Touch-Panel Controller IC Also “Plays Well” with Rotary Mechanical Knob

Touchscreens and touchpads haven’t totally taken over the human-machine interface (HMI) function and many situations still exist where discrete switches or even the classic QWERTY keyboard remain the best choice. But there’s no doubt that touch-driven display interfaces are certainly the preferred or only viable option in many cases. They offer flexibility, dynamic reconfigurability, user convenience and safety, and many other virtues compared to a standard keyboard or even dedicated, hardwired switches and knobs.

However, there are also many applications where the user of a touch-based interface needs an old-fashioned rotary knob as well, to provide intuitive, natural input action for a key parameter such as temperature or audio volume.

Addressing this mixed input-mode requirement, Microchip Technology introduced the maXTouch Knob-on-Display (KoD) family of touchscreen controller ICs for screens up to 19 inches. The company maintains it’s the first automotive-grade touchscreen controller family with native support for the detection of, and reporting on, capacitive-based rotary encoders. Thus, you get both the appearance and flexibility of a touch display combined with the convenience, comfort, and directness of a control knob.

What is Knob-on-Display Tech?

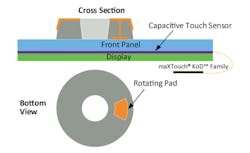

Unlike the constraints when using traditional mechanical-rotary encoders, this new technology supports mounting the knob directly onto the display without an opening in the panel or any customization of the touch pattern. This increases design flexibility and potential reliability, which helps save system cost. It’s not just for automotive applications, either, as it also enables design of a sealed human-machine interface (HMI) module, which is increasingly popular for in-home appliance and industrial applications.

There are other advantages as well. The KoD technology eliminates the need for custom touch-sensor patterns. Thus, designers can easily implement a different knob count, shape, and position serving a variety of similar but differentiated end-user products. These customized configurations are adjustable without changing the embedded firmware of the maXTouch KoD touch controller, leading to a faster and more flexible development cycle.

With the maXTouch KoD controllers, designers can keep the comfort of a rotary-type encoder-input device but combine it with a modern and innovative design using smart surfaces and multi-touch displays.

Among its other features, this family of controller ICs with SPI and I2C interfaces reduce the number of active components needed to create a modern HMI design (Fig. 1).

The ICs also eliminate the need for an opening in the front panel or display, which reduces costs and extends product lifetime by preventing moisture and dust from entering the system (Fig. 2).

The knob itself is a passive mechanical element, and specifically designed to include at least one conductive pad (Fig. 3). The maXTouch KoD touchscreen controller senses the pad capacitively through the touch sensor. Its patented algorithms ensure the correct sensing and calibration of the knob’s location while maintaining multi-touch operation over the rest of the touchscreen. As it doesn’t require a specific touch-sensor pattern under the knobs, it can be used with a standard touch display.

The four ICs in the family support different touch-channel densities and approaches to implementing the rotary knob (see table below).

Customization

The KD variant enables them to choose their knob design partner and create their own solution using a reference design jointly developed with BNL Bearings—offering the option to fully customize the design for specific applications. The additional MK variant supports the Magic Knob developed by Panasonic Industry Co. Ltd.

While keeping the flexibility to be mounted on standard touch sensor patterns, the Microchip Panasonic Magic Knob (MPMK) solution provides a high level of customization for rotation and push haptic feedback, as well as for the top-cover material selection.

There’s a three-minute video showing some of the many ways these 3.3-V controller ICs can be a part of an HMI design. The individual IC datasheets (85 pages each, and with a very helpful index) linked via the product page are a good starting point for design-in efforts, but products such as these ICs obviously require more than just that document. Microchip provides a suite of both hardware and software development tools to shorten the development cycle with a capacitive rotary knob.

On the hardware side, there’s the ATEVK-MXT2912TDAT-A: 15.6” and ATEVK-MXT2113TDAT-A: 13.3” OGS touch-panel kit including development board with USB bridge, and a capacitive rotary-encoder knob reference design with 30 detents and push functionality. For software, there’s the maXTouch Studio integrated development tool with dedicated family plugins for knob design and parameter settings.