Industry 4.0 and IIoT: The Rise of Industrial Robots

What you'll learn:

- Reliability challenges due to the growing complexity of robots.

- Why non-volatile memory is a better option for data logging.

- Why many robot designers are moving to F-RAM as their preferred memory.

- Other storage-class memory options.

Part of the vision of Industry 4.0 is to combine smart sensors with industrial equipment to increase productivity, improve reliability, and lower operating costs. Many of these sensors will be connected wirelessly, either to each other (e.g., via a mesh configuration) or through a sensor gateway. This network will then be connected to the cloud where data can be collected, analyzed, and acted upon. The industrial Internet of Things (IIoT) differs from the Internet of Things in that devices must perform operations in real-time and meet industrial reliability standards.

Industrial robots are a special class of industrial equipment that perform manual tasks efficiently, accurately, and with repeatability. They have been used in commercial factories since the 1960s. With the advent of Industry 4.0, these robots are integrating intelligence and new capabilities that make smart factories possible.

In addition to being more flexible in the tasks they perform, industrial robots are able to collect and analyze data about themselves to improve productivity, quality of service, and reliability, all while lowering overall total cost of ownership. When connected to the cloud, operational patterns and trends across all robots can be identified.

For example, failures can be analyzed to create predictive-maintenance algorithms that trigger alerts when the operating profile of a robot resembles the profile of a similar robot that subsequently experienced a problem. The result is that issues are able to be addressed before they result in equipment failure and downtime, minimizing production losses.

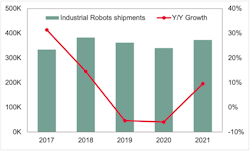

The ramp-up of industrial robots continues as more industrial automation OEMs invest in robotics technology. The robotics industry has grown at a rate of 7.6% annually (CAGR) since 2016, even taking into account declines in production associated with the global COVID-19 pandemic (Fig. 1).

Developers of industrial robots will face a litany of issues in the coming years. As these systems become more complex, it becomes increasingly important to be able to guarantee reliability. This article will explore the challenge of collecting operating data from industrial robots in the form of data logs, including how to handle the increasing amount of data that must be collected and how to minimize data loss during a system failure.

The Complexity of Industrial Robots

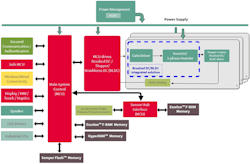

In its most basic form, an industrial robot consists of a manipulator and controller. The manipulator, often referred to as a robotic arm, moves, rotates, and perform actions. The controller actuates and controls the manipulator (Fig. 2).

The individual segments of each robotic manipulator are connected by mechanical joints, each of which provides an axis of movement. A typical manipulator has six movable joints or six axes of motion.

Each axis, moved by a high-precision servo or stepper motor, is limited to within a specific range of motion. In addition, each axis moves at a different velocity, often listed in datasheets as degrees traveled per second. The larger the range of motion and faster the top velocity of the joint, the higher the degree of accuracy that’s required to control movement. The need for greater coordination and precision also increases the amount of operational data that needs to be logged from each sensor tracking the manipulator.

From a reliability standpoint, industrial robots must be able to recover from a variety of power events, such as loss of power. Ideally, a robot can resume operations from exactly where it left off once the power event is resolved, even if the system was reset.

To achieve this, each motor must be able to save key parameters and data states, including the rotary angle and position of the arm. Similarly, the controller needs to maintain a detailed control log that records operational parameters of each axis, including its command position, encoder value, and payload.

Furthermore, the controller must maintain its own servomotor logs tracking speed, torque, motor feedback sensing (i.e., current, position, speed), and angle of movement. Reliably logging all of this data requires some form of non-volatile memory so that the data isn’t lost on power loss.

Non-Volatile Memory for Data Logging

In past decades, critical data has been held in battery-backed SRAM. However, this approach has numerous disadvantages:

- Several components are required (batteries, power management controller), consuming more PCB space as well as increasing the number of points of failure.

- To avoid exposing batteries to heat, batteries are typically mounted after the reflow process, increasing manufacturing cost.

- Industrial robots often are exposed to vibration, which can lead to mechanical failure of the connectors holding batteries in place, thus lowering overall reliability.

- Batteries require maintenance and replacement over the extended operating life of the typical industrial robot.

- Batteries don’t comply with RoHS requirements, introducing disposal issues for operators.

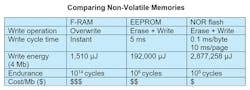

For these reasons and others, OEMs have turned to non-volatile memory devices to replace battery-backed SRAM. The table shows a selection of non-volatile memory technologies available to OEMs.

EEPROM can be eliminated as an option for most applications because of its low endurance. Industrial robots operate 24/7 and must log a tremendous amount of real-time data. Because these robots may operate continuously for many years, EEPROM will eventually wear down and therefore isn’t a viable choice.

Flash also has limited endurance. However, endurance issues for flash often can be addressed using wear-leveling techniques that are implemented in software on the host processor. When a block begins to experience errors beyond a set threshold, the wear-leveling algorithm moves data to a block that’s performing reliably.

