Op Amps Shrug Off Automotive, Industrial, Other EMI

This article is part of the TechXchange: Delving into EMI, EMC and Noise

Along with temperature extremes, electromagnetic interference (EMI) is a pervasive issue in automotive, industrial, and even medical environments as it can stimulate noise-induced errors, disrupt circuit performance, and even induce gross malfunction. While there are techniques to attenuate EMI and mitigate its effects, these usually require addition of components such as shielding, ferrite beads, filtering, bypassing, and more, all of which raise cost and real-estate requirements as well as design and qualification uncertainty.

Recognizing this situation, ROHM introduced its EMARMOUR series in 2017, which provides superior noise immunity by combining a vertically integrated production system with proprietary analog design technology. Components in this series are designed to prevent malfunctions due to noise and do so without the need for special EMI-mitigation measures. The goal is to simplify up-front modeling and design, and reduce debug time and time to market.

The latest entries in this family are the BD8758xY series of rail-to-rail input/output high-speed CMOS op amps with enhanced EMI immunity. These op amps target applications requiring high-speed sensing in harsh environments, such as vehicle engine control units (ECUs) and anomaly detection systems for factory automation equipment. The single-channel BD87581YG-C and dual-channel BD87582YFVM-C devices in the series (both AEC-Q100 Qualified - Grade 1) are designed to prevent malfunctions due to noise without the need for special mitigation techniques.

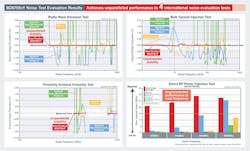

This claim is backed by quantitative tests including four international noise evaluation tests: ISO 11452-2 Radio Wave Emission Test, ISO 11452-4 Bulk Current Injection Test, ISO 11452-9 Proximity Antenna Immunity Test, and IEC 62132-4 Direct RF Power Injection Test (Fig. 1). For example, in ISO 11452-2 radio wave emission testing, the output voltage of the BD8758xY series fluctuates by less than ±10 mV, while standard products vary by more than ±300 mV in all frequency bands. This minimal disturbance can eliminate the need for EMI “countermeasures” at each frequency of concern, a step that can include up to 10 RC-filter components for a two-channel op amp.

The BD87581YG-C (SSOP-5 package) and BD87582YFVM-C (MSOP-8 package) op amps target automotive requirements such as sensor amplifiers, ECUs, electric power steering, and anti-lock braking systems due to their high slew rate and low input bias current. They also can be used for industrial applications. The specifications for the single- and two-channel devices are fairly similar (Fig. 2), but other modest differences in top- and second-tier specifications are called out in the datasheets.

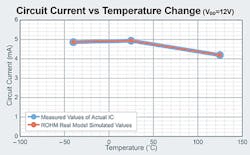

Today’s design begins with detailed simulation—usually Spice-based—and the fidelity of the model is obviously vital to assuring meaningful simulation results. ROHM’s new, high-accuracy simulation model (dubbed “ROHM Real Model”) uses model-based technology to faithfully reproduce the electrical and temperature characteristics of the actual IC, thus minimizing rework after prototyping. The models yield a very close match between the IC and simulation values for reliable verification and more efficient application development (Fig. 3).

In addition to the datasheet for the new pair, the four-minute video below discusses the attributes of these op amps, focusing on EMARMOUR EMI-resistant technology and ISO tests, as well as the Spice models.

The op amps are priced at under $1 in small quantities.