Circuit Editing Evolves to Meet Semiconductor Needs

What you’ll learn:

- What circuit edit is and the financial and time-saving benefits in product development.

- Next-generation semiconductors and their potential impact on circuit edit.

- How advances in circuit-edit solutions can help address the challenges encountered by circuit-edit professionals.

In this Q&A, Editor Bill Wong talks with Thermo Fisher’s David Akerson, Senior Global Market Development Manager, about circuit edit and the strategic role it plays in advancing semiconductor product development and manufacturing

What is circuit editing?

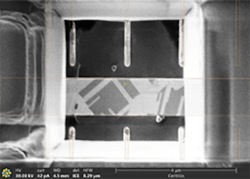

Circuit editing is a well-established technique that enables the direct repair of integrated-circuit (IC) defects. A precisely tuned and placed ion beam with nanoscale resolution, in conjunction with process gases, selectively uncovers internal circuitry, allowing a skilled focused-ion-beam (FIB) operator to make functional changes to the device or the copper wiring pattern. The FIB operator then reseals the chip surface to produce a functional device with revised circuit logic functions.

Why is FIB circuit editing important for semiconductor device development?

For IC developers, FIB circuit editing enables debugging and validating fixes, exploring design optimization changes, duplicating and scaling pre-production parts, and prototyping new devices without committing to the expense and lengthy delay of a mask spin. For many, circuit editing provides real tangible benefits that are quantified in cost savings, productivity, and time-to-market.

In terms of cost savings, the ability to rapidly prototype provides the ability to eliminate unnecessary wafer costs and schedule delays. With a full set of masks costing millions of dollars, the financial savings provided by circuit editing can be substantial.

There’s lots of pressure on the semiconductor industry right now. How does FIB circuit editing accelerate the time to market for a chip?

From a time-to-market perspective, the ability to quickly prototype enables internal and external development teams, or partners, to continue product and platform development without waiting six to eight weeks for wafer-processing time to get new samples.

Internally, the ability to rapidly prototype and deliver functional devices supports the efforts of the software and firmware development, testing, validation, and qualification, manufacturing process, and sales teams. This allows them to move projects forward and avoid schedule delays.

Externally, functional prototypes can support ecosystem enablement for key technologies and end-customer’s design-in and platform validation efforts. This helps fellow travelers hit their milestones and intercept market opportunities.

Logic architectures have evolved and increasingly become more complex. What are some common design and manufacturing challenges?

Each generation of architecture and fabrication process node advancement brings new challenges for semiconductor designers and circuit edit, as design and integration complexity increases.

For example, the introduction of FinFETs in 2011 on 22-nm processor nodes with new architectural structures, multi-patterning, and unique thermal and reliability behaviors brought a fundamental change to circuit editing. Where point-to-point wiring changes were scalable on planar FETs, the thinner, dielectric layer in FinFETs were more susceptible to transistor performance alterations.

For circuit editing, this necessitated the need for circuit-edit solutions with better aspect ratios for smaller cuts, higher resolutions, improved CAD navigation capabilities, and lower landing energies to keep the beam from penetrating and damaging sensitive circuits.

With new architectures, semiconductors are becoming more three-dimensional with higher aspect ratios, and more complex with smaller, more fragile features. The combination creates two new challenges—the need to to go deeper into the device and to carefully navigate around more delicate circuits. This dictates the need to “operate” in a more sensitive environment with a higher degree of surgical precision.

How are advances in circuit-editing technology helping semiconductor manufacturers overcome some of the current challenges associated with FIB circuit editing?

As semiconductors advance, circuit-edit solutions are advancing as well to meet the market’s needs. For example, as semiconductor manufacturers move to gate-all-around (GAA) FET architectures and 3D semiconductor packaging, new challenges have been encountered that require advances in circuit-edit tools.

To expand on this, GAAs feature a more complicated architecture that separates the transistor blocks, the interconnects, and power distribution. The GAA also includes wiring layers above the transistors, power rails below, and higher transistor densities.

With transistor layers, interconnects, and power distribution stacked on top of each other, a 3D high-aspect ratio structure is created, making it more challenging to access the active area at depth for circuit editing. With the higher number of transistors in a given area, this makes it easier to damage them.

As a result, GAA circuit editing requires a higher degree of precision and a higher level of control over the rate of the process. This translates into a need for circuit-edit tools with lower landing energies and beam currents than existed up until today.

Where many of today’s circuit-edit solutions operate at 1.2 pA, state-of-the-art circuit-edit solutions, such as the new Thermo Scientific Centrios HX, can operate at 0.33 pA. This lower landing energy and lower beam current reduces damage to sensitive circuits and allows the operator to remove very thin layers with surgical precision.

Aside from semiconductor device development, are there any other important applications where FIB circuit editing can be used?

When people hear the term “FIB circuit edit,” they tend to focus on the circuit-edit capabilities and don’t consider the FIB’s capabilities to go beyond. For example, with an advanced circuit-edit solution, the user has the sharpest scalpel in their toolbox with the ability to simultaneously capture high-resolution images and remove very small amounts of material in a controlled manner.

These characteristics make a circuit-edit solution attractive for other applications, such as deposition of semiconductors containing beam-sensitive transistors or materials, or for preparation of a device for failure analysis investigation.

What do you predict is next for the industry regarding circuit editing?

Going forward, many of the challenges encountered by IC designers will be similar in nature to those that occurred with previous inflection points. For instance, when semiconductors moved from planar to FinFETs, this created a need for circuit-edit tool improvements.

From a circuit-edit instrument perspective, as semiconductors evolve again, the device complexity places a greater premium on accurate ion beam positioning, and the ability to make precise, delicate cuts to access and service regions of interest. As a leader in providing circuit-edit instruments, these are areas we will continue to focus on to meet the semiconductor market’s needs.

For circuit-edit practitioners, it’s a very exciting time and we expect the circuit-edit function will continue to grow in strategic value. As devices and manufacturing processes become more complex with more steps, the probability of functional defects becomes higher. This makes circuit edit and the ability to deliver a functional device very valuable to an organization.