Wear leveling is effective in increasing the usable life of memory by spreading wear evenly across the flash. However, the process of tracking and moving data throughout the memory comes at the expense of added complexity that loads the host CPU and introduces latency to write operations.

Perhaps the most important consideration when using flash for data logging is that it writes data in blocks. Log data must be collected in a buffer until an entire block is ready for writing. The wear-leveling algorithm, which can involve software-based lookup in large tables, then selects the block where the data should be written. Finally, flash must first erase the block before it can be written to.

Only after those tasks have been completed can the log data finally be written. All of these factors result in a relatively long delay between when the first bit of data in a block is captured and it’s actually stored in non-volatile memory.

Real-Time Reliability

As stated before, two of the primary reasons for data logging are performance analysis over time and power event recovery. For both functions, arguably the most important information is the data that’s collected at the time a failure occurs.

In the case of a power failure, the data will be used to recover and resume operation exactly where the industrial robot left off. For performance analysis, this “last moment” data is critical in understanding what happened just before the failure and what potentially caused the failure to occur.

When a system fails or a power event transpires, there’s little time to react. With flash and EEPROM, whatever is in the buffer will be lost. Yet this is the most important data. The longer it takes to write to memory, the greater the risk of losing crucial data. Consider a high-precision robot operating on an expensive part. If the robot experiences a power failure, the system needs to be able to reset back where it left off with a high degree of precision. Otherwise, the part may need to be scrapped.

To maintain operational parameters and a data log with high reliability, data must be captured and stored in non-volatile memory continuously. For this reason, robotic designers are moving to ferroelectric random-access memory (F-RAM). As can be seen from the table, F-RAM offers many advantages that make it a top choice for storing critical operational parameters and for data logging.

With an endurance of 1014 write cycles, F-RAM has effectively unlimited endurance for data-logging applications. In addition, no wear leveling is required, simplifying and lowering the latency of writes to memory.

Also impacting write speed is the fact that F-RAM is a random-access memory that doesn’t require an erase cycle. There’s no need to buffer blocks of data as data can stored in non-volatile memory immediately. Furthermore, the random-access nature of F-RAM eliminates latency delays that come with memory paging. When data is captured, it’s stored immediately.

Data-Logging Trends

Developers must make the decision whether to centralize data logging within the main controller or log data at the edge at each individual motor. Today, data-logging applications need up to 1 Mb at the motor, with controllers requiring up to 16 Mb.

For high-speed applications like a six-axis robotic controller, Infineon’s latest generation of non-volatile memories, Excelon F-RAM, provides higher density memory with a quad SPI interface to help speed throughput. For applications with smaller data-logging requirements, Excelon F-RAM comes in lower densities with a serial peripheral interface (SPI).

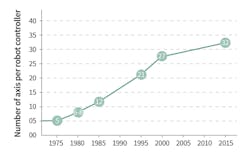

Data-logging requirements, however, are only going to expand as the number of axes and sensors in industrial robots continues to grow (Fig. 3). At the same time, AI-based performance and predictive-maintenance algorithms will need access to a wider range of parameters with higher granularity, increasing the overall amount of data that must be collected and stored.

Another trend that will impact non-volatile memory density is moving functionality out closer to the network edge. Implementing reliability and functional-safety features in each motor eliminates the latency of having to send data back to the main controller before making a response.

Many manufacturers are employing mini-controllers at each motor whose actions are coordinated by the main six-axis controller. Thus, each motor tracks its own parameters and sensors. This will, in turn, make it possible to move more advanced AI and machine-learning (ML) capabilities out to the edge as well to the individual motors.

Other Storage-Class Memories in Industrial Robots

In addition to data-logging memories, industrial robots employ a host of other memory technologies within the system, including storing the boot code as expansion memory. With the advent of Industry 4.0, there’s a surging need to protect systems from cyber threats.

One of the primary targets of hackers is the flash-memory device, which stores boot code, security keys, and other critical data pivotal to the proper system functionality. On that front, Infineon developed SEMPER Secure NOR Flash that’s compliant with functional-safety standards and has integrated security to protect code from being hacked.

The rising complexity of robotic controllers has led to many also having their own thin-film-transistor (TFT) display to support direct interaction with a technician in addition to being remotely controlled. For buffering data, audio, images, and video, or for use as a scratchpad for math and data-intensive operations, HyperRAM is a good fit as an expansion memory for industrial displays. It has throughputs of up to 800MB/s over a low-pin-count serial HyperBus interface.

Conclusion

Data logging is an essential feature in industrial robots, making it possible to recover from failures and power events without negatively impacting production. Data logging also plays an important role in enabling emerging AI and ML capabilities, such as predictive maintenance, by providing the data that will drive innovation in these applications.

The effectively unlimited endurance of F-RAM combined with its instant non-volatility, high throughput, and reliable data capture makes it a strong option for non-volatile memory targeting high-performance data logging in industrial robots. With the minimum loss of data during a power event, F-RAM makes it possible to perform even high-precision recovery in which a robot can continue operations exactly where it stopped before a reset or failure.

F-RAM is available in low and high densities to match the requirements of different applications. This also gives developers the flexibility to meet the evolving needs of next-generation robots as AI and ML capabilities move out closer to the edge.