This article is part of the RoHS and Critical Materials in our Series Library.

The element lead has a long history of use, sometimes with bad outcomes due to its toxicity when ingested. Lead is also a vital constituent of today’s electronic components, solders, batteries, photovoltaics, and metal alloys. Here we provide some perspectives about past, present, and future use of lead and how we may control its distribution around the world. Improvements in the lifecycle of lead are needed to conscientiously manage the use of this unique element where it’s needed to perform critical functions, while preventing unintended consequences when improperly released or discarded into the environment.

Lead been used for over 5,000 years. Its desirable properties include a low melting point compared to other metals, an ability to be ductile and malleable, and its utility in a variety of alloys such as brass and solders. In ancient times, alchemists associated lead with the planet Saturn, and the two even shared the same symbol, highlighting how lead has been part of history for millennia.

From a modern perspective, lead is in the same periodic table group as carbon, which is the basis for life as we know it, yet lead is toxic to life itself. In between the two lie the elements germanium, silicon, and tin, which should also sound familiar to Electronic Design readers.

Lead vessels and pipes were used in the days of the Roman Empire, and although not conclusively proven to be the reason for the Empire’s collapse, the Romans’ pervasive use of lead and the Empire’s later fall continues to this day as a cautionary tale for how lack of attention to where lead is used can cause problems. More recently, the use of automotive gasoline containing lead anti-knock compounds peaked in the 1970s, and has since declined, with lead-free gasoline now being burned by unleaded gas-compatible engines. In the meantime, lead and lead compounds were deposited from vehicle exhaust in unsustainable amounts near roadways.

While lead poisoning doesn’t often cause death any more, the greatest concern today is with childhood poisoning that seriously affects mental development. Drinking water with high concentrations of lead has been headline news in recent years.

Issues related to lead in municipal water supplies aren’t highly technical at all; they’re about archaic and aging infrastructure, plumbing, and, to some extent, the result of social injustices because these shortcomings occur more often in poor and neglected communities. At minimum, measures like the U.S. Safe Drinking Water Act of 1974 need to be maintained rather than relaxed, with resources provided for enforcement.

The high volumes of discarded electrical and electronic equipment (EEE) in particular has resulted in regulatory restrictions and recovery requirements, led by the European Union and adopted in other countries and states like California. Here’s a short list of the regulations relevant to EEE:

- European Commission (EC) Directives: RoHS, Restriction of Hazardous Substances; WEEE, Waste Electrical and Electronic Equipment; ELV, End of Life Vehicle.

- European Chemicals Agency (ECHA) Directives: REACH, Registration, Evaluation and Authorization of Chemicals, specifically the Candidate List of Substances of Very High Concern (SVHC).

- Proposition 65: California Office of Environmental Health Hazard Assessment.

These laws operate at several levels: to ban usage of certain toxic substances, including lead and its compounds, while allowing exemptions for specific applications where there’s no alternative but subject to periodic review (RoHS); reporting to the public on safe use of substances of very high concern (SVHC), including lead and selected lead compounds (REACH); and setting collection and recovery targets for electronic waste (WEEE). Similar legislation applies to end-of-life vehicles (ELVs). Proposition 65 in California further requires a warning label on products where lead or certain lead compounds pose a risk of exposure.

These regulations all drive reduction in the use of lead and toxic substances in the first place. Moreover, they prompt total lifecycle considerations with environmentally sound, long-term goals of a circular economy and closed loop material flows.

Current Use in Electrical and Electronic Materials and Components

Why do we continue to need lead? Its major usage today is the lead-acid storage battery for starting vehicles. It’s the material of choice for X-ray shielding and has smaller but critical usage in high technology. In electronics, lead is used in metal alloys, ceramic components, and solders.

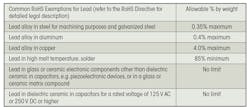

The table lists critical usages of lead, together with their corresponding existing exemptions from the EU RoHS Directive. Notably, these exemptions come up periodically for renewal. The actual legislation is somewhat more complicated than shown in the table in terms of specific usages, but the examples given have broad applicability to electronic products produced in high volume.

