-ï¿½Ω resolution. This is particularly useful if you need to measure the contact resistance of a connector, a socket, or a relay.

It also is helpful if you are measuring the resistance of a wire harness or a copper trace on a PCB. These require the capability to measure 10 mΩ and discern differences of less than 1 mΩ. These are situations where the capability to resolve small differences usually is more important than high accuracy.

Some DMMs use 10 �A to measure 1 MΩ, which allows them to have a very high accuracy specification. However, the 10 V that they impose on your UUT means that you probably won�t achieve that accuracy in reality because it will be clamped by semiconductor junctions.

A better choice would be a DMM that uses 1 �A to make the measurement. This forces some compromise in accuracy specifications, but the 1 V that it imposes on your UUT means that you actually can achieve that accuracy in practice.

Triggering

When you need to capture a transient event, a high sample rate is not the only important thing. Good triggering capabilities and adequate analog bandwidth also are essential. Some DMMs feature a high sampling rate but have limited triggering capabilities. They also have only enough analog bandwidth to provide about 0.5% accuracy at 20 kS/s. They can generate much data that bears only a loose relationship to the event they claim to be measuring.

Multiplexer

Last but not least is what you use to multiplex signals into your DMM. If you are measuring signals that are less than 1 V, the multiplexer can introduce digital noise and offset voltages into the measurement that cause significant errors, to the point where your overall system accuracy is much worse than the DMM spec. A high-density multiplexer specified to switch 2 A probably is not a good choice for instrumentation applications.

Conclusion

PCI and PXI plug-in test systems are the most compact, affordable, and easiest to integrate. For these reasons, they are best suited for most of today�s test and measurement requirements. PCI allows fast and low-cost development of small test systems while PXI is more suited to larger and more complex systems.

Plug-in DMMs for PCI and PXI are coming of age now with resolution up to 7� digits, enhanced functionality such as LCR, 4- and 6-wire resistance measurements, leakage-current measurement, and temperature measurement. Choosing the right DMM for the application now is easier with the availability of a larger selection of DMMs with a variety of price/performance features.

Integrating any plug-in module with standard test software is easier with the advent of modern software DLLs and allows you to choose the optimal hardware and software combination across vendor boundaries. Integration with the right switching (multiplexer) module is imperative to retain the accuracy facilitated by the new modern plug-in DMMs.

As with any other engineering project, choosing a vendor with competent and easily accessible technical support and using that support to choose the best combination of products are paramount to your test-system development.

About the Author

Paul Lantz, a 33-year veteran of the test and measurement industry, is vice president of engineering at Signametrics. His professional experience includes a long career at Fluke where he held a number of engineering positions including engineering section manager and principal engineer. Mr. Lantz received an M.S. in electrical engineering from New York University. Signametrics, 6073 50th Ave. NE, Seattle, WA 98115, 206-524-4074, e-mail: [email protected]

February 2005