Watches that provide heart-rate monitoring look similar look to their analog or mechanical counterparts. All of these devices have familiar watch faces and wrist bands. However, inside the digital watch are key electronic components that make heart-rate measurement possible: a photoplethysmography (PPG) sensor and an accelerometer.

The PPG sensor (photodiode) measures light-intensity fluctuation caused by blood volume changes. As the heart pumps out blood from the left ventricle, blood rushes through the smaller blood vessels. As blood vessels expand to accommodate the sudden increase in blood volume, light intensity reflected from the blood is increased and a photodiode sensor captures this light-intensity change. This is essentially how a PPG sensor works.

However, a PPG sensor faces challenges in providing accurate heart-rate detection, and these challenges can be affected by the industrial design of the wearable. This article will discuss these challenges and highlight how proper industrial design of wearable devices can contribute to accurate heart-rate monitoring.

Challenges

One of the big issues facing a PPG sensor is that, during active body motion like running, the sensor also senses the motion-related blood volume change in the wrist as the wrist-worn watch presses the skin and deforms the blood vessel under the skin. Therefore, the PPG sensor senses the reflected light-intensity change in the blood-volume change as it stems from motion as well as from cardiac origins. The accelerometer cancels out motion-related PPG from the total PPG measurement.

Information from the accelerometer teaches a PPG processing algorithm which frequency component stems from motion and which frequency component comes from the heartbeat. The very nature of the 3D accelerometer also allows us to classify the types of motion. This information enables the device to detect heart rate correctly. While heart-rate detection from a PPG sensor isn’t as simple a task as noise cancellation done in time series by the least square minimization method, we can think of similar logic in the frequency domain in a wearable watch’s algorithm.

Another source of confusion in heart-rate detection via PPG is LED scattering. When there’s repetitive arm motion during an activity like running, badly designed wearable watches allow an air gap between the photodiode and the skin, which may cause scattering. Repetitive scattering can easily degrade a cardiac-related PPG component from the spectrum, making it difficult to distinguish our interested cardiac signal from the motion artifact.

Enhancing Accuracy of Heart-Rate Monitoring

Proper industrial design (ID) of wrist-based wearables provides a route toward achieving more accurate heart-rate monitoring results (regardless of the effects of motion).

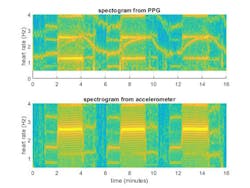

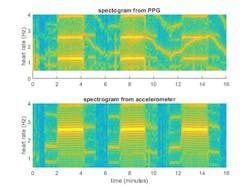

Let’s look at two spectrograms: Figure 1 is the spectrogram from an optimized ID, while Figure 2 shows a badly designed watch. To generate these spectrograms, PPG and a synchronized accelerometer signal were collected during treadmill running and slow walking. Heart rate goes up during running and goes down during slow walking (thus, the sine-wave-like pattern).

As mentioned earlier, the spectrogram from the PPG signal (top) has both the heart-rate-induced pattern and motion-related pattern (rectangular pulse). If the wrist-worn watch is well designed, it should show the spectrogram as depicted in Figure 1.

1. The spectrograms show the ower spectrum density of the PPG and accelerometer from a watch with an optimal industrial design. The subject in this test repeated periods of slow walking and running three times. Heart-rate frequency is clearly visible during all epochs of running and easily separable from motion frequency.

In Figure 1, the PPG reading clearly shows distinct frequency in both heart rate and motion, and these two can be easily separated from a visual standpoint. However, in Figure 2, in two periods of running, the spectrogram of the PPG signal shows that heart rate isn’t visible. When the user wears the watch too tightly and the watch presses the blood bed under the skin, blood perfusion is decreased enough to smear the distinct heart-rate-related PPG reading. This is what happened in Figure 2, where the PPG reading bears a strong spectrum of motion rather than heart rate, making it difficult to separate heart-rate frequency from motion frequency.

2. These spectrograms reveal the power spectrum density of the PPG and accelerometer from a badly designed watch. The subject in this test repeated periods of slow walking and running three times. On the first and second run, the heart-rate component of PPG wasn’t detectable due to the strong motion registered in the PPG reading.

