Driving the Future of HEV/EV with High-Voltage Solutions

Automotive manufacturers are building and increasing electrification in vehicle powertrains in the form of hybrid electric vehicles and electric vehicles (HEVs/EVs). HEV/EV sales are expected to represent between 5 and 20% of all cars sold by 20251.

The foundation for HEV/EV architectures is high voltage. These vehicles are based on high-voltage battery systems, such as +400 V for EVs and 48V for HEVs.

The basis for energy-efficiency improvements through high voltage will occur through the

advancement of switch-mode power supplies (SMPS) enabled by power electronics.

In addition to energy-efficiency improvements, the incorporation of high voltage makes system wiring less complex and lighter. This in effect lowers the vehicle’s overall weight, in addition to overcoming other disadvantages in a 12 V system2. High voltage also contributes to an overall vehicle efficiency improvement in terms of miles per gallon (MPG) for fuel-injection vehicles and miles per charge for HEVs and EVs.

The incorporation of advanced high-voltage devices such as wideband-gap semiconductors makes it possible for HEVs/EVs to withstand extreme high-temperature conditions and exhibit improved thermal-management efficiency.

This article will discuss the value of high voltage and SMPS in two subsystems—an on-board charger (OBC) and a traction inverter—with an emphasis on the advanced power electronics required to handle them and the overall trend toward wideband-gap semiconductors.

The SMPS Concept

SMPS is based on the operation of the on and off states of semiconductor power switches. SMPS implies no power loss at either state because there is zero current during the off state and zero voltage during the on state. In theory, this is 100% efficiency.

With pulse-width modulation (PWM), these switches operate under high switching frequencies, making the power-converter systems less bulky and smaller. There are three types of power conditioners found in powertrain electrification systems: AC/DC (rectifier), DC/DC (converter), and DC/AC (inverter).

SMPS in powertrain electrification

SMPS conditioners are realized in these power train sub-systems in HEVs/EVs:

- AC/DC

- Regenerative braking

- OBC

- DC/DC dual-battery system

- Battery management for lithium-ion (Li-Ion) batteries

- 48 V to 12 V bidirectional power supplies

- 400 V batteries (EVs only)

- Bidirectional 400 V to 12 V power supplies

- DC/AC

- Traction motors

- Auxiliary inverters

On-Board Charging

An OBC charges the batteries in an HEV/EV by connecting the vehicle to the grid, which is the electric power source. The grid is AC and the battery is DC, so the charger is an AC/DC system. Because the charger is built into the vehicle and therefore called “on-board,” it must be as small and light as possible.

One key trend currently under development is power (from the grid to charge the battery in the car) greater than 3.3 kW (which has been the traditional power level) to enable fast charging. Fast charging is vital in order for HEVs/EVs to compete against gasoline-powered vehicles, which drivers can fill up with gas in just a few minutes. However, with increasing switching frequency and adoption of wideband-gap power switches, the size and dimensions can be prevented from increasing proportionately larger.

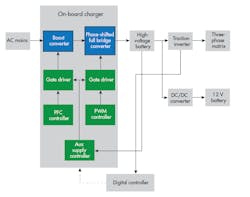

Figure 1 shows a block diagram of a powertrain electrification system, with a typical OBC subsystem highlighted in the gray box. It comprises two stages: an AC/DC stage with active power factor correction (PFC) and a DC/DC stage with a regulated voltage based on the battery specification to charge the battery3. Notice that there are several semiconductor integrated circuits (ICs) in green driving these stages. It is very important to select the optimal topology to reduce power losses in the power switches while developing these OBCs.

1. Shown is a block diagram of powertrain electrification.

A PWM controller (analog) IC that converts the AC voltage level to an intermediate DC bus voltage typically employs active PFC. One of the most common PFC topologies is the interleaved boost converter in the primary stage. The primary advantage of this topology that it delivers a lower ripple current on the DC/DC side as the converter switches out of phase and reduces conduction losses by paralleling the power switches. This topology also reduces the size of the inductors for electromagnetic interference (EMI) filtering.

One of the common topologies is a phase-shifted full-bridge converter for the secondary stage, which is a DC/DC converter. An inductor-inductor-capacitor (LLC) topology can deliver zero current switching to further improve efficiency, although the control aspect is a little more complex.

Since the key focus of an OBC is high power density (high power in a reduced space), the semiconductor choice is usually silicon power metal-oxide semiconductor field-effect transistors (MOSFETs) with 3.3 kW system power levels. The trend is moving towards modularizing these systems for scalability to 6.6 kW, 11 kW, etc. Automakers are also investigating high-voltage batteries beyond 400 V for fast chargers that can go as high as 20 kW. The problem, however, is heat dissipation. Therefore, in addition to reducing the overall size, managing the thermal issues is a key factor toward improving fuel efficiency. Using silicon power MOSFETs requires that you overcome its limitations.

