What’s the Difference Between Thermal-Interface Pads and Gels?

What you’ll learn:

- Key performance characteristics and differences between gap-filler pads and new advances in thermal gels.

- Pads and gels both transfer heat effectively, but which one is better for your specific application?

- At what volume of production might it be more cost-effective to automate with gels versus manually applying gap-filler pads.

Both pads and gels have proven to be effective means of thermal management in many industries and applications. While pads have a longer proven track record, recent advances in gels have closed the performance gap and, in some cases, surpassed that of pads.

Primer on the Role of Thermal-Interface Materials

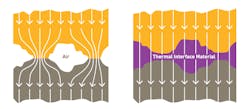

The objective of thermal management in electronics packaging is the efficient removal of heat from the semiconductor junction to the ambient environment. Thermally conductive materials are used to eliminate air gaps or voids from adjoining rough or uneven mating surfaces. Because the thermal-interface material has a greater thermal conductivity than the air it replaces, the resistance across the joint decreases, thus reducing the component junction temperature (Fig. 1).

When evaluating thermal-interface materials, design engineers seek to identify high-performance products that meet the thermal, design, manufacturing, and cost challenges inherent in each unique application.

What follows are ways that thermal-interface gels (or dispensable gap fillers) compare to gap pads in matters of critical importance to designers. Comparisons are organized by performance-based and manufacturing/packaging-based criteria:

Performance Characteristics

Conformability: Both gels and pads are conformable to a degree, but the maximum configurability of a gap pad is less than that of a gel due to a pad’s solid structure.

Flow rate: A goal when developing gels is to achieve the highest and most repeatable flow rate. Users want to be able to set their dispensing equipment for the same flow rate for all batches to maintain a consistent volume of dispensed material and avoid waste (Fig. 2). Newer gel technologies achieve a more repeatable and higher flow rate that improves throughput and reduces waste.

Thermal conductivity: Identifying the amount of heat (watts) in need of dissipation will determine the thermal conductivity performance needed from that application’s gap filler (Fig. 3). This is usually calculated and measured in watts per meter Kelvin, or W/m-K. The higher the value, the more heat the material can theoretically dissipate. Industry-wide, thermal conductivity of gap pads and gels can range from 1 to 10 W/m-K. In short, both pad and gel solutions are available to meet the thermal-conductivity requirements of most applications.

Long-term reliability: While this issue may require further research because of the newness of advanced gels, rigorous accelerated aging tests are being used to help assure long-term reliability.

Manufacturing/Packaging Characteristics

Automation: Gels hold a significant advantage in automation because dispensing systems are quite versatile. While pad placement can be automated to an extent, the equipment and fixturing required to do so is typically quite specialized and may not be readily adapted from one job to another.

Even with equipment programming time built into the setup cost, the process for automated dispensing of gels can be cost-efficient compared to the time required to design and produce pad-application tooling and the additional effort to then qualify the application process.

Throughput: While part production speed is application-dependent, to illustrate the potential advantage of gels, we will cite a specific customer example. This particular customer was considering a switch from pads to gels and ran a test of both materials to gauge the difference in throughput. Their study revealed that it required an operator 18 seconds to apply one pad, including handling the pad, placing it properly, and then moving on to the next component. Using a gel and an automated process, those same steps required only four seconds.

The argument favoring gels grows even more convincing if a single part has multiple dispense locations. An automated/robotic gel dispenser can hit each of the locations in one cycle, whereas with a gap pad, the operator would have to individually select and manually apply a pad to each part.

Ease of application: When placing a gap pad, the operator needs to know the pad’s orientation. There’s a top side and bottom side to the pad, and in many instances, there are also left-right and/or up-down orientations. Manual application introduces more risk for human error. With gel application, the metered gel is simply dispensed onto a specific location.

Precision: A benefit of the gap pad is that it can be cut to the exact shape of the component (Fig. 4), whereas the gel takes the shape of how it spreads out once compressed. The specific application will drive the degree of precision required, as well as determine the acceptability of whether the gel material extends beyond the surface of what it’s being applied to.

Shape complexity: The dispensed shape of a gel can help determine and control the ease of manufacturing and shape of the resulting spread (Fig. 5). For instance, a dollop or “Hershey’s kiss” type of shape is the simplest to dispense and will result in a roundish cross-section. An X-shape or serpentine dispense pattern results in a square cross-section at the expense of throughput. Very complex or thin shapes may not necessarily be well accommodated with die-cut gap pads; a gel may be able to better achieve those geometries.

Cost: In general, gels tend to be less expensive on a volume basis when comparing them with a gap pad product of a similar performance level (see tables below). Experience with multiple applications suggests that about 5,000 parts per year is the threshold where it becomes more economical to use gels and an automated dispensing system versus pads that are manually applied for the same application. Shape and geometry play heavily into that calculation, though.

Dispensing equipment investment can start at $10,000 to $30,000 for low-volume, tabletop units that require an operator. Increased sophistication and added features like camera recognition for quality control bring the equipment cost to $80,000 to $120,000 plus installation and training for a fully automated system.

Packaging: Pad packaging is essentially as complex as the customer part. A geometrically complex die-cut pad has costs associated with developing and producing the pad to that shape. However, there are other options if a customer wants to handle cutting the pad and/or has multiple shape requirements with a lower budget. For instance, pads are available in sheet form that can be readily cut or trimmed prior to application.

Gel packaging starts at 10-cc cartridges for manual dispensing, samples, or for very low-volume applications. Pneumatic-dispensed cartridges can range from 30-cc to 600-cc capacity. Those require simple dispensing equipment, which typically includes a high-pressure air line with a regulator and nozzle to connect it to the cartridge. An operator can dispense these gels by hand or there could be some type of robot-assist mechanism. One- to five-gallon pails support the highest throughput volumes and require a pneumatic pump to push the material into a secondary metering valve.

Final Considerations

As electronic design applications become smaller, more fragile, and more complex, thermal-management solutions are evolving with them. That’s what is happening with advances in thermal gels.

While gap-filler pads have long been the de facto choice for many design engineers, those engineers now can consider newer-generation gels. Recent advances in gel technology demonstrate that gels are able to provide superior performance, greater ease of manufacturing and assembly, and a lower cost in certain high-volume applications.