Manufacturers of next-generation electric vehicles (EVs) and hybrid electric vehicles (HEVs) are eyeing the use of wide bandgap (WBG) silicon-carbide (SiC) and gallium-nitride (GaN) devices. These two technologies help create devices with higher power handling, greater efficiency, higher frequency operation, faster switching times, smaller size, and fewer thermal-management challenges than conventional silicon power transistors, diodes, and MOSFETs.

Relatively low-cost high-electron mobility transistors (HEMTs), insulated-gate bipolar transistors (IGBTs), and venerable silicon MOSFETs continue to be used widely to power automotive applications. But silicon-based technologies are reaching their performance limits, even though IGBTs and super-junction MOSFETs that employ vertical instead of planar transistor gates have already made possible higher switching speeds and lower losses.

In the IGBT arena, modular IGBTs like STMicroelectronics’ ACEPACK (Adaptable Compact Easier Package) 1 and 2 series using field-stop trench technology deliver the best combination of low on-resistance and high switching performance in the 3- to 30-kW range for EVs and other applications.

Two configurations are available, giving a choice of six-pack modules that contain six IGBTs with freewheel diodes as a three-phase inverter; or a as a power integrated module (PIM) that provides for a complete driver power stage. The PIMs are converter-inverter-brake (CIB) devices that integrate a three-phase inverter, and a braking chopper for handling energy returned from the load. Various PIM/CIB and six-pack devices are available in voltages of 650 V or 1.2 kV for currents of 15 A to 75 A. (Fig. 1).

1. The ACEPACK1 (left) and 2 (right) IGBT power modules developed by STMicroelectronics deliver advanced and economic performance for EVs and other applications. (Courtesy of STMicroelectronics)

GaN and SiC Looming

GaN and SiC power devices are now becoming more attractive as potentially more economical approaches to power EVs and HEVs. While they cost much more than silicon-based power ICs, improvements in their manufacture are being made to reduce the price difference. Proponents of these WBG technologies, however, argue that a net savings is possible when you consider the total savings that GaN and SiC can offer car makers, factoring in lighter weight, smaller size, and higher fuel and other efficiencies.

By enabling greater power integration than silicon ICs, GaN devices can improve the efficiency and reduce the cost of electrical converters. This will accelerate their adoption in applications such as EV charging stations, servers, automobiles, and industrial systems.

On the GaN Front

Successful processing of GaN devices done by France’s Exagan was achieved through a joint effort with the X-FAB foundry to develop GaN transistors on 200-mm wafers. Exagan and X-FAB successfully resolved many of the challenges related to material stress, defectivity, and process integration while using standard fabrication equipment and process recipes. Combined with the use of 200-mm wafers, this is said to significantly lower the cost of mass-producing GaN-on-silicon devices.

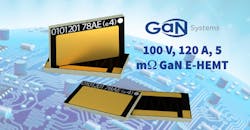

Progress in GaN technology can be seen in GaN Systems’ enhancement-mode (e-HEMT) device with a record-setting 100-V/120-A, 5-mΩ power transistor for the growing 48-V automotive market. The e-HEMT GS-010-120-1-T power transistor leverages all of the die design and packaging advantages delivered from GaN Systems. Another GaN product is the GS-065-120-1-D supplied in die form. It’s claimed to have the lowest RDS(on) of 12 mΩ and the highest 650-V rating in a GaN HEMT in the industry (Fig. 2).

2. GaN Systems’ 100-V/120-A, 5-mΩ e-HEMT power transistor is aimed at the growing 48-V automotive market. (Courtesy of GaN Systems)

Efficient Power Conversion (EPC) recently showed off its enhancement-mode EPC2050, a 350-V, 65-mΩ, 26-A power transistor that’s 20X smaller than comparable silicon devices. It’s intended for EV charging, solar power inverters, motor drives, and multilevel converter configurations.

On the SiC Front

Wolfspeed, a Cree company and a leader in SiC technology, last year showed the first all-SiC, 1.2-kV, 300-A power-module reliability benchmark that passes harsh environment qualification tests for simultaneous high humidity (85%) and high temperature (85º) at a 960-V rating.

“This device is yet another industry first driven by Wolfspeed,” says John Palmour the company’s CTO and co-founder, “to meet anticipated system requirements for 2020 and beyond. The value of reducing size, weight, waste heat, and improving overall efficiency are multiplied in EVs, and SiC chips are being integrated in to both on-board an off-board charging systems.”

Wolfspeed has already demonstrated that SiC devices could reduce drivetrain conversion losses by up to 78%, resulting in a 5% to 10% improvement in battery efficiency overall.