RoHS exemptions all have a predefined review date, at which time a decision will be made by the European Commission to continue or modify the exemption, or render it expired and no longer active. July 2021 is not far away. This July 2021 review date applies to the following categories of equipment covering a broad spectrum of familiar and high-volume products. (More specialized categories like medical devices, monitoring and control instruments, and automatic dispensers have their own review cycle and aren’t listed here).

- Large and small household appliances

- IT and telecommunications equipment

- Consumer equipment

- Lighting equipment

- Electrical and electronic tools

- Toys, leisure, and sports equipment

Lead provides the important property of allowing certain alloys of copper, aluminum, and steel to be machined. Copper specifically is used widely in electrical connectors, while aluminum and steel may also be employed in electronic products.

Solder is critical to electronics assembly. Prior to the restriction of the original RoHS Directive, the solder alloy of choice for most electronic assembly, eutectic 63/37 tin/lead, was largely replaced in many markets even outside of the EU for compliance by 2004. Higher-temperature solder requires much higher concentrations of lead, typically greater than 85%. These solders are critical to applications like two-temperature reflow assembly and in high-temperature applications where the lower melting eutectic solders are inadequate for performance and reliability.

High-temperature solder is used in modules and hybrids and to provide internal connections in high-temperature relays. Other familiar components that may use high-temperature solder internally include die attach in power semiconductors, and in potentiometers and capacitors.

Lead in glass and ceramic components provides important properties for sealing and adhesion, mechanical strength, and overall reliability. Familiar components of this type include sensors, transducers, and chip resistors. For piezoelectric devices, lead zirconate titanate (PZT) is the most commonly used material for ceramic resonators and in sensors and transducers, including audio alerts and ultrasonic devices.

There’s a severe lack of suitable substitutes for lead in machinable metals, high-temperature solder, and glass or ceramic components. Recent work by multiple industry task groups has found that in most cases, there currently are just no viable replacements for current usages of lead. These findings are independent of material cost concerns, since substitutes for the performance of lead and its properties are simply not known yet, while any possible substitutes may bring drawbacks of their own. Detailed technical dossiers are being submitted to the European Commission for extension of the RoHS exemptions for lead.

Lead metal and 17 specific lead compounds are also listed as SVHC under the REACH Directive. While this isn’t a ban or restriction, it does require public reporting when such substances are present in >0.1% by weight of the article. Again, their use is based on critical need for performance, which in the case of piezoelectric devices provides the fundamental interaction between electric charge and mechanical stress that makes them so useful. Besides lead metal, these four lead-oxide compounds are categorized as SVHC and are commonly be found in small amounts in components made of ceramics and glass:

- Lead monoxide

- Lead tetroxide (orange lead)

- Lead zirconium trioxide

- Lead zirconate titanate (PZT)

Future Use and Prospects

While review of current lead usage and research on alternatives continues, new technology is finding the utility of lead to assist with the growing need for sustainable energy. For example, lead in the form of pervoskites, which is a specifically defined crystal structure that may be based on lead iodide, is one of the promising materials for the rapidly developing photovoltaic industry.

Lead is a naturally occurring element, unlike synthetically manufactured compounds. This fact distinguishes the lifecycle of lead versus, for example, certain flame retardants and dielectrics, two groups of which were banned by RoHS in 2004. Substitutes were found but concern still remains about their long-term effects to the environment being fully understood.

In the case of lead, which is found in nature, what’s needed is more environmentally benign mining, controlled use in manufacturing to prevent unwanted releases to workers and the environment, and collection and recovery from end-of-life products to close the material loop.

Today’s lead recovery efforts are dominated by processes built to recycle used lead-acid storage batteries. For other types of consumer electronic equipment, the phrase “Urban Mining” has been coined to describe the ability to obtain value from large volumes of discarded consumer goods.

