Solid-State Sensor for ADAS, Autonomous Driving Targets $500 Price Point

What you’ll learn:

- How the H800 solid-state LiDAR sensor can meet ADAS Level 2 to Level 5 for autonomous applications.

- How Velodyne meets the $500 price point.

- How good is the H800 sensor’s field of view and range?

Velodyne Lidar’s latest product, the Velarray H800, is a solid-state sensor designed for automotive navigation and collision avoidance in advanced driver-assistance systems (ADAS) and self-driving vehicles. Built using Velodyne's micro-LiDAR array (MLA) architecture, it employs eight emitting lasers, photodetectors, and a proprietary ASIC chip, all of which fit into a package about the size of a postage stamp.

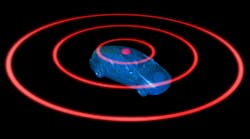

Light detection and ranging (LiDAR) is a sensor technology that enables autonomous vehicles to “see” the surrounding world, creating a virtual model of the environment to facilitate decision-making and navigation. A LiDAR sensor creates a 3D map of the surrounding environment by using scanning laser beams and time-of-flight (ToF) distance measurements. ToF, which is LiDAR’s operational principle, provides distance information by measuring the travel time of emitted light. Reflected light signals are measured and processed by the vehicle to detect, identify, and decide how to interact with or avoid objects.

Earlier iterations of self-driving car LiDARs were electromechanical and mounted on bases that rotated mechanically to emit laser light in 360 degrees. The laser and collector rotated to scan the area around it. These moving parts had to be precise to obtain measurements suitable for autonomous navigation. In addition, moving parts meant that the sensor would be less resilient to vibrations. Driving in rough terrain, for example, could negatively impact measurements.

Solid-state LiDARs are sensors based on a silicon chip and don’t require mechanically moving parts. The benefits of the solid-state construction are reflected in reduced construction space, allowing suppliers to cut costs and reach extremely small dimensions so that the units can be integrated into vehicles. Its form factor means that the Velarray H800 is suitable for interior and exterior applications and can be integrated by OEM designers and engineers with greater design freedom and flexibility.

Solid-State Advantages

Solid-state LiDAR can provide increased range and resolution. This precision, combined with long-range detection, results in better classification of objects (e.g., pedestrians and vehicles) and improved movement tracking—how fast an object is moving and in which direction.

A solid-state design has another advantage: With no moving parts, the sensor is inherently less complex and fragile than other designs that rely on micro-mechanical spinning mirrors or other physical scanning mechanisms.

Because it has no moving parts, a solid-state device is resistant to shock and vibration and thus is less prone to motion-related inaccuracy. Solid-state LiDAR also can provide accurate 3D imaging in any weather, independent of day or night.

Such capabilities are possible thanks to a concept similar to phased-array radar, in which several optical emitters send out bursts of photons in specific patterns and phases to create a directional emission. The size, focus, and direction of this broadcast can be changed without having to physically adjust the transmitters.

Velarray Features

With a field of view of 120 degrees horizontally and 16 degrees vertically, the Velarray H800 enables detection of objects in the periphery, in the near-field, and overhead, while at the same time handling curves on sloping and winding roads. This enables advanced highway ADAS features such as adaptive cruise control, lane keep assist, and automatic emergency braking. The sensor can be coupled with the Vella software suite from Velodyne, which covers the entire spectrum of safety functions.

These hardware and software components are being developed to comply with the automotive functional safety requirements defined within the ISO-26262 standard. Through predictive collision monitoring, Vella compares an object’s trajectory with that of another vehicle in order to identify and avoid imminent crash scenarios.

The Velarray H800 delivers detection data at a functioning range of between 0.1 and 200 m. This range combined with its relatively wide field of view means that corners and sloping roads are within the Velarray H800’s sensing range. As a result, it can detect objects early enough to enable safe stopping distances in urban driving scenarios and collision avoidance on curves and turns.

With a configurable frame rate, the Velarray H800 offers the high point-cloud density required for high-resolution mapping and object classification tasks. Point clouds are usually formed by a large amount of data. Newer, intelligent LiDAR systems such as this can revisit an object within the same frame—they have the ability to query an object or position multiple times within a conventional frame.

The first new sensor from Velodyne launched since the company went public on September 30, the Velarray H800 kicks off the next generation of the company's solid-state LiDAR portfolio with more announcements due in coming months.

The sensor is the focal point of the company’s efforts to make LiDAR technology widely available at a more affordable price point. Velodyne Lidar has announced plans to bring sensors for driverless cars into mass production in 2021—with a target price of USD $500.

Competition on the Solid-State Sensor Front

Velodyne is facing competition in this arena: Ouster’s ES2 sensor, announced in October, uses electronic scanning to sequentially fire an array of over 10,000 lasers printed onto a single chip, each fixed on a different point in the field of view. No moving parts are required to reach the range, field of view, and resolution targets of high-performance autonomy.

Ouster’s ES2 sensor will debut with a maximum range of over 200 meters on a 10% reflective surface. The company plans to aggressively bring down the cost of solid-state LiDAR; the ES2 will carry an expected price of $600 in series production. Its roadmap is said to allow future models to break the $100 price barrier.

Development of the ES2 sensor is underway at Ouster’s San Francisco headquarters, and the firm plans to deliver samples of the product to key customers and partners in 2022. Volume production will commence in 2023 and series production in 2024.

Innoviz is one of the first LiDAR companies to develop perception software, which will accompany its InnovizOne sensor for automotive-grade applications. The sensor uses a microelectromechanical-system (MEMS) mirror to steer the beam coming from stationary lasers. InnovizOne will be used in the upcoming iX all-electric SUV from BMW as well as for the mass-production of Level 3-5 autonomous vehicles.

Volvo intends to use startup Luminar’s LiDAR sensors in its upcoming XC90 in 2022. Luminar has said its LiDAR unit will cost less than $1,000 per unit for production vehicles seeking full autonomy and about $500 for version used for more limited purposes like driver assistance.

In all, analysts at the technology consulting firm IDTechEx are tracking more than 100 companies that are currently developing 3D LiDAR modules.