As this example showed, it’s essential to optimize the mesa area and height to minimize the motion effect and still allow the blood flow to fluctuate. We can achieve this goal by optimizing the mesa dimension and components’ weight distribution within the watch case, which would decrease this rocking behavior during motion. Here are various characteristics of ID we can consider:

- Mesa (raised well housing photodiode sensor in contact with skin; Figure 3)

- Optical distance between LED light source and photodiode

- Wristband

- Component weight distribution

3. The mesa, which is the raised well that houses the photodiode sensor, is located on the back of a wrist-worn watch.

Mesa: Addressing Height and Curvature to Minimize Ambient Light

In ID, the mesa is a raised well housing the optical photodiode and light source in close contact with the skin. The height and curvature dimension of the mesa will be essential in minimizing the ambient light getting into the photodiode sensor. The ideal situation is to maintain good skin contact during motion, which would minimize the effects of ambient light sources such as sun or fluorescent light. A light source such as the sun is strong enough to wipe out the PPG signal as well as add alternating intensity of light caused by arm motion to the photodiode sensor.

Some PPG sensors, such as Maxim’s MAX30100, have a built-in ambient cancellation circuit called picket-fence cancellation to address mixed light situations such as sun and shade. But, still, minimizing the effects of ambient light in the ID stage is a good idea. Fluorescent light sources can cause 50/60-Hz flickering light intensity on the PPG signal. Arm movement of the runner can easily add 2-Hz motion artifact noise, which could be mistakenly construed as 120 bpm of heart rate.

The area of mesa protrusion is another important factor in maintaining steady blood perfusion during motion by distributing sudden rocking pressure gently across an area of skin. By distributing this pressure evenly and decreasing external pressure to the skin, the wearable watch can maintain blood perfusion near the LED light source and sensor, enabling it to measure a good-quality PPG signal.

Optical Distance Between LED Light Source and Photodiode

The distance between the light source and photodiode in the mesa is another factor determining light-source intensity (battery life!) and signal quality. If the distance is too short, the photodiode may not receive reflected light from the blood; if it’s too far, the reflected light energy becomes too weak, lowering the signal-to-noise ratio (SNR).

Blindly increasing the LED current might saturate the photodiode output, which may not provide the salient information necessary for heart-rate detection.

Wristband Considerations

The material and tactile quality of the wristband are important factors to consider when trying to minimize the effect of motion to the PPG sensed at the photodiode light sensor while the user is running.

Fabric impregnated with elastic material would cause friction between the band and the wrist, hampering the watch’s rotation around the wrist. A snuggly fit elastic band, on the other hand, would maintain the consistent distance between the watch mesa and skin, decreasing the effect of motion artifacts.

Ideally, a wearable watch should stay on the same spot where blood perfuses well, and the distance between the watch and the optics should be maintained on the same optical path. Any circumstances violating this can be resolved through advanced algorithms that extract heart rate correctly.

Component Weight Distribution Within Case

An often-ignored factor in designing a wearable watch is the distribution of its components’ weight, which is essential for decreasing the wearable’s rocking motion. Watch users tend to like scratch-resistant watch faces, yet the manufacturer’s preference for scratch-resistant glass often exacerbates this very rocking motion because the heavier glass moves on top of all the other watch components. Thus, the industrial designer and component designer need to work together to avoid this top-heavy weight distribution.

Summary

Delivering accurate heart-rate monitoring from wrist-based wearables such as watches is no easy feat, because the heart-rate signal of interest is often corrupted by arm and hand motion. This motion-related noise is nonlinear in nature and can’t be cancelled out by well-established time-domain automatic-noise-cancellation (ANC) algorithms. Furthermore, frequency-domain computation is too costly in a power-stingy wearable platform.

Thus, it’s essential to find a compromise that will minimize motion-related artifacts. Addressing these challenges at the ID stage, in a way that minimizes required algorithmic computations, provides an effective way to achieve accurate heart-rate detection from wearables even in the presence of motion.

Steve Koh is Principal Member of Technical Service, Industrial & Healthcare Business Unit, at Maxim Integrated.