These reclamation efforts target high-value metals, notably copper and the precious metals gold, silver, platinum, and palladium, while other metals, like lead, kind of go along for the ride with discarded goods and are collected for recycling. Still, the high-volume recycling of metals including lead is thus becoming more of a circular economy as it should be.

To comply with original RoHS and for global manufacturers who themselves have adopted the same requirements, the move away from eutectic tin-lead soldering of printed circuit boards and component terminations in the early 2000s has reduced the lead content in electronic products. As fully electric vehicles continue to rise in market share, the use of lead-acid batteries—no longer needed to start the absent internal combustion engine while other battery technologies like lithium ion are used instead—will decline as well.

It remains to be seen how the promising lead-containing perovskite photovoltaic technologies will grow in the future. If these new applications of lead grow significantly, recovery and recycling flows for lead will need to adapt.

Lead Recovery and Recycling

Recovery of lead is well established, with metal smelting operations using both as-mined ores and end-of-life product recovery streams as feedstocks. The inputs for these operations need to be dynamically adjusted according to feedstock availability and composition. Discarded leaded-glass cathode ray tubes from televisions and monitors are a sub-specialty with volumes that have recently peaked in end-of-life treatment. They should also decline in the next few years with flat-screen technologies taking over the display market.

While specialized usage of lead can’t currently be substituted or replaced for the listed electronic applications, a conscientious effort should be brought to bear by both industry, governments, and informed consumers to further improve closed-loop recovery of lead. For all sectors where lead is still required for product functionality, recovery and lifecycle management rather than discarding as waste is key. As automotive lead-acid battery volumes decline, we need to assure that newer lead-containing PV technologies are built out with closed-loop material recovery already planned in.

Once recovered products have entered the recycling process, which in most cases will be a dedicated metal smelter or combinations of secondary and primary smelters, these operations should adhere to best practices for environmental safety. Newly mined ore is generally one of the feedstocks, which in the case of lead is typically galena, or lead sulfide.

Various regulatory agencies publish guidance on Best Available Technique, sometimes called Best Available Technology, and related documentation such as Best Available Control Technology, for mining and metal recovery and refining operations. Adhering to these guidelines means that both ore mining and metal recovery have practices in place to control emissions of dust and other airborne releases, scrubbing of sulfur rather than releasing sulfur oxides to the air, containing such operations in closed systems, and using energy-saving practices like heat recovery.

While these recycling operations still carry some environmental footprint, best practices specifically defined for lead assure that the recovery of refined lead back to the stream of commerce is done responsibly in a closed loop. Lead and other metals can be recycled virtually without end, unlike other materials like paper and plastic, whose performance degrades in the recycled output.

Outside of the industrial sector, a broad interdisciplinary effort including public and private health awareness and action is still needed to recognize and address basic flaws in water delivery to worldwide populations. This recommendation, written two decades ago, still stands in need of attention today: “Pediatricians and public health entities should continue in their efforts to reduce the lead burden through environmental control and ongoing surveillance.”

New science and high technology aren’t critical to fix corrosion in lead-containing pipes and aging infrastructure. We only require the determination to do so. Controlling the distribution of lead globally, including lifecycle management of end-of-life electronics, will ensure lead is kept out of drinking water supplies in the first place. In fact, this even older quotation from Benjamin Franklin is still sound advice: “A place for everything, everything in its place.”

We end with these two final recommendations for the electronics designer:

1. Be aware of existing and future environmental regulations and seek to replace substances like lead at every opportunity.

2. Be a responsible citizen with your own unwanted electrical and electronic goods, and facilitate the development of recovery streams wherever possible. Also encourage the same closed-loop thinking by your company.

References

Quotation is from A.L. Mendelsohn et. al., Journal of Developmental and Behavioral Pediatrics (JDBP) Vol. 20, no. 6, pp. 425-431 (1999).

US Geological Survey, National Minerals Information Center https://www.usgs.gov/centers/nmic/lead-statistics-and-information

International Lead Association, https://ila-reach.org/

Read more articles from the RoHS and Critical Materials in our Series Library.