Power levels beyond 6.6 kW that involve high temperatures require the addition of cooling systems such as large copper blocks with water jackets. This will affect vehicle size, weight and cost. Alternatively, wideband-gap semiconductors such as silicon carbide (SiC) have much higher operating temperatures (known as the junction temperature). Thermal conductivity is two to three times higher than silicon. The breakdown voltage is higher, and these semiconductors can switch at much higher frequencies with negligible power loss.

The higher operating temperature of SiC enables you to place the circuit close to the location where temperatures are high. Its high thermal conductivity eliminates the need for big copper blocks and water jackets. And achieving higher switching speeds in the 50 kHz to 100 kHz range enables a reduction in the overall power-circuitry size.

For both stages in an OBC subsystem (Fig. 1), a gate driver associated with each controller drives the power switches. Gate drivers convert PWM signals from the controller into gate pulses for the power switches to turn on or off. Because of the high voltage associated with the battery, there is galvanic isolation provided on the DC/DC side using a gate-drive transformer located between the gate driver and power switch. The level of isolation is usually reinforced, depending on the safety requirement levels.

However, one current trend employs an integrated isolated gate driver, which reduces board spacing, cost, and weight, at the same time providing high levels of noise immunity and robustness.

An auxiliary power supply is required for the gate drivers and to power the controllers at a regulated voltage. This is an offline power-supply IC that draws power from the high-voltage battery (400 V or above) to a regulated output depending on the controller and gate-driver supply requirement. The most common topology for such power supplies are flyback converters. The choice of power-supply IC is flexible and influenced by the power level, the number of outputs, and the accuracy of the regulation.

Traction Inverter

To convert electrical to mechanical energy in order to run the vehicle requires motors. DC motors were traditionally implemented for their simplicity and ease of control. However, AC motors traditionally exhibit higher efficiency compared to DC motors.

Tremendous progress has been made in building controllers for AC motors. Still, the power stored in the battery (HEV/EV) or gasoline must be converted from DC to AC in order to run AC motors. These inverters, called traction inverters, usually transfer power in the tens-of-kilowatts range (+50 kW).

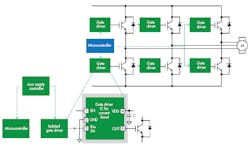

The power switches used in these full-bridge topologies are insulated gate bipolar transistors (IGBTs). Typical voltage levels for the power switches are 600V to 1200V. Considering the high power levels and voltage levels, a three-phase inverter uses six isolated gate drivers, as shown in Fig. 2. Each phase uses a high- and low-side IGBT switch, usually operating in the 5 kHz to 20 kHz range, to apply positive and negative high-voltage DC pulses to the motor windings in an alternating mode.

2. This depicts the three-phase traction inverter topology.

High-power IGBTs require isolated gate drivers to control their operations. A single isolated gate driver drives each IGBT. The isolation is galvanic between the high-voltage output of the gate driver and the low-voltage control inputs that come from the controller. In addition, these gate drivers need to have integrated protection features such as desaturation and short-circuit detection.

Isolated gate drivers can suffer from low drive strength, especially when the switches’ drive-current capability is below 2A. Drive applications traditionally use discrete n-channel-p-channel-n-channel (npn) p-channel-n-channel-p-channel (pnp) discrete circuits to boost the drive current. There are several gate-driver ICs on the market designed to replace discrete solutions.

Much like OBCs that can handle power levels beyond 6.6 kW, the trend in traction inverter subsystems is to use SiC power devices. Since the power levels in traction inverters are significantly higher compared to those in OBCs, the current solution is a SiC power module. SiC power modules can reduce parasitics such as ringing, improving switching speed, and increasing power density.

High-Voltage IC Solutions

Texas Instruments offers a variety of high-voltage IC solutions available in automotive grades, including:

- UCC28070-Q1 for active PFC control

- UCC28951-Q1 for phase-shifted full-bridge control

- UCC21520, UCC27524A1-Q1

- UCC27531-Q1 for gate-driver solutions

- UCC28700-Q1 and UCC28730-Q1 for auxiliary power-supply solutions

Summary

There are many benefits to the use of high-voltage and SMPS using power electronics in

powertrain electrification systems, particularly in OBC and traction inverter subsystems. There

are topologies common to the design of these systems. Semiconductor switches, controllers,

and gate drivers for these applications are moving toward wideband-gap semiconductors such as SiC because these devices can effectively handle high temperatures while lowering size and weight and improving powertrain efficiency.

References

1. Karl-Heinz Steinmetz, Texas Instruments, www.ti.com/lit/sszy026.

2. K. Morrow, D. Karner, and J. Francfort, “Plug-in hybrid electric vehicle charging infrastructure review,” U.S. Dept. Energy–Veh. Technol. Program, Washington, DC, INL/EXT-08-15058, 2008B.

3. S. Singh, B.N. Singh, A. Chandra, K. Al-Haddad, A. Pandey, and D.P. Kothari, “A review of single-phase improved power quality AC–DC converters,” IEEE Trans. Ind. Electron., vol. 50, no. 5, pp. 962-981, Oct. 2003.