What you’ll learn:

- CAN’s long reign as the heart of vehicle communications is set to be challenged by Ethernet.

- This shift toward greater connectivity will play a decisive and accelerating role in the move toward Ethernet backbone networks.

- The automotive industry is transitioning to an Ethernet-based Zonal E/E architecture.

- Ethernet’s “plug and play” capabilities are uniquely suited to the high-performance, service-oriented environments that will define the future car.

For 30 years, controller area network (CAN) buses have been at the heart of vehicle communications, supporting a diverse array of automotive innovations. However, automotive technology has come a long way since the first CAN buses were deployed in 1991. And as increasing connectivity transforms vehicles into data centers on wheels, CAN has been tasked with more and more functions well beyond what was envisioned 30 years ago.

Robust and reliable, CAN remains a favorite of automakers even into its fourth decade. But as the automotive industry undergoes a paradigm shift in response to cutting-edge technologies and fast-evolving consumer demands, CAN’s long reign is set to face new challenges. Moving forward, Ethernet will increasingly function as the automotive network’s backbone, offering a higher performing, more secure, and more efficient alternative to CAN buses.

Market analytics projects that the global connected-car market will reach $225.16 billion by 2027, up from $63.03 billion in 2019. This shift toward greater connectivity will play a decisive and accelerating role in the move toward Ethernet backbone networks, even as CAN buses continue to form an important communication medium (mainly in legacy components).

CAN’s Advantages—and Limits

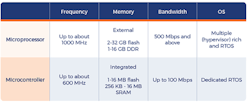

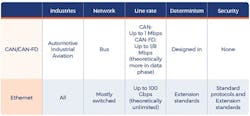

The technical features of CAN have made it particularly effective in the vehicular environment, starting with its high tolerance for noise, supported by CAN’s physical layer and protocol. In addition, CAN supports native multicast and broadcast, provides built-in frame priorities, offers non-destructive collision resolution, is 100% distributed in operation, and easily supports long single buses measuring in the tens of feet. Only two-wire and with a cheap physical-layer interface, CAN still provides the most “bang for its buck” in traditional automotive networking.

However, with a single CAN bus limited to a maximum data-transmission rate of 8 to 10 Mb/s, it’s struggling to keep up with the demands of today’s connected vehicles. In addition, as more devices become connected to the same bus, it greatly decreases the bus’s performance.

Automakers have circumvented this problem by adding more CAN buses to vehicles, with some current models hosting more than 10 buses. The ad hoc connections between these buses have been sufficient in terms of facilitating network communications, but security is typically an afterthought, despite connected vehicles’ increasing vulnerability to cyberattacks.

Upgraded versions of CAN—including CAN-FD and CAN-XL—aim to improve on the basic version by supporting more throughput (from 1 Mb/s in traditional CAN to 8 to 10 Mb/s in CAN-FD/XL), faster line rates, and larger frame sizes. CAN-FD is already in production, while CAN-XL is still in the design phase. Though these improvements will undoubtedly enhance CAN’s robustness and reliability as cars become more connected and autonomous, Ethernet offers yet another pathway to building a vehicle communications network that meets modern needs.

Ethernet and the Connected-Car Evolution

To meet the demands of cars that will soon run on many hundreds of millions of lines of code—compared to 50-100 million lines for current models—the industry is transitioning to an Ethernet-based Zonal E/E architecture. Ethernet’s “plug and play” capabilities are uniquely suited to the high-performance, service-oriented environments that will define the future car. Devices can be connected and disconnected in real time, with zero downtime, marking a significant advantage over CAN buses.

There are drawbacks to Ethernet, including a more expensive physical-layer interface, the costs associated with required switches, and complications surrounding EMI and EMC issues with two-wire unshielded twisted-pair (UTP) Ethernet. Moreover, Ethernet communication is non-real-time and non-deterministic.

From the standpoints of overall performance, Ethernet offers distinct advantages that necessitate its integration into a mixed-criticality automotive architecture. By supporting quality of service, security, time-critical extensions (e.g., time-sensitive networking, or TSN), and significantly higher performance, Ethernet enables the high-performance communication required in Zonal architecture.

To achieve similar performance, CAN will need more wiring and more components than Ethernet, thus resulting in higher costs. With Ethernet, wiring harnesses are smaller, requiring smaller investments of time and resources than the installation of often-ungainly CAN systems. This simplicity also makes it easier to rapidly identify and troubleshoot problems in vehicle functionalities.

The transition to service-based communication and modular design are inherently supported by Ethernet-based architectures, rather than CAN buses, given Ethernet’s greater flexibility. This will prove crucial as hundreds of millions more lines of code are added to future car models, along with new infotainment capabilities, safety-critical features, over-the-air (OTA) updates, and autonomous and semi-autonomous features.

The Outlook

Frost & Sullivan estimates that some 400 million automotive Ethernet ports are currently in use. By 2022, there will be more automotive Ethernet ports than ports for all other interfaces combined.

While those figures attest that Ethernet’s penetration is already growing, the automotive Ethernet market is still in its early days, with rapid growth expected in the years ahead. ResearchAndMarkets.com predicts that the market will climb from $1.635 billion in 2019 to $4.367 billion by 2024, driven by rising demand for advanced driver-assistance systems (ADAS), infotainment systems, and luxury cars.

Although Ethernet is on the rise largely because it meets needs that CAN buses don’t serve as easily and efficiently, Ethernet will not entirely displace CAN and will in fact complement it in many vehicles. The need for a combination of CAN and Ethernet is clear when considering evolutionary E/E architecture design, where new and high-end electronic control units (ECUs) coexist on the network with legacy ECUs that can be several generations old. In addition, for many traditional automotive networking use cases, CAN is still more cost-effective.

New car models require a robust Zonal E/E architecture and support for numerous applications, which in turn requires a high, and fast, communication load with extremely low latency. This calls for the transition into high-bandwidth communication and aggregation of sensors or actuators into a single link from the zonal gateway to the backbone. Furthermore, high-performance sensors require high-bandwidth communication with the ADAS ECUs.

In future vehicle architectures, Ethernet can enable TSN as a solution for deterministic performance, allow for fiber-optic integration as an EMI/EMC solution, and deliver 1G and 10G links for a high-performance backbone. And Ethernet can do it all with such efficiency that its lack of real-time capabilities is a moot point.

Moving forward, if wire length issues are resolved, 10Base-T1s can serve as a replacement for CAN. Through authentication, secure session establishment, and encryption, Ethernet-equipped vehicle architectures will power secure vehicle communications while also saving costs by integrating switches into security operation centers.

Conclusion

As technological innovation proceeds at its current rapid pace and consumer demands evolve in tandem with it, a wide range of new applications and connected features will be integrated into vehicles—everything from more sophisticated ADAS to in-car gaming consoles. Rolling out these capabilities will require more bandwidth, lighter hardware, and minimal latency, which is why more automakers are taking a hard look at the differences and applications between Ethernet and CAN.