Electric Highway Tests Accelerate in Germany and the UK

What you'll learn:

- Steps being taken to develop overhead electrification on the highway for trucks.

- The roles played by catenaries and pantographs.

- How much more power/battery efficiency is delivered by overhead contact lines?

Modern electric locomotives use brushless three-phase ac induction motors. High voltage is employed because this allows the use of low current. Transformers in the locomotives transform this power to lower voltage and higher current for the motors.

Similar to an electric vehicle (EV), electric traction allows for the use of regenerative braking. The motors are used as brakes and become generators that transform the motion of the train into electrical power, which is then fed back into the lines.

Railways (as well as streetcars or light rail vehicles) generally use a system of overhead wires called catenaries to supply electricity to a locomotive that’s equipped with a pantograph collector sitting on the roof. These wires supply the positive and negative electrical circuit that’s picked up through the pantograph collector. A pantograph is a hinged frame that holds the collecting shoes against the wire in a fixed geometry.

Overhead Electrification

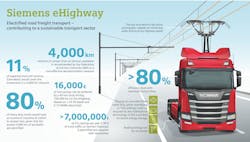

Siemens Mobility wants to apply the principle of overhead electrification to the highway. Approximately 24% of global CO2 emissions are caused by transportation, and road freight transport plays a considerable role in these emissions. By electrifying key sections of the highway network (eHighway) with an overhead line system, the company says it can significantly reduce CO2 emissions from trucks in line with EU regulation 2019/1242.

The eHighway technology will supply trucks with electric drives (hybrid, fuel cell, or battery-powered) on heavily frequented stretches of highway via an overhead cable. Highways fitted with overhead electric wires can charge these electric trucks on the move.

Like railway locomotives, a connector on the top of the vehicle attaches to the overhead power lines that supply it with electricity used to drive the engine and charge the battery. The overhead cables deliver the positive and negative electrical circuit that’s picked up through a pantograph collector sitting on the roof.

Siemens Mobility is cooperating with Continental Engineering Services (CES) in the development and production of pantographs for trucks. Siemens Mobility specializes in railway electrification, while Continental Engineering Services is a development and production provider for automotive technologies. Siemens is providing the hardware for these tests, adapting equipment that’s been used for years to drive trains and urban street cars.

Siemens points out that overhead contact lines (OCL) can be installed with practically no impact on regular traffic operations. The vehicles using the system will be equipped with a battery for additional electric range outside of the OCL infrastructure, allowing for some gaps in the infrastructure while still enabling fully electrical operation. Thus,complex sections of the route, like motorway junctions, can be skipped. What’s more, OCL infrastructure can be phased in to meet growing energy demand by gradually adding more substations, more kilometers of infrastructure, or both.

The vehicle is free to leave the wires to overtake another vehicle or complete its journey away from the catenary using a separate on-board battery. The electricity transmitted along the active pantograph powers the truck’s electric motor and recharges an onboard electric battery, enabling it to travel to destinations outside of the electrified zones. At the push of a button, the pantograph can be connected to, and disconnected from, the electric battery.

Trucks are able to use the OCL flexibly because it requires no charging downtime. Instead, the technology is built for dynamic charging—driving and simultaneously charging their batteries without using onboard energy. This is possible due to the trucks’ ability to connect and disconnect from the OCL even at highway speeds.

High Efficiency and Unlimited Range

An eHighway solution enables unlimited operational range within the infrastructure. In Europe, 80% to 90% of long-haul trucking takes place on highways. Furthermore, this activity is highly concentrated: More than two-thirds of the fuel burned in long-haul trucking on German highways occurs on the busiest 4,000 km of the 13,000-km motorway network.

According to Siemens, hybrid trucks and battery electric vehicles (BEVs) that are connected to overhead contact lines have an efficiency of more than 80%. This offers advantages over alternative fuels that are produced synthetically, even using renewable electricity.

The system is currently being tested in an ongoing trial in Germany on three public test routes: the A5 in Hesse between the Zeppelinheim/Cargo City Süd junctions of Frankfurt Airport and Darmstadt/Weiterstadt; in Schleswig-Holstein on the A1 between the Reinfeld junction and the Lübeck motorway intersection; and the B462 federal road in Baden-Württemberg between Kuppenheim and Gaggenau.

So far, the sections of highway equipped with overhead cable in Germany are relatively short. Their purpose is to test how the system performs in everyday use. By the end of the year, more than 20 trucks will be using the systems in Germany.

Not every kilometer of motorway will have to be electrified in the future. The “National Platform for the Future of Mobility,” an initiative of the German Ministry of Transport, recommends equipping 4,000 km of motorway (nearly 2,500 miles) with overhead line technology by 2030, accommodating 60% of German truck traffic.

Collaborations and Cost

Who will bear the cost of the eHighway? The German government is expected to build the overhead cables, which cost an estimated 2.5 million Euros per km, or about $5 million per mile.

In Great Britain Siemens Mobility has just been brought on board a consortium that wants to build an eHighway test track on the M180 near Scunthorpe, an industrial town in North Lincolnshire, England. At least 19 miles of the M180 will be electrified, linking Immingham Port with the logistics hubs of Doncaster and its airport. This could be operational in 2024.

According to a report by the UK’s Centre for Sustainable Road Freight, a collaboration between Cambridge and Heriot-Watt Universities and organizations in the freight and logistics sectors, lower energy costs would allow the development money to be repaid to vehicle operators for new trucks in the first 18 months. The overall infrastructure would see investors paid off within 15 years. The report further said the electric road system would make it possible to tax the electricity used by trucks, enabling the government to replace revenues lost from taxing diesel fuel.

The eHighway has some practical technical hurdles to overcome. Overhead lines may be adversely affected by strong winds causing wires to swing. Storms can knock the power out with lightning strikes on the overhead wires, stopping trucks following a power surge. During cold or frosty weather, ice may coat overhead lines, not only causing poor electrical contact between the collector and the overhead line, but also possibly resulting in electrical arcing and power surges.