Scalable, Ultra-Low-Latency MCUs Optimize Real-Time Control

Members can download this article in PDF format.

High-performance industrial and automotive applications require real-time control to quickly respond to sensor inputs—controlling an electromechanical actuator, for example, or adjusting the pulse widths of the output of a pulse-width modulator (PWM). Ultra-low-latency real-time microcontrollers (MCUs) are key components for such applications, providing the processing power necessary to make decisions and take action.

To speed your designs and reduce BOM costs, opt for real-time MCUs that include integrated data converters, flash memory, and configurable logic as well as flexible I/O interfaces. In addition, choose an MCU vendor that provides full support in the form of reference designs and software-development kits (SDKs).

Real-Time Signal Chain

Examples of real-time MCUs include members of the Texas Instruments C2000 portfolio. C2000 MCUs feature what the company calls a real-time signal chain, which minimizes the times between sensing and processing as well as the time between processing and control. To support sensing, the MCUs integrate digital-to-analog converters (DACs) and 12- or 16-bit analog-to-digital converters (ADCs) with post-processing capability.

To support processing, C2000 MCUs incorporate floating-point digital signal processing (DSP) in both single-core and multicore architectures optimized for complex mathematical real-time-control operations running at millions of instructions per second (MIPS). Most C2000 MCUs feature a control law accelerator (CLA), a 32-bit, floating-point math accelerator that aids in the concurrent processing of fast control algorithms.

For control, the final step in the real-time signal chain, the C2000 MCUs integrate flexible PWMs with resolution as low as 150 ps. This enables the high switching frequencies necessary to optimize designs employing silicon-carbide (SiC) and gallium-nitride (GaN) devices.

Built for ultra-low latency, C2000 MCUs come with integrated flash and a configurable logic block that helps minimize the need for external components such as FPGAs and complex programmable logic devices (CPLDs). Communication IP supports CAN-FD, LIN, and other interfaces to enable automotive and industrial applications.

In addition, TI’s Fast Serial Interface (FSI) facilitates reliable chip-to-chip communications at speeds to 200 Mb/s with skew compensation. To further support industrial and automotive applications, TI provides reference designs and application-specific software libraries to facilitate motor-control or digital-power designs.

Scalability and Compatibility

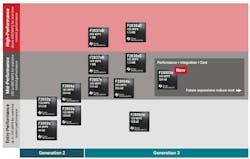

In addition to a real-time signal chain, scalability is a key feature for real-time power conversion for automotive and industrial applications. The traditional way to handle real-time control is to use a single centralized controller. However, consider the example of a multistage photovoltaic power system. Your centralized controller can run out of resources when you add stages to your system to achieve higher power levels.

As an alternative, you can employ a distributed architecture of compatible MCUs interconnected with FSI. A distributed architecture can provide the increasing levels of processing power (in MIPS) as well as the increasing numbers of PWMs and ADCs you will need as your application scales up. And you can accomplish this scalability without compromising on cost, complexity, and peripheral availability.

Figure 1 illustrates a distributed architecture for controlling the multiple power stages of a photovoltaic system. This implementation uses two C2000 MCU families. The entry-performance TMS320F28002x operates at 100 MIPS and features 12-bit ADC resolution as well as 14 PWM channels. The high-performance TMS320F2838x achieves 925 MIPS and features 12- and 16-bit ADC resolution as well as 32 PWM channels.

In the Figure 1 example, the F28002x MCUs control the dc-dc converter stages that implement maximum power-point tracking (MPPT), which optimizes photovoltaic panel efficiency over variations in irradiance, temperature, and other conditions. The F2838x MCU controls the inverter stage, which converts dc power to ac line power. The F28002x and F2838x are both members of the Generation 3 C2000 portfolio and therefore are code- and peripheral-compatible.

Efficiency and Cost Optimization

The newest addition to the Generation 3 C2000 real-time MCU portfolio is the TMS320F28003x family (Fig. 2), which enables high-efficiency real-time control while minimizing system costs. Family members can serve in electric- and hybrid-electric-vehicle systems and industrial motor-control and digital-power applications.

The F28003x features a 120-MHz DSP core with 240-MIPS processing capability to enable precise motor control and high switching speeds. An integrated CLA offloads tasks related to the execution of complex control algorithms. Device memory includes 384 kB of flash across three flash banks plus 69 kB of SRAM to enable fast control loops. In addition, 16 high-resolution PWM channels enable precise actuation and increased flexibility. Among the data-converter resources are three 12-bit 4-MSPS ADCs with post-processing and threshold capabilities, two 12-bit DACs, eight sigma-delta demodulation channels, and eight windowed comparators.

Digital peripheral options include integrated communications with CAN-FD and SCI, configurable logic block (CLB) tiles that augment existing peripheral capability, and high-speed communication with other TI devices using FSI. Functional safety-compliant MCUs offer support for ISO 26262 ASIL B functional-safety requirements.

Software support for the F28003x includes C2000Ware and two SDKs. C2000Ware features device-specific drivers and several libraries spanning math to security, such as a CLA math library and an AES encryption and decryption library.

In terms of SDKs, there’s the DigitalPower SDK. It’s a cohesive set of software infrastructure, tools, and documentation designed to minimize C2000 MCU-based, digital-power-system development time for various power converters and inverters targeting solar, telecom, server, electric-vehicle-charger, and industrial-power-delivery applications. In addition, the MotorControl SDK includes software infrastructure, tools, and documentation targeted for three-phase motor control in industrial applications. Both SDKs come with a copy of C2000Ware.

Conclusion

Electric cars, industrial motors, robotic arms, wind turbines, and photovoltaic inverters all require precise real-time control. Texas Instruments’ C2000 real-time MCUs have an optimized real-time signal chain that helps you reach your power and energy-efficiency goals for advanced industrial motor-control and digital-power designs as well as automotive applications. In addition, you can deploy C2000 MCUs in flexible distributed architectures that can scale with your evolving real-time-control requirements.