The Role of Centralized Storage in the Emerging Interactive Cockpit

Download this article in PDF format.

What you’ll learn:

- Why centralized storage is critical to enabling an interactive vehicle cockpit.

- The drawbacks of traditional in-vehicle infotainment (IVI) systems.

- How mobility is influencing vehicle cockpit design.

The automotive industry is going through one of the most significant transformations since the invention of vehicles themselves. Today, vehicle ownership in many cities is increasingly becoming optional rather than mandatory. Manufacturers have adjusted their offerings to appeal to a buyer’s lifestyle. Now, and in the future, the cockpit experience is central to achieving this goal.

Traditionally, brands have differentiated themselves based on powertrain features, styling, and most recently, the in-cabin experience. For the past decade, the in-cabin experience has been defined by the in-vehicle infotainment (IVI) system. These have evolved from multi-source entertainment, navigation, and personal-device integration systems to a fully connected experience. Buyers have been able to create a certain level of personalization based on menu-driven selections, speech recognition, text-to-speech, and more.

One of the more recent achievements of in-vehicle systems has been creating a seamless experience for users. Case in point: the integration of Apple and Android devices has become an expectation.

With tech-enabled features and functionality in vehicles on the rise, consumers are increasingly shopping for their new vehicles more like smartphones and tablets, They’re weighing up digital features like personalization, displays, in-vehicle connectivity, and infotainment, rather than horsepower, torque, make, model, and design. To keep pace with these evolving expectations, automotive memory and storage, speed of access, and rich data sharing will all become more critical for powering the next generation of connected vehicles.

Traditional IVI Systems Have Their Drawbacks

The architecture of IVI systems typically has been isolated. A recent example includes integration of the instrument cluster information bridge into the same assembly known as a domain controller. The domain controller was created to offer a cost reduction from a freestanding cluster and IVI system as well as to begin to create information sharing between the two primary driver interfaces. Most of these devices are based on a single multicore system-on-chip (SoC) processor.

The architecture is divided into two domains, one being isolated for the safety-critical interface to the instrument cluster. This domain is usually certified under the Automotive Safety Integrity Level Class B (ASIL-B). Where connectivity is present, this function is enabled separately by a telematics control unit (TCU) that’s often isolated with a secure gateway.

Despite the genuine efforts to offer a compelling user experience, these systems haven’t been able to keep pace with the level of innovation that consumers expect—which are primarily driven by their smartphone experiences outside of the vehicle. The one key challenge has been the inability to reconfigure and update the system after the vehicle is in the field.

That’s all starting to change. Audi recently announced a revised IVI system for its 2021 models. In response to consumer concerns about sluggish performance compared to their smartphones, Audi now uses a hardware platform that’s 10 times faster than its previous generation. The new system also features over-the-air enhancements that can be downloaded throughout the life of the vehicle. This can include an array of personalized streaming content and unlimited Wi-Fi connectivity over a 1-GB/s LTE advanced modem. It’s an obvious move to bring the in-car experience closer to what’s available from today’s consumer electronics.

The Influence of Mobility on Cockpit Design

Recognizing changing consumer culture around vehicle usage and ownership, we will soon migrate between owned, shared, and mobility fleet vehicles. The industry has recognized the need for a mobile persona and is now developing the next-generation vehicle cockpit systems to accommodate them.

Cockpits serve several fundamental needs. They identify users, often from a fleet population, onboard and protect their personal preferences, content access, and commercial/financial profiles; determine where they sit in the vehicle; deliver an interactive experience to a person individually in a seated location; deliver multiple experiences simultaneously; isolate that user from other passengers in the vehicle, where possible; and delete or isolate a users’ profile when not in the vehicle.

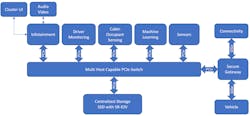

We assume vehicles will be part of a mobility fleet. Additional information about the vehicle itself must be stored, maintained, and interact with the centralized mobility service (Fig. 1). This includes data about cybersecurity and vehicle security, remote diagnostics, predictive maintenance, vehicle health check, customer connectivity and patterns, navigation, etc.

To keep the vehicle updated and secure, a number of attributes about the vehicle will likely be stored on the vehicle to enable secure update strategies (Fig. 2). Among them are mobility microservices, open APIs, digital assistant profiles, AI/ML engine interface, telematics IP configuration, and more.

The Interactive Cockpit Domain Controller

Vehicle manufacturers are currently developing cockpit domain platforms intended to provide a level of functionality that maximizes the user experience for all passengers, creates secure personal mobile identity and profiling, enables mobility services within a fleet, and maintains fleet integrity and security while allowing an ongoing refresh of features and functionality over the life of the vehicle.

These controllers will utilize multimodal user identification, such as speech recognition, facial recognition, biometrics, spatial telemetry for occupant location, multiple instantiations of interactive services like entertainment, IoT interaction, and more. Profiles for users, vehicle identity/status, local content storage, etc. are creating the need for overall storage approaching 1 TB.

The controller will consist of several subsystems, including vision systems; multi-source connected entertainment; audio capture systems; an AI accelerator; a connectivity gateway; security infrastructure, and more. With so many subsystems, data ideally needs to be shared between all of these to create a well-integrated solution (Fig. 3). Although there’s a high volume of data exchange within the system, a user expects the system will behave with minimal latency. As an engineer, we also can’t forget system cost! It’s paramount to maximize design efficiency as lower cost translates to higher fit rates.