Wolfspeed also offers the C3M SiC n-channel enhancement-mode MOSFET in die form capable of blocking 1 kV across its entire operating-temperature range to reduce de-rating requirements. IT can be configured in parallel for higher current capability or in series for higher voltage blocking capability. And unlike SiC MOSFETs, it has a fast intrinsic diode with low reverse recovery, eliminating the need for external anti-parallel diodes.

3. This 1.2-kV 400-A full SiC power module from Rohm reduces switching losses by 64% at a chip temperature of 150ºC. Loss calculations conducted with a pulse-width-modulated (PWM) inverter drive resulted in a 30% reduction at 5 kHz and an even more substantial reduction in total loss of 55% at 20 kHz. (Courtesy of Rohm)

Rohm offers a 1.2-kV, 400-A full SiC power module that reduces switching losses by 64% at a chip temperature of 150ºC. Loss calculations conducted with a pulse-width-modulated (PWM) inverter drive resulted in a 30% reduction at 5 kHz, and an even more substantial reduction in total loss of 55% at 20 kHz, the firm reports (Fig. 3).

Microsemi just introduced SiC MOSFETs and Schottky Barrier diodes targeted at industrial and automotive markets. The 1.2-kV, 40-mΩ SiC MOSFETs are avalanche-rated and feature short-circuit protection for automotive power applications (Fig. 4).

4. A series of 1.2-kV 40-mΩ SiC MOSFETs and Schottky barrier diodes from Microsemi are targeted at industrial and automotive markets. They’re avalanche-rated and feature short-circuit protection for automotive power applications.

Wolfspeed introduced a 900-V, 10-mΩ MOSFET rated for 196 A of continuous drain current at a case temperature of 25˚C. This device reduces EV drivetrain inverter losses by 78% based on EPA combined city/highway mileage standards. This efficiency improvement offers designers new options in terms of range, battery usage, and vehicle design.

Greater Investments and Larger Markets

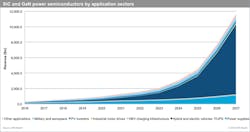

The adoption of SiC and GaN power semiconductors in the main powertrain inverter HEVs will lead to revenue rising at a compound annual growth rate of over 35% after 2017, reaching $10 billion in 2027, forecasts Richard Eden, an analyst at IHS Markit Research. He foresees the overall market for such power devices to reach $1 billion by 2020, energized by EVs, power supplies, and photovoltaic inverters.

The IHS forecast foresees power GaN-on-silicon wafers to achieve price parity with silicon-based MOSFETs and IGBTs while providing the same superior performance. And that will occur by 2027. Revenue is expected to climb to $600 million by 2024, and over $1.76 billion by 2027 (Fig. 5).

5. Various applications will drive SiC and GaN power semiconductors by applications. (Courtesy of IHS Markit)

We need only look at what major car makers are planning for their future EVs and HEVs and gauge their interest in WBG power devices. Cree announced that Shinry Technologies, based in Shenzhen, China, and focused on energy-efficient applications in transportation and lighting, employed Cree’s 1.2-kV family of SiC MOSFETs in its new, high-efficiency EV power converters to achieve 96% efficiency. The company said that Cree’s C2M SiC MOSFETS also enabled a 25% reduction in product size and reduced peak power losses by over 60% compared to the traditional silicon versions.

“Our customers care a great deal about efficiency, compact size, and system weight and cost,” says Dr. Wu Ren Hua, CEO of Shinry Technologies. The Cree SiC products are used in Shinry’s latest 3- to 1- kW dc-dc converters designed for use in electric buses.

Recently, Wolfspeed supplied Ford Motor Company—in collaboration with the U.S. Department of Energy (DoE)—with a full-SiC, 400-A power module designed around a 900-V, 10-mΩ chip. The module contains four MOSFETs connected in parallel to achieve a drain resistance RDS(on) of 2.5 mΩ. Wolfspeed engineers have since demonstrated the capability to use these chips to create an 800-A, 1.25-mΩ module.

BMW’s investment arm BMW i Ventures recognizes the importance of GaN technology for future EVs, HEVs, and all-electric autonomous cars, as evidenced by its relationship with GaN Systems Co.

“GaN Systems’ power transistors have created new opportunities for engineers to build the power electronics demanded by today’s systems and is the next stepping stone in miniaturization,” says Uwe Higgin managing director of BMI I Ventures. “There are many examples of how GaN benefits power systems, and increasing the efficiency of power conversion will account for billions of dollars in cost savings.”

In commenting on BMW I Ventures’ last year’s investments, Jim Witham CEO of GaN Systems added that “our customers have validated the GaN value proposition of small, efficient, low-cost electronics.”