Improving Factory Throughput and Efficiency with IO-Link

Download this article in PDF format.

One sure way to boost operational efficiency and factory throughput is to automate. Robots, special machines, programmable logic controllers (PLCs), and other equipment can usually do the jobs faster and at less cost.

The Industry 4.0 movement with its Internet of Things (IoT) component is proving that interconnecting the equipment as well as individual sensors and actuators delivers positive improvement in factory processes. Connecting this equipment and devices are multiple networks and fieldbuses. One technology that’s providing this wired connectivity right now at low cost is IO-Link.

Sponsored Resources:

- IO-Link Handbook

- Bring Your High-Current Sensors to the IO-Link Revolution

- MAX22513 Surge-Protected Dual Driver IO-Link Device Transceiver

An Introduction to IO-Link

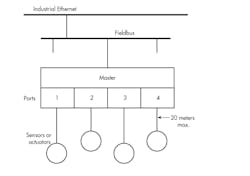

IO-Link is a simple network that consists of multiple devices connected directly to a master controller, much like that shown in Figure 1. Each machine, PLC, sensor, or controlled device gets a dedicated cable connected to the master control unit. The master control unit then usually connects to a fieldbus, and subsequently to another network like industrial Ethernet. IO-Link is also an international standard—IEC 61131-9—with multiple vendors and semiconductor companies supporting it. Check with the IO-Link Consortium for the latest information.

1. The architecture of an IO-Link system.

The IO-Link connections are made with standard three- or five-wire unshielded cables that carry the data as well as dc power if needed. The commonly used connectors are of the M5, M8 or M12 type. Figure 2 shows the basic connections. Maximum cable length is 20 meters depending on the application. These links support data rates of 4.8, 38.2, and 230.4 kb/s. Logic levels are binary 1 = 24 V, binary 0 = 0 V, or ground using non-return-to-zero (NRZ) encoding.

2. The popular M12 connector (device plugs) showing the electrical connections.

As for protocol, IO-Link uses the well-tested UART asynchronous byte transfer format with start, stop, and parity bits. The master control unit initiates all actions, interrogating the connected devices to determine status and the need to exchange data. Data is sent in frames of bytes designated as telegrams.

Implementing IO-Link

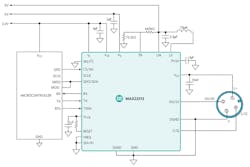

The heart of the master control unit and the devices being monitored (or controlled) is the transceiver. There are multi-vendors, but a good example is Maxim Integrated devices. Maxim is a leader in IO-Link sensor transceiver and master transceiver ICs. A representative transceiver is the company’s MAX22513, which can be used in the master controller ports for sensors or actuator devices. This transceiver is typically connected to an embedded microcontroller (MCU) that implements the transceiver functions and IO-Link protocol for input and output. Figure 3 shows the basic connections. This transceiver includes both I2C and SPI interfaces for connecting to the MCU.

3. The MAX22513 connects to an external MCU to form a complete transceiver for master controller ports and sensor/actuator IO.

The MAX22513 provides the full transceiver features with only a few external components. It includes a buck dc-dc converter that can be set to any voltage in the 2.5- to 12-V range and delivers up to 300 mA. The switching frequency is selectable. Two linear regulators are also on-chip to supply 3.3 and 5 V to external circuits and devices, like the MCU.

Multiple protection features are built into the MAX22513: the I/O pins have integrated 1-kV surge protection; overcurrent protection is selectable; and hot-plug and reverse-polarity protection are included. This tiny IC comes in a 28-pin TQFN-EP package (3.5 × 5.5 mm) and is available in a smaller WLP form. The target application for the device is industrial sensors.

In summary, the key benefits of the MAX22513 are:

- Easier and faster design thanks to high integration with surge protection and onboard regulators.

- Low power consumption.

- Small size matches the need for small sensors.

- Operates in a harsh factory environment.

An evaluation kit, the MAX22513EVKIT#, is available. And a reference design fully tested for ±1.2-kV/500-Ω surge protection, the MAXREFDES171#, is also available on Maxim's website.

A Focus on Sensors

The general consensus is that the more sensors, the better. By collecting more data and then analyzing it to make process decisions, all of the benefits of the Industry 4.0 effort will accrue—the factory becomes intelligent.

Industrial sensors have some tough requirements, including low power consumption, small size, and the ability to survive in a harsh factory environment. Some sensors will be wireless, but that brings on multiple problems. Foremost, complexity and reliability of the connection are major issues. With IO-Link, the system is simple and there’s nothing like a reliable cable to connect the sensor to the master controller.

Sensors are a sensible solution for factory automation. IO-Link enables traditional sensors to become intelligent sensors. And that, in turn, provides the flexible manufacturing processes to improve factory throughput and operational efficiency.

Accessories

Maxim also provides a few support IC that fit some use cases and help reduce the amount of complexity and size of the end product:

- MAX22190/2 digital input devices with eight channels.

- MAX14914ATE, a high-side switch IC for switching external loads like motors.

If you’re contemplating a design with IO-Link, Maxim’s Go-IO reference design will be of interest. It’s a platform for rapid prototyping and development of configurable industrial control systems. It includes a four-port IO Link master that’s 1.1 compliant. One key feature is an RS-485 interface for connection to a fieldbus or other network. All major IO lines include integrated ESD and surge protection.

If you’re working on products for Industry 4.0 or IoT products, the devices described here can help you speed up and simplify development. Take a look.

Sponsored Resources: