Download this article in PDF format.

The electronics industry is driven by a constant demand for smaller and more powerful devices. This means increased power densities and lots more heat being generated within ever-smaller spaces. As a result, the need for effective thermal design has become a vital part of the electronics engineering process.

It’s important that design engineers get the thermal design of their devices right the first time. For many, thermal issues are considered a low priority, primarily because thermal design is seen as a complex challenge—a hassle they could do without. How much of what you know about thermal management is fact vs. fiction, though? To find out, let’s explore 11 of the most common myths associated with thermal design.

1. It’s all about keeping things cool.

Wrong. While most engineers look to reduce the temperature of their products to avoid overheating, at its heart, thermal design is really about ensuring the optimum temperature to keep a device running efficiently. In some cases, this could simply mean ensuring a uniform temperature across all devices to ensure optimum performance. In others—particularly outdoor applications in cold climates—thermal engineers may even be looking to heat their products up!

2. Thermal design needs to be performed by mechanical engineers after electronics engineers finish their design.

While mechanical engineers obviously have a very strong knowledge of physics and thermal dynamics, which can help with temperature flow, the role of thermal design doesn’t have to lay exclusively at their door. At the end of the day, most engineers understand the role of temperature and (with the right tools) can work out if something is getting too hot. If engineers consider thermal issues in the very early stages of their designs, they can significantly reduce the number of costly thermal fixes further down the line.

3. Thermal design is not a priority.

According to 6SigmaET’s recent research, 40% of design engineers consider thermal design “low priority” when developing their devices. Instead, they listed their top priorities as ensuring product reliability, complying with regulations, and innovating new features. Of course, the irony of this is that accurate thermal design allows you to achieve all of these things.

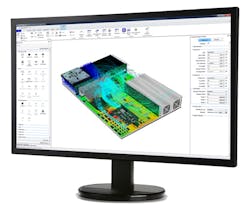

Here’s one view of Release 10 of 6SigmaET’s thermal simulation CAD system, which adds gap pads and substrates, and improved existing objects (e.g., power supply).

By stopping products from overheating, designers can ensure that their designs remain reliable and help to comply with strict safety regulations. At the same time, by cutting down on power consumption and space (e.g., designing out unnecessary fans), thermal design can free up opportunities for new components and innovations within an end product or design.

4. You have to develop a prototype to know if something is going to overheat.

Fortunately, this idea is becoming less prevalent. However, 6SigmaET’s research suggests that 1 in 10 design engineers still rely purely on physical prototypes to thermally test their designs. This not only prolongs the development process, but also significantly increases the total cost of product design.

While prototypes still have an important role to play in the design process, modern computer simulation is powerful enough to provide an accurate indication of where thermal issues are likely to occur, helping to hone measurements and reduce the number of required prototypes. For the optimum result, a combined approach should be taken, using both early-stage simulation and late-stage prototyping.

5. Everything can be fixed with a fan…

If a device appears to be overheating, one of the most common go-to solutions is simply to “stick an extra fan in there.” Unfortunately, as solutions go, this one can be counterintuitive. By adding a fan, designers often simply pile yet more components into an already over-packed casing. This not only adds to the bill of materials, but also increases the device’s energy consumption. At the same time, if the layout and airflow of a device hasn’t been designed for forced cooling beforehand, then adding a fan may not even deliver the necessary cooling for the components.

6. …or a heatsink.

A common fix for an overheating component is to put a heatsink on top. Actually the name heat “sink” is very misleading; in reality, they are “heat-moving devices” rather than tools specifically for heat absorption. The heatsink may cool the component it is sitting on, but it doesn’t just absorb the heat, it distributes it into the air around the heatsink. As with a fan, if a layout isn’t specifically designed with a heatsink in mind, adding one can create new unseen problems with getting hot air away from the component and out of the system (see #5 above).

7. Thermal simulations are complex and can only be conducted by experts.

As the process of thermal design has evolved, so too have the tools required to conduct and perform accurate thermal simulations. Previously, design engineers would have needed to develop models and simulation scenarios themselves. Now much of this work can be imported from CAD and automated within the software.

In addition, rather than investing in heavy-duty hardware to conduct such simulations, much of what was once processed on a local machine can now be exported to cloud-based servers for maximum solve speeds. These advances, combined with the improved user interfaces of modern simulation suites, have helped ensure that engineers don’t need an extensive knowledge to manage the heat flow of their designs.

8. Thermal simulation takes a long time.

Traditionally, thermal simulation has always been associated with slow build times and even slower solving. Thanks to enhancements in simulation tools, though, product specifications, PCB layouts, and CAD geometry can all be imported to a simulation suite—in standard formats—with ease. At the same time, significant advances in processing and solving technologies have also helped speed up simulation compute times. Thus, designs that would have once taken hours to simulate can now be computed in minutes.

This is another view of the 6SigmaET thermal-simulation modeling system.

9. Detailed thermal models are always better.

While many cases exist in which a highly detailed model will provide more accurate results, this isn’t always true. In fact, in some instances, a mathematically equivalent compact model is not only more efficient, but can provide results of an equal or even greater accuracy. One example would be in attempting to simulate a region of small holes or perforations.

Although it’s easy to generate the detailed geometry, the flow patterns in and around such small holes are incredibly complex. If this fine detail isn’t captured accurately, which requires a very large simulation model, the pressure drop across the perforations will be inaccurate. As such, in instances like these, additional complexity doesn’t always make a model more accurate. Instead, running a more general flow-resistance analysis may prove a far more effective option.

10. You need a very large and powerful computer to run thermal simulations and designs.

To be fair, this one has only recently become a myth. Typically speaking, thermal simulation does require a fairly hefty amount of processing power. As such, attempting to run a particularly large or detailed electronics simulation on a standard laptop could leave you waiting for days—or even weeks—for your end result to appear. Now, however, the advent of cloud computing has helped to cut processing times down to a fraction of what they were previously. By outsourcing the solving process to high-performance server clusters in the cloud, design engineers can run massively complex simulations without the need for a high-end local machine.

11. Thermal simulation tools are all the same.

In terms of the basic physics and flow phenomena, technically all thermal simulation software uses a very similar approach. That said, many of the tools on today’s market have remained largely unchanged for over 20 years. The logic behind this is that if the physical laws and equations related to heat flow haven’t changed, then why is there any need for the software to change?

This premise has resulted in a number of very outdated packages, many of which don’t provide the intuitive interfaces and levels of automation that today’s design engineers should expect. Rather than treating thermal simulation as a set-in-stone process, it’s worth shopping around for different tools to help decide which one is best suited to your project, device, or working style.