Inductive Position Sensor Targets EV Motor-Control Applications

Check out the other 2023 IDEA Award Nominees.

There’s a large gap between the theoretical concept of sensing a tangible real-world physical variable, and what it takes to do so in the harsh reality of the application. That’s why there are so many sensor approaches and associated electronics for measuring basic parameters such as distance, temperature, speed, pressure, mass, and more.

For example, sensing important factors that involve motor drive and position in the automotive environment is a multifaceted mechanical, environmental, and electronics challenge. Addressing this situation, the LX34070 IC from Microchip Technology targets electric-vehicle (EV) motor-control applications.

This high-speed inductive-position sensor includes differential outputs, fast sample rates, and features that make it functional-safety-ready for ISO 26262 compliance in the Automotive Safety Integrity Level-C (ASIL-C) classification and AEC-Q100 certification to Grade 0.

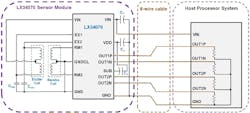

Inductive sensing isn’t new, of course, and uses an ac-excited primary coil—here, fabricated as part of the PCB—to generate a magnetic field that couples to two secondary coils (also part of the board). A small metal target object disturbs this magnetic field, resulting in each secondary coil receiving a different voltage; the ratio between the voltages is used to calculate absolute position (Fig. 1).

By using board traces rather than transformer-based magnetic windings and coil structures, the LX34070 has negligible size and mass compared to alternative approaches. Accuracy is improved since the performance doesn’t depend on absolute magnet strength, instead it’s differential. The device further improves robustness by actively rejecting stray magnetic fields—a major concerns in EVs.

These and other features give designers enhanced flexibility in terms of where they can place the thin, lightweight PCB-based LX34070 solution in their EV motor-control designs. The two output signals that represent the absolute position may be used in single-ended configuration for reduced pin count or as differential signals to maximize noise immunity where needed.

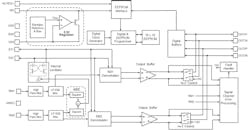

As expected, the IC is internally complex (Fig. 2).

It includes an exciter circuit for driving the primary coil and two independent analog channels with input filtering and amplitude demodulation for the secondary side. In addition, differential/single-ended output buffers with accurate common-mode level and automatic gain control (AGC) maximize signal resolution over large air-gap ranges.

Of course, as faults are always a concern, there’s circuitry for protection against output short circuits, detection of loss of power supply and ground, and detection of faults at the exciter-coil pins and receive-coil pins.

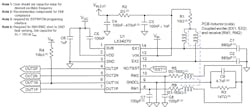

The 36-page datasheet explains the theory of operation, includes operating information, provides details on setting parameters in its EEPROM, as well as an application circuit with suggested component values (Fig. 3).

Microchip also offers links to a wide range of Inductive Position Sensor Design Resources, including evaluation kits and software-based tools, their perspective on “Advantages of Inductive Position Sensors vs. Hall Effect Sensors” (Hall-effect sensor vendors will undoubtedly have some different views here), and a nine-minute tutorial video “Inductive Position Sensing Concept Demo.”

The LX34070 operates from a 4.5- to 5.5-V supply with protection up to 18 V; it's housed in a 14-pin TSSOP package and is rated for –40 to +150°C operation.

Check out more articles/videos as part of our Sensors Converge coverage.