From a data infrastructure standpoint, key system requirements include six elements:

- Data-transfer speed

- Ability to share data between multiple subsystems on one SoC or multiple dissimilar SoCs

- Ability to isolate processes to ensure design safety and security goals

- Ability to encrypt sensitive data where applicable

- Ability to securely update or remotely exchange vehicle profiles and stored data

- Eliminate system redundancies to optimize cost

These attributes, at a minimum, point to a centralized NVMe/PCIe storage solution as an advantageous design direction for this architecture.

The Benefits of a Centralized NVMe/PCIe Storage Solution

The performance of a UFS-based storage solution compared to a PCIe-based storage solution is shown in Figure 4. Storage solutions based on the Universal Flash Storage (UFS) interface have been popular for automotive IVI applications as the auto industry typically adopts SoCs originally designed for mobile phones in automobiles.

In smartphones, UFS has established a dominance as the successor to storage based on eMMC. However, as shown in Figure 4, PCIe-based solutions significantly outperform UFS-based storage solutions in both sequential and random read and write performance and, as such, are now seeing strong adoption in next-generation automotive IVI platforms.

With the introduction of PCIe-based storage solutions, it’s likely these systems will utilize a PCIe backbone to integrate sensor fusion and action, much like an ADAS system, but for the cockpit. System responsiveness is paramount and a PCIe backbone offers data bandwidth of 2 GB/s per lane (8 GB/s for four lanes).

For data storage and access, the PCIe interface offers the highest data-transfer speed amongst storage solutions. Automotive-grade solid-state drives (SSDs) based on NVMe architecture are well-suited to this need, offering data-transfer speeds of 3 to 4 GB/s. The PCIe interface protocol also is far more efficient than other interfaces, offering additional low-latency benefits when compared to UFS.

Sharing Data Between Multiple Subsystems on One SoC or Multiple Dissimilar SoCs

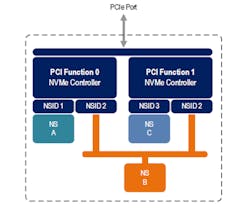

An automotive-grade SSD based on NVMe standards utilizes multiple namespace configurations. Namespaces are unique data storage areas that may be privately (namespaces A and C in Fig. 5) or publicly (namespace B) accessible. Data that’s intended to be shared between processes or subsystems can be defined as a public namespace for that purpose.

Isolating Processes to Ensure Design Safety and Security Goals

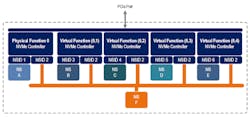

It can also use industry-recognized hardware-based isolation based on single root I/O virtualization (SR-IOV) (Fig. 6). This technology allows the system’s PCIe interface to be subdivided into multiple virtual machines running on the SoC environment that are isolated from one another and each tied to unique virtual functions on the storage device. This technique is well-recognized as a secure isolation method.

SR-IOV offers an additional benefit of establishing direct connection between stored data and the active process in runtime. This eliminates the need for a system scheduler, such as a hypervisor, which leads to improved system speed and reduced latency. Again, this is a benefit to the user experience and system efficiency.

Furthermore, the technology offers the ability to encrypt sensitive data stored on the drive, such as vehicle firmware, personal identity information, whitelist/blacklist security profiles, and more (Fig. 7). Encryption is protected by symmetric private keys.

Aside from encryption capabilities, these devices offer cryptographically protected access control to data regions. Such features deliver strong benefits not just to the vehicle platform, but also to the overall connected infrastructure interacting with the vehicle. Automotive-grade SSDs based on the NVMe standard use cryptographic access control to the overall drive. This feature protects the drive from unauthorized access. Certain keys are used within the system to bind the physical drive to the system architecture and various components to minimize direct security threats.

On top of that, the standard utilizes additional keys that are part of an overall remote security strategy allowing for remote re-provisioning of the storage device by authorized sources while protecting stored data. In a catastrophic event, it’s possible to wipe all or a portion of the drive by remote authorization. This is one of the many features that help enable proactive and timely fleet management with requisite security.

In the past, traditional architectures had a unique individual storage subsystem associated with each function. It should be clear by the benefits described here that none of the system-level benefits would be possible without a centralized storage architecture and a storage solution based on an automotive-grade SSD PCIe/NVMe device.

Automotive SSDs with SR-IOV features are available in densities ranging from 128 GB to over 1 TB, and they’re cost-competitive with other storage devices such as UFS in similar densities. The array of beneficial features of NVMe-based SSDs are available with minimal additional cost.

By utilizing a single storage device, storage cost and required PCB area are minimized versus multiple discrete storage entities.

The Benefits of Centralized Storage in IVI Systems

Centralized storage is necessary to enable data sharing between functional systems. It’s also fundamental in creating the interactive and personalized user experience that consumers want in their vehicles. An automotive-grade SSD offers a rich set of features including high speed, functional data isolation, cryptographic data protection, secure remote re-provisioning, and much more at a price-per-density like more isolated storage devices (e.g., UFS). Aside from eliminating design redundancy, SSDs require little PCB area since they’re available in small-form-factor ball-grid-array (BGA) packages.

The solution benefits of centralized storage and automotive-grade SSDs discussed here are being applied to next-generation architectures for 2023 and beyond. And not only for IVI, but also for automated driving and central compute architectures at key automotive OEMs and partners.

About the Author

Michael Burk

Principal Architect, Micron Technology

Michael Burk is principal architect for in-vehicle infotainment systems within Micron Technology’s Embedded Business Unit, which encompasses Micron’s automotive solutions. He holds a degree in electrical engineering from Purdue University.

Mr. Burk’s automotive industry experience spans 48 years. Prior to joining Micron in 2018, he was chief engineer of advanced development for Panasonic Automotive for 18 years. Prior to that, he was director of audio system engineering for Harman. Mr. Burk also was a partner in a successful aftermarket speaker company for over 20 years and was a key contributor to the early automotive aftermarket.