Interest in harvesting and converting energy for smart cars is on the rise. Several factors are driving this interest. These include the steep costs and lifetimes of batteries for electric and hybrid electric vehicles, progress in making energy harvesting techniques more favorable for the auto market, and government regulations regarding fuel efficiency and exhaust emissions. Also acting as an impetus is much academic research that promises to lay the foundation for practical auto energy-harvesting platforms. Some auto companies like Volvo, GM, and Audi are working with other partners to bring to market actual products.

One important regulation is the government’s CAFE (Corporate Average Fuel Economy) standard. It was enacted in 1975 to improve the average fuel economy of cars and light trucks (trucks, vans, and sport utility vehicles).

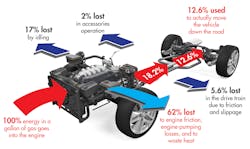

This diagram illustrates the paths of energy through a typical gas-powered vehicle in city driving. (Source: U.S. DoE data and gas-miser.com/?page_id=93)

Lei Zuo, professor of mechanical engineering at Virginia Tech University, has developed an energy-harvesting shock absorber that translates the vertical vibrations of a car’s suspension system into rotational motion, which then drives a generator that delivers electricity to charge a car’s battery and to power other devices. The shock absorber has a unique combination of gears that allow motion in both directions (up and down) to harvest electrical energy.

There are some energy-harvesting products on the market that might be suitable for automotive applications. One of is these is an energy-harvesting module from Jennova Inc. that can generate electrical power in the 10-mW range using its patented electrodynamic energy-harvesting vibrational technology. Jennova, a manufacturer of energy-harvesting devices for low-power demands in IoT and other connected devices, demonstrated its product at last year’s Sensors Expo connected to an Analog Devices' ADP5090 boost-battery management chip (with small batteries and a supercapacitor attached) and powering an Anaren A20737-MSDB1 Bluetooth multi-sensor development board (below).

Jennova’s energy-harvesting module is connected to an Analog Devices ADP5090 boost-battery management chip (with small batteries and a supercapacitor attached) and powering an Anaren A20737-MSDB1 Bluetooth multi-sensor development board. (Source: Jennova Inc.)

“There’s been an increase in energy-harvesting technologies that generate electrical energy from unlimited, excitable, and external sources, while remaining robust and durable in a relatively small form,” says Christian Pennisi, founder and CEO of Jennova. “That means more opportunities are available for smart cars.”

A kinetic energy recovery system (KERS) is used by Sweden’s auto maker Volvo, which is working with the Swedish government and the UK’s Flybrid Automotive, part of the Tototrak Group. They’re using Flybrid’s GKN Gyrodrive hybrid technology for energy generation from a flywheel’s motion. The first full-scale trial of a rear-axle mounted flywheel in a front-wheel drive car using Tototrak’s continuously variable transmission (CVT) has shown promising results in fuel savings.

Researchers at Germany’s University of Bremen have demonstrated that kinetic energy obtained from acceleration sensors mounted in a car’s engine compartment can be converted to electricity, resulting in a self-powered wireless communication system.

To demonstrate the potential use of kinetic to electrical energy from a car’s engine vibrations, four acceleration sensors were placed—one on the cooling tank, one on the windshield washer tank, one on the cover of the oil filter neck, and one near the air filter. Collected data showed a strong correlation between engine speed, load, and sensor acceleration data. The researchers point out, however, that their findings can only be used as a basis for developing an optimally tuned system, depending on the best sensor placements used.

Italy’s Magneti Morrelli, a subsidiary of Fiat, is working on an updated version of an energy recovery system that combines the kinetic energy during braking with the recovery of energy from hot exhaust gases. The new system is connected to an electric motor-generator, which is in turn connected to a car’s drive shaft. Results from an earlier version showed that the system can reach up to 40,000 revolutions/minute.

About the Author

Roger Allan

Roger Allan is an electronics journalism veteran, and served as Electronic Design's Executive Editor for 15 of those years. He has covered just about every technology beat from semiconductors, components, packaging and power devices, to communications, test and measurement, automotive electronics, robotics, medical electronics, military electronics, robotics, and industrial electronics. His specialties include MEMS and nanoelectronics technologies. He is a contributor to the McGraw Hill Annual Encyclopedia of Science and Technology. He is also a Life Senior Member of the IEEE and holds a BSEE from New York University's School of Engineering and Science. Roger has worked for major electronics magazines besides Electronic Design, including the IEEE Spectrum, Electronics, EDN, Electronic Products, and the British New Scientist. He also has working experience in the electronics industry as a design engineer in filters, power supplies and control systems.

After his retirement from Electronic Design Magazine, He has been extensively contributing articles for Penton’s Electronic Design, Power Electronics Technology, Energy Efficiency and Technology (EE&T) and Microwaves RF Magazine, covering all of the aforementioned electronics segments as well as energy efficiency, harvesting and related technologies. He has also contributed articles to other electronics technology magazines worldwide.

He is a “jack of all trades and a master in leading-edge technologies” like MEMS, nanolectronics, autonomous vehicles, artificial intelligence, military electronics, biometrics, implantable medical devices, and energy harvesting and related technologies.