Three tests�shaking a product first in the X axis, then in the Y axis, and finally in the Z axis�are not realistic. But MIL-STD-810, published in 1962, revised six times since 2000, and currently in its F revision, has only offered the single-axis-at-a-time method. However, the G revision, scheduled

for release in May 2008, will include the new Multiexciter Test Method 527.

Testing Automobiles

We all know that real-world vibrations exist simultaneously in multiple axes. For instance, our automobiles receive six inputs from the road: vertical, fore-and-aft, and left-and-right linear in addition to pitch, roll, and yaw angular.

Automotive testing long ago evolved from vertical-only mechanical shaking to multiple exciter single-axis (MESA) to the current multiple exciter multiaxis (MEMA). Today, many automobile manufacturers worldwide use multiple long-stroke electrohydraulic (EH), sometimes called servohydraulic, shakers to accomplish such tests.

Multiple EH shakers drive each of the four wheels of complete vehicles. Major automotive assemblies needing vibration tests are mounted on a MEMA vibrating platform.

Multiple Electrodynamic Shakers

That is well and good for automotive shaking to 200 Hz, perhaps to 500 Hz. But for airborne applications, you need to shake to 2,000 Hz. For that reason, electrodynamic (ED) shakers are used.

For example, the U.S. Army Research Lab at Adelphi, MD, pioneered the use of three mutually perpendicular ED shakers in response to a land-vehicle assembly that frequently failed in the field. Single-exciter-single-axis (SESA) shaking could not replicate the failure.

Army researchers hoped that MEMA shaking would replicate the failure. The hope bore fruit, and several similar instances have occurred over the years. This system can shake vertical only, north-south only, east-west only, or any combination of axes including all three simultaneously.

A second system was installed at White Sands Proving Ground in New Mexico. However, to my knowledge, that MEMA system has had little use partly because 810F is SESA oriented.

The U.S. Navy recently acquired a MEMA system at Keyport, WA. The U.S. Air Force owns and Boeing operates an eight-shaker MEMA system that goes a step or two further. It also vibrates roll-only, pitch only, yaw-only, or all six axes (6DoF) simultaneously.

The three or six ED shakers are connected to a common fixture to which the test article is attached. Isn�t the north-south shaker, for example, damaged by the east-west shaker and the up-down shaker and vice versa?

The answer is no. Between each shaker and the common fixture is a zero-backlash mechanical connection that transmits axial vibration but accommodates needed misalignment. When the controls for a triaxial shaker array are set for pure up-down motion, unwanted lateral motion of the up-down shaker is actively controlled by the north-south and the east-west shaker systems.

Commercial Multiaxis ED Shaking

Perhaps the military with their relatively vast budgets can make such investments. But many commercial enterprises may think they can�t afford three ED shakers, each with its own power amplifier and control channel.

Many years ago, I sold ED shakers. Some potential customers balked at buying even one, citing the considerable expense. Within a year or two, many of those same customers owned several shakers because the first was in such heavy demand.

Three-axis shaker systems similar to the one shown in Figure 1 are said to be quite common among Japanese automobile manufacturers. On a related note, Spectrum Technologies claims to be the only U.S. commercial environmental test lab having three-axis ED shaking capabilities.

Figure 1. Three-Axis ED Shaking

Courtesy of IMV, Visteon, and Spectrum Technologies

Economical Solutions

Status Quo

Although not recommended, continue to use your existing ED shaker. It, like all ED shakers, has some lateral motion�uncontrolled. Perhaps you�ve discovered this for yourself by attaching lateral accelerometers in addition to your axial accelerometer. Does this provide sufficient lateral vibration for Method 527? No.

Tilt Fixture

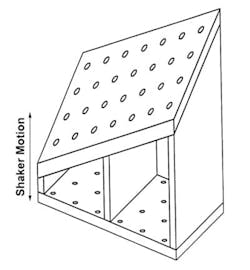

Figure 2 illustrates a tilt fixture that skews the test article relative to shaker vibratory motion. In my opinion, this is not multiaxis vibration. True, there is a component of motion in the X, Y, and Z axes, but the correlation is 100%. You are not simulating the real world where a specimen�s X, Y, and Z inputs often are much different.

Figure 2. Tilt Fixture

Variable Repetition Rate Hammering

Another approach is variable repetition rate hammering. It could be described as several nonsynchronized pneumatic hammers on different but adjustable compass headings tilting upward into the bottom of a softly sprung 6DoF horizontal multiaxis platform. The nonsynchronized programmed repetition rate hammering results in translational and rotational motion.

The platform serves as the bottom of a varying-temperature chamber. Test articles atop the platform receive thermal cycling plus multiaxis vibration. Several manufacturers offer these highly accelerated life testing (HALT) and highly accelerated stress screening (HASS) chambers. They effectively stimulate failures; there is no attempt to simulate the real world.

Without question, variable repetition rate hammering induces failures by simultaneously exciting all test article resonances. Such units are being used widely to find design and production weaknesses in electronic assemblies. But many reliability engineers question the use of a tool whose vibration is poorly controlled in both the time and frequency domains. Repeatability is questionable.

About the Author

Wayne Tustin founded Equipment Reliability Institute, an engineering school dedicated to increasing the reliability of military, commercial, and personal equipment. Equipment Reliability Institute, 1520 Santa Rosa Ave., Santa Barbara, CA 93109, 805-564-1260, e-mail: [email protected]

September 2007