What Are the Benefits of First Article Inspection?

What you'll learn:

- What is first article inspection?

- At what points in the production process is first article inspection needed?

- What requirements are validated by the first article inspection process?

The first boards to come off the production line are the first article production units. First article inspection is a critically important step in the manufacturing process of PCB assemblies.

Need for a First Article Inspection

Inspecting the first article units during the early stage ensures that engineers or technicians have the requisite understanding and consideration of the customer’s requirements and incorporated them into their manufacturing processes.

The pressure of reaching the market early tends to compress design schedules. This rushes the process of designing a new PCB assembly, testing it, and getting it ready for production, which often leads to errors. Customers, therefore, approach contract manufacturers like Rush PCB, due to their understanding and appreciation of an approval process such as the first article. A first article inspection process helps to identify potential issues in the early stages, so that the customer can take corrective actions.

When is First Article Inspection Necessary?

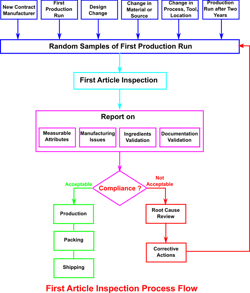

One must not confuse first article production units with pre-production samples or prototypes of PCB assemblies—these generally require different equipment and manufacturing processes. Moreover, first article PCB assemblies needn’t be the first units coming off a PCB assembly line. They can be random samples of the first production run.

Typically, a first article inspection is necessary:

- After changing a contract manufacturer

- After a first production run

- After a design change

- After a change in materials or source

- After a change in process, tool, or location

- After a couple of years of the last run

First Article Inspection—Two Purposes

The first article inspection process serves two important purposes. The first is to inspect and validate all documented requirements. The second is establishing the manufacturing Plan of Record or POR for the production line. Once the manufacturer establishes the POR, they must replicate it on an ongoing basis. This ensures the manufacturer meets documented requirements for all future production runs. It provides assurance that the manufacturer will build each board according to the same process and that each board will function identically.

The first article build process is meant not only for a new printed-circuit-board (PCB) design, but also when an existing design undergoes a revision. The manufacturer can’t change the POR unless the customer is revising the board. When a design is due for revision, the changes must be validated. At that point, it will be necessary to produce a new first article.

What First Article Inspection Validates

Inspecting first article PCB assembly units must be a thorough process (Fig. 1). It must validate all documented process requirements to ensure that they’re within specifications. Among others, the first article inspection process must aim for validation of:

- Measurable attributes: It’s necessary to measure, record, and verify all attributes mentioned by the covering design specification. Measurable attributes may include parameters like resistance, voltages, and dimensions.

- Manufacturing issues: Manufacturers must note down any problems, difficulties, or concerns they come across during the fabrication and assembly process. They have to examine these in consultation with the customer for changes and corrections.

- Ingredients: It’s necessary to verify all parts and materials used in the assembly process. These must match their specifications.

- Documentation: Identification of any confusion in documentation and clarification from the customer.

The above steps help to identify potential issues during the first article build. Identifying them before starting the PCB assembly production run allows for initiation of any corrective actions necessary. Implementing these before full production begins enables the production processes to proceed smoothly.

Parameters Affected

Depending on the results of the first article inspection process, the manufacturer may have to make adjustments to:

- Solder profiles

- Assembly process sequence

- Tools used

- Consumable materials

- Build documentation

- Test documentation

The first article inspection also may point to a source of problem based on the product design itself. In such as case the customer may have to initiate a design change and implement the corrective action necessary to correct the root cause of the problem.

First Article Inspection in Practice

Rush PCB has qualified assembly technicians that verify all components are matching the design and BOM supplied by the customer. Quality engineers inspect each step of the assembly stage, visually, through automated SPI, and through AOI machines to make sure placements of all components are perfect. A report is generated to corroborate the correctness of the PCB assembly, or if the equipment requires further adjustments. The board then goes for reflow soldering. The engineers look for any issues of solder-paste deposition and component placement, ensuring detection of any issues in settings and adjustments.

After soldering, the assembly undergoes visual inspection, X-ray inspection, and functional tests. A report from this stage points to any issues.

First article inspection provides an assessment of the quality level of the PCB before a full production run. This service should be one that all companies require when contracting PCB services to assure high-quality results.