Power Driver Manages Automotive Front-Door Window, Mirrors, Tailgate, Lighting, and More

In just a few decades, we’ve come a very long way from those days of manually operated car windows, outside mirrors, and door locks. Now they’re all electrically powered with no manual linkage. Managing and delivering controlled power for the various motors and mechanisms used in the complicated door system and adjuncts—and it’s truly a system—is a substantial design challenge.

That’s where the STMicroelectronics L99DZ200G door-zone system IC offers a solution. This device enables a single-chip “front-drives-rear” arrangement for managing a front-door window, mirror, and lighting, as well as the rear-window lift. It does this with lower quiescent current, greater reliability, faster assembly, reduced bill of materials, and shorter development time than alternative solutions.

A Quick History Lesson

Some historical perspective may be useful here:1-3 Until about 50 years ago, all car windows were manually operated via a mechanical linkage actuated by a simple “hand-powered” rotary crank formally called the “window winder.” Each occupant of the car had to manage his or her own window using their arm as the power source (Fig. 1), and even the car driver could only do the adjacent window rather than all four.

Power windows were first introduced in the 1940s and initially used an electrically controlled, hydraulic-powered system; small electric-motor technology (size, power, and control) wasn’t advanced enough to allow motors to be embedded into the door. The mechanism that moves the window up and down is called the window regulator. Two basic types of window regulators are used: the cable type and the gear-drive type.

In the 1960s, though, the Cadillac Fleetwood came standard with windows powered solely by electric motors and, within about a decade, power windows were a standard feature on most cars—a fairly quick rate of mass-market adoption.

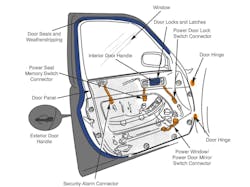

By the turn of the century, the car door was transformed into a complex electromechanical subsystem with all functions activated electronically and implemented electrically (Fig. 2), without an all-mechanical backup system. (There was an intermediate period when doors and windows had both electrical and mechanical control, to overcome customer hesitation and provide a comfort factor.) Today’s car-door subsystems are so advanced that they even have application-specific voltage monitors.4

The Door-Zone IC

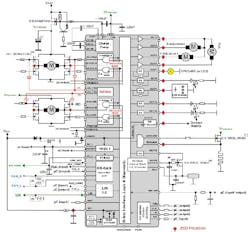

The L99DZ200G incorporates two configurable half-bridges (7.5 A), two other half bridges (0.5 A), a gate driver for an external MOSFET to control mirror heating, a control block and high-side driver for electro-chromic mirror dimming, and five LED high-side drivers (Fig. 3).

Three of the high-side drivers can operate in constant-current mode to power lighting modules that have high input capacitance; the other two high-side drivers are suitable for controlling ordinary LEDs. The L99DZ200G also provides power management, with two 5-V low-dropout regulators for the host microcontroller and peripherals. Connections for control and communication include a LIN 2.2a transceiver, high-speed CAN transceiver, and SPI 4.0 interface.

With its two bridge drivers, the L99DZ200G is able to control two spindle motors simultaneously and handle a third so-called “cinch motor” to close a powered tailgate or trunk. This three-motor control can be used to automatically open and close the power trunk of the car.

To accomplish that, the two spindle motors run in parallel and in the same direction to move the trunk door up and down, while the cinch motor is activated once the movement of the trunk is completed to lock/unlock the trunk door. Both drivers allow for operation in generator mode, which activates both low-side MOSFETs simultaneously to protect the device if an overvoltage is detected in the supply rail.

That last point is related to a subtlety that highlights the reality of going from design to a real production line. Carmakers traditionally must protect their powered trunk drivers from manual handling at the end of the manufacturing process: When machines or workers manually lift the trunk, it automatically spins the motors and turns them into a generator that creates a voltage spike on the IC driver’s pin, which can then destroy that component.

Protection Features

To solve this problem, designers add appropriate protection components. The L99DZ200G offers a new solution in the form of the generator mode, which turns on the device’s low-side external MOSFETs when the motors start to act as a generator. When that happens, the device locks the motors to prevent a voltage spike. Hence, designers no longer have to add external components to deal with this particular situation.

Diagnostic and protection features include temperature monitoring and thermal protection, a dedicated failsafe block to pull down the gates of the external high-side MOSFETs, and open-load and overcurrent detection for all outputs. A current-monitor output pin is provided for each high-side channel. Overcurrent recovery and thermal expiration allow operation to resume automatically after a fault.

There are also reverse-battery protection and system-safety features, including a configurable window watchdog and programmable reset generator. The device meets automotive standards as it tolerates 25 kV on its LIN pin and 15 kV on its CAN pin, eliminating the need for external protection components.

Eval Board

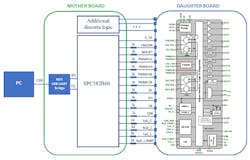

Designers contemplating using a high-functionality component such as this one would greatly benefit from a convenient way to set up and exercise it. For this reason, ST offers the EVAL-L99DZ200 evaluation board (Fig. 4), with documentation including schematic, board-layer drawings, and bill of materials.

The system rests on a motherboard (150 × 120 mm) with an SPC582B60 microcontroller, while the L99DZ200G resides on a 36.8- × 35.6-mm daughterboard (Fig. 5). The platform includes battery-reverse protection and two full-bridges made out of four power MOSFETs. The STSW-L99DZ200 graphical user interface enables the user to set the L99DZ200G control parameters and simultaneously display real-time diagnostics information as current output and battery voltage monitoring.

The AEC-Q100-qualified L99DZ200G is in production now, packaged as a 10- × 10-mm LQFP64 device. Pricing starts from $4.20 for orders of 1000 pieces. The L99DZ200G home page includes links to the 198-page datasheet (yes, it’s 198 pages), various application notes including a comprehensive 22-page Technical Note TN1354 “L99DZ200G driving three motors with two H-bridges: configuration and use cases,” and more. There’s also an insightful blog post “L99DZ200G: How One Front Door Driver Can Also Power a Rear Window, a Power Trunk, and More.”

References

1. GoMechanic, “Power Windows In Cars and the Interesting History Behind Them”

2. Wikipedia, “Power Window”

3. Samarins, “Power window regulator, window motor: problems, testing, replacement”

4. Maxim Integrated/Analog Devices, “MAX16137 – 1% Accuracy Single-Window Voltage Monitor with BIST”

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.