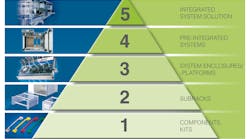

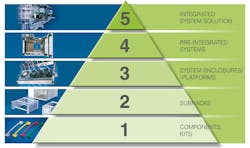

Systems integrators provide their customers with a range of solutions (Fig. 1) depending on their requirements. High-tech enclosure integration is often required and can be challenging if done in-house. I spoke with Roland Chochoiek, Executive Vice President, Electronics Business Unit, HEITEC AG, about some of these challenges and what they can provide as solutions.

1. HEITEC System Integration’s offerings scale from Level 1 to Level 5.

HEITEC is a leading provider of packaging solutions. How would you, in short, describe the role that enclosures play in high-reliable applications?

The enclosures of applications designed for continuous, reliable operation are more than just packages. In fact, a significant part of a product’s technical and commercial success relies on selecting the right enclosure solution meeting the functionality and design requirements. To give you an example, HEITEC designed an enclosure for a supplier of communications solutions, tetronik, as part of a long-standing cooperation. The result was a solution optimally tailored to the customer’s requirements, and the enclosure is the perfect framework for high-performance electronics.

Heiko Trapp, managing director of tetronik GmbH, said that enclosure is “a significant part of our product. Meeting the defined requirements during production was important in order to fulfill the legal requirements.”

Can you tell us a few more details on the target application, its specific electronic characteristics, and deployment areas?

Across many industries, tetronik GmbH is a company specializing in alert and crisis communications solutions. The company’s DAKS solution portfolio can be used to simplify and accelerate communication processes. It protects and alerts, empowers employees to become more mobile, optimizes the accessibility by phone and multimedia, and reliably automates recurring processes.

Roland Chochoiek, Executive VP Electronics, HEITEC AG

Custom solutions exist in many different industries, including the healthcare sector, power companies, manufacturing operations, transportation, financial services, public facilities, police, fire departments, and disaster control. A variety of functions enable event-based, automated communication processes including all-points bulletins, alerting of persons, personal security functions, crisis conferences, as well as extended alerting functions for rescue services. The applications used for these tasks can be installed in parallel on the DAKS alarm server, optionally complemented by multiple functions including various data interfaces, custom user interfaces and much more.

Highly available and robust solutions can be built with the server’s complex, specialized electronics. Densely packed electronics as well as various form factors tailored to the specific application case define the framework for the device enclosure.

Which criteria led to the customer’s decision to cooperate with HEITEC, and what steps of this cooperative effort were most significant?

With the goal of low-cost, fast production of a modular product range, tetronik looked for a partner who was capable of providing an enclosure solution offering maximum flexibility and short implementation times. The easiest way to achieve this was by using a maximum percentage of standard components and selecting a partner with the necessary expertise for optimal component selection, the implementation of custom elements, and the partial integration on levels 3 and 4 (build-up of the enclosure including pre-integration of the system) (Fig. 1, again). tetronik selected HEITEC because the company, based in Eckental (Germany), provided the most convincing concept for the aspects mentioned, particularly because of its technological bandwidth.

The result is a 19-in. desktop enclosure with handles for easy installation in a service rack (Fig. 2). Because of its standard form factor, customers can ergonomically tailor the enclosure according to their needs. In addition to building the enclosure and integrating the electronics, HEITEC was also responsible for quality assurance and mechanical functional tests. The project was accomplished in an ambitious timeframe.

2. The enclosure is designed to fit in a 19-in rack.

Even highly individual requirements could quickly be met thanks to the company’s in-house capacities. For instance, the enclosure’s front plate had to match the customer’s corporate design with a new logo applied in multi-color print technology. The variety of color samples provided by HEITEC in a very short time would have been much more difficult to obtain with multiple partners, locations, and production steps.

Can you describe a few key points of the project, i.e., the combination of standard and customized parts and the required features?

The enclosure structure, including the side walls, is based on 19-in. technology. The connection bars were standardized as well (CompactPCI). Thus, it was possible to provide the mounting space for the desired partitioning scheme quickly and easily. On the other hand, the guide bars were matched to tetronik’s component population requirements by finding the ideal mix between standard and custom components. The customer-supplied hardware component (the backplane) was mechanically integrated by HEITEC and flexibly adopted to the proprietary technology (Fig. 3).

3. The CompactPCI system requires additional fans for ventilation.

Secondly, the cooling requirements of the modular assemblies deserve particular attention. Specially perforated bottom and cover plates were developed to ensure optimum passive ventilation of the densely packed electronics even without additional fans. Furthermore, the electrical and mechanical safety requirements and the legal EMC requirements were met as well.

From your perspective, which were the most significant insights gained from this project?

With the right partner who partly takes care of partner management tasks and provides the best solution for individual customer requirements thanks to its development, purchasing, manufacturing, quality assurance, and services capabilities, advanced enclosure solutions for sophisticated applications can be implemented in a fast and economical manner.

In the described case, the mechanical enclosure components were selected by HEITEC. Standard components were used maximally and modified if necessary, and applicable and custom electronic components were integrated into the enclosure. Advanced enclosure technology and effective manufacturing capacity are prerequisites for the high-tech products of a communication systems supplier.

Roland Chochoiek holds degrees in Electronics and Business Administration and worked in a number of senior management positions within the high-tech industry, including Force Computers, Solectron/Flex, and Rittal. Since 2010, he has served as Executive Vice President of the Electronics Business Unit of HEITEC AG. HEITEC AG is represented in the U.S. by its partner Wakefield-Vette.