Thermoelectric Cooling for Projection Lasers

What you’ll learn:

- How laser diodes have become the technology of choice in laser projection.

- Thermal challenges posed by laser diodes.

- Details on why is thermoelectric cooling the most effective thermal solution.

Laser projectors used for entertainment applications utilize laser modules to generate 4K-resolution images with up to 75,000 lumens and a robust color palette. While commercial laser-projector systems have quickly evolved to be more energy-efficient, these systems still require up to 6 kW to generate bright, high-resolution images (Fig. 1). Consequently, the high-power laser systems generate a significant amount of heat during operation. Heat can degrade the sensitive laser components, including the laser module (laser diodes and laser optics), laser-diode driver electronics, and optical scanning system.

Such systems need to maintain a stable temperature to ensure proper functionality, long life operation, and crisp image projection. Efforts to increase luminance and color palette resolution while maintaining the size of a laser projector have resulted in significant thermal challenges for many manufacturers. By utilizing ambient liquid loop systems with thermoelectric coolers, laser projectors can maintain the optimum operating temperature.

Application Overview

A commercial laser-diode projector used in cinema or a light show at a concert generally consists of one or more lasers—red, green, and blue. These are combined with an optical scanning system and various drive electronics, all integrated into a laser housing.

Compared to traditional lamp projectors, laser projectors offer a wider range of colors, a sharper contrast, and can project at further distances. Laser projectors are able to provide exceptional image quality with outstanding 2D and 3D brightness, high contrast, uniformity, and superior color performance.

A laser light source is more energy-efficient than conventional lamps because the laser output can be precisely tuned to produce the required red, green, and blue wavelengths rather than wasting power on unusable frequencies. The life expectancy of lasers is also longer—replacements are typically required after 20,000 hours—which is more than 2X longer than lifetimes of projection lamps. Compared with traditional lamps, at startup, a laser projector is virtually instant with consistent brightness maintained over its working life.

Laser-diode technology has become the standard for projector laser modules because of its ability to produce a wide color pallete and range. An electrical current is applied to a laser diode, which is then passed through a laser crystal to create laser light. Providing sufficient cooling for the light source (and other elements of the projector’s light engine) starts with the projector manufacturer providing a good thermal design to ensure laser-produced heat is adequately vented away from the projector’s light engine. The lasers used in these systems can generate heat from 100 up to 300 W.

Application Challenges

Laser diodes can be unstable and their lifetimes may be shortened without proper thermal management. OEMs face several thermal challenges such as achieving desired temperature control while managing heat-transer throughput under tight space constraints, including size, weight, and power (SWaP). Also outgassing from materials can be a concern as this can coat the lens of laser.

Heat

Lasers inherently produce heat during operation, which must be managed and efficiently dissipated to ensure high-quality image resolution. Laser-projection manufacturers continue to use higher-powered laser systems to improve illumination and the color palette, which generates more thermal noise. Combine that with the trend toward miniaturization for enhanced portability and simplified installation and managing the heat flux density becomes even more challenging. Smaller thermal devices must deliver higher heat-pumping capacities to meet these design complexities.

Condensation

Sensitive optoelectronic components are negatively affected by condensation. Moisture forms on cold surfaces as temperature drops below dew point. If this moisture seeps into the electronics, it can cause the electronics to fail.

It’s therefore important to protect electronics against condensation, even for applications where the setpoint temperature is at 20⁰C. The cold side of the thermoelectric cooler ceramic can be at 10⁰C or colder to maintain that setpoint temperature. This will most likely be below the dew point and cause moisture in air to condense.

Because epoxy or RTV sealing of the thermoelectric cooler will not be sufficient, it’s recommended to have a secondary insulation barrier to protect the thermoelectric-module (TEM) cavity. All surfaces that go below the dew point will require some type of insulation to keep moisture from condensing. This is usually done by insulating with a closed cell foam or other type of insulation that doesn’t absorb moisture, nor outgas, and has good thermal insulating properties.

Outgassing

Outgassing can affect image quality by coating the light source or optics in laser systems. It’s best to use a thermal interface material on either side of the thermoelectric cooler during assembly to maximize thermal conductivity. However, standard thermal interface materials, such as greases, can outgas and contaminate the lens.

Special thermal epoxies and phase-change materials exist with low outgassing characteristics, but these should be baked in an oven prior to installation to make sure all outgassing has been released. Another mounting method is to specify thermoelectric coolers with metallized exteriors and solder with a low temperature solder. In this application, indium-tin (InSn) solder is typically used that melts at a temperature below the solder construction of the thermoelectric cooler. The one concern with soldering is to minimize flux residue, as this can also outgas and contaminate the lens.

Heat Exchanger

Space constraints also have a negative impact on airflow, resulting in degraded performance of thermal-management solutions such as heat exchangers. More airflow ensures proper heat dissipation. For small packaged lasers, typically less than a 100- × 100-mm footprint, thermoelectric coolers are often mounted directly onto the exterior of the laser for temperature stabilization.

