Download this article in PDF format.

Modern factories rely on computer networks to provide the communications between machine tools, programmable logic controllers (PLCs), robots, and other equipment. Sensors are connected to data-acquisition systems; sensors and actuators connect PLCs and other computers; and all equipment is further networked to larger factory or company computers, usually via Ethernet.

At the sensor and actuator level, fieldbuses provide some of the connections. However, more engineers are turning to another serial interface—IO-Link—for this purpose. This simple serial data standard and protocol is helping improve factory output and efficiency, with new IO-Link ICs delivering the desired operating performance.

Introduction to IO-Link

The next generation of factory manufacturing is referred to as Industry 4.0. Its goal is to create a smart factory that improves efficiency and performance, which largely hinges on communications between the computers, sensors, actuators and other equipment. A mix of networks is usually employed, including 4-to 20-mA current loops, HART, and IO-Link.

IO-Link is gaining popularity because it’s a simple, low-cost serial interface for sensors and actuators, and is backward-compatible with fieldbuses like Profibus, Profinet, and EtherCAT. When building new factories or retrofitting existing facilities, IO-Link becomes an excellent alternative. Here’s a summary of IO-Link facts and features:

- Developed by the IO-Link Consortium.

- Standardized by the International Electrotechnical Commission (IEC) as 61131-9.

- Point-to-point link between a sensor or actuator and a Master controller.

- Uses standard byte transfers that have common UART format with start, stop, and even parity bits.

- Typical data rates are 4.8, 38.4 or 230.4 kb/s.

- A Master controller initiates all access to the sensor or actuator.

- Data is transferred in multiple byte frames called telegrams.

- Common logic levels are binary 0 of 24 V and binary 1 of 0 V; NRZ encoding.

- Cabling is industry-standard 3-wire or 5-wire.

- Connectors are also industry-standard M5, M8, and M12.

- Cabling and connectors are fully compatible with all existing fieldbuses and other interfaces.

IO-Link: The Backbone of the Smart Factory

Simply put, IO-Link technology enables smarter factories for Industry 4.0. IO-Link delivers data to and from the factory floor to the plant level for factory efficiency, sensor diagnostics, maintenance, and other capabilities. With IO-Link, plant managers can easily receive sensor health updates and plan for upcoming sensor/actuator maintenance or replacement. And factory production lines can be upgraded to IO-Link with little effort. That’s because it’s backward-compatible to existing standard input/output (SIO) installations, and is able to use the existing 3-wire, unshielded cabling to minimize time and cost setup.

You may think that factories are already efficient based on the quality and price points of products you buy today. In reality, though, factories have numerous inefficiencies that an interface like IO-Link can help reduce. A few of the key advantages of IO-Link that help drive factory automation are discussed in this blog.

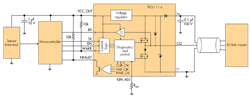

Here, the TIO111 transceiver has been integrated into a typical sensor-based IO-Link application.

IO-Link Integrated Circuits Make the Difference

IO-Link ICs are available from multiple vendors, but some of the most advanced have been developed by Texas Instruments. Consider the TIO111, an IO-Link transceiver that serves as the complete physical layer (PHY) for a network node. The figure shows a typical application. The sensor is commonly paired with a microcontroller (MCU). The MCU communicates with the TIO111 interface, which in turn connects to the Master controller via the standard cabling.

A couple of things to note: The dc power is delivered via the cable from the Master. It’s typically 24 V, but the TIO111 can operate from 7 to 36 V thanks to the built-in LDO regulator (3.3 or 5 V). Also consider the minimum number of external components—a couple of capacitors and a few resistors. The surge protection diodes are on-chip. A current-set resistor (RSET) allows you to adjust the current limit to any value between 50 and 350 mA.

Other features of the TIO111 include IEC 61000 standard protection: ±16-kV ESD, ±4-kV fast transient, ±1.2-kV/500-Ω surge current, and ±65-V transients; reverse-polarity protection; over-temperature warning and thermal protection; remote wakeup indicator; and a fault indicator. Temperature range is −40°C to 125°C. It’s packaged in a 2.5- by 3-mm, 10-pin VSON.

A companion IC, the TIO101, is a digital sensor output driver. It can accommodate capacitive or inductor sensors, or proximity switches or output actuators. The outputs may be configured as high-side, low-side, or push-pull. The device can drive large capacitive loads, otherwise the specs are similar to those of the TIO111.

Another device that’s available is the SN65HVI10x, a complete transceiver interface for implementing IO-Link nodes. Evaluation modules are provided for all of the above devices.

Product training for the IO-Link and the TIOL111 and TIOS101 ICs is available online in video form (click on the respective links). These videos introduce you to the IO-Link transceivers, and discuss features such as the full pin-to-pin compatibility between them.