Thermoelectric coolers for laser cooling often have high heat pumping per square area, typically up to 13 W/cm2 to match the heat generated by the laser. Such coolers operating at these high heat-pumping levels often exceed the ability of a heatsink and fan to dissipate heat into the surrounding environment. A better option is an ambient liquid-cooling system and a cold plate, since this can minimize space constraints at the source, while routing heat out to an area where there’s more space to exhaust heat into the ambient environment.

Temperature Sensor

The location of temperature sensors play an important role in thermal management accuracy. Ideally, they should be located as close to the laser as possible to ensure precise temperature control and minimize offset reading from thermal resistances of materials between sensor and laser. However, space may be limited, so the thermistor (sensor) can be mounted on the cold block that mates to the laser. The thermal resistance between thermistor and laser can delay response time for closed-loop feedback.

Thermoelectric-Cooler Arrays

One or multiple thermoelectric coolers in an array can be used to pump heat. For multiple arrays, thermoelectric coolers should have lapped surfaces so that the thicknesses are within tight tolerances during mounting to a heat exchanger. This assures minimal air gap between the thermoelectric cooler and the heat exchanger.

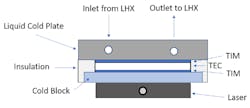

A laser projector’s thermoelectric cooler is normally mounted between a cold plate and a cold block (Fig. 2). Around the perimeter of the thermoelectric cooler is an insulation gasket. While the cold block is attached to the laser in the projector, the hot side of the thermoelectric cooler is attached to a cold plate that circulates coolant back to a liquid heat exchanger (LHX).

Comparing Cooling Technologies

Two common methods used to cool projection laser systems are compressor-based refrigeration systems such as chillers and an ambient liquid loop system that utilizes a thermoelectric cooler. Unlike liquid-to-air heat exchangers, both of these systems have the ability to cool well below ambient temperatures. Market leaders tend to use ambient liquid systems featuring a thermoelectric cooler, though, because they’re more cost-effective, reliable, and easier to design.

Compressor-based refrigeration systems offer a higher coefficient of performance (COP) compared to ambient liquid loops. Chillers operate via a compressor-based refrigeration unit that cools outbound fluid (coolant), which is then routed to the sensitive laser electronics to provide cooling. However, this closed-loop system loses some thermal control as it gets farther from the heat source.

Ambient liquid loops, on the other hand, use thermoelectric devices to provide precise spot-cooling of temperature-sensitive laser-projection components. Leveraging the Peltier effect, thermoelectric coolers actively dissipate heat away from sensitive electronics and cool well below ambient temperatures. Modern thermoelectric components utilize advanced thermoelectric materials for higher heat-pumping capacity compared to standard semiconductor materials.

Thermoelectric Cooling

Thermoelectric coolers offer high reliability, no operational noise levels, and perform well in high-vibration applications. Featuring no moving parts, solid-state thermoelectric coolers are almost maintenance-free, lowering the total ownership of laser-projection systems.

Thermoelectric coolers like the UltraTEC UTX Series (Fig. 3) feature a high heat-pumping capability up to 298 W with a maximum temperature differential (ΔT) of 72°C. As a result, they maintain stable temperatures of sensitive electronics below their maximum operating temperature.

In projection lasers, a large amount of heat travels through a very small area. The thermoelectric coolers that are typically used measure 25 × 25 mm, 30 × 30 mm, or 52 × 52 mm. For the larger heat-pumping models, it’s recommended to use a liquid heat exchanger on the hot side to dissipate heat into the surrounding environment.

Conclusion

To maximize the performance of high-power laser projectors employed in cinema and light shows, it’s vital to stabilize the operational temperature of laser optical components. Power densities continue to increase, improving illumination and color palette, while projector sizes continue to shrink, improving portability and installation options. Innovative cooling technologies are now able to support these design demands. Ambient liquid systems with thermoelectric coolers offer simplified spot-cooling to deliver precise temperature control, maintaining peak performance of the laser.

Because of its solid-state operation, thermoelectric coolers provide lower maintenance and longer life operation with no operational noise levels compared to other cooling solutions. The UltraTEC UTX Series thermoelectric cooler offers localized spot-cooling to provide superior temperature stabilization for lasers and optoelectronics. Thanks to advanced breakthroughs in materials sciences, this product series offers a 10% performance boost and a higher COP compared to standard thermoelectric coolers.

About the Author

Andrew Dereka

Product Director, Laird Thermal Systems

With more than 18 years of thermal experience, Andrew Dereka has served as the Thermoelectric Product Director at Laird Thermal Systems since 2015. Current and prior roles in sales and engineering provided deep market knowledge with expertise in a wide range of applications to help conceptualize and successfully implement thermal solutions for customers. Mr. Dereka has a MBA from Rutgers and a BSME from UNC Charlotte.