Automakers are finding that testing their products in virtual scenarios allows them to increase the safety of their products, as well as decrease their time-to-market. From headlights to autonomous vehicles, the best way to design and test within the automotive industry is through high-tech simulation and virtual-reality software.

In the auto industry last year, only two out of 37 mid-sized SUV models passed the Insurance Institute for Highway Safety (IIHS) headlights test. When headlights are the most basic form of night crash prevention, this high failure rate brings to light a critical need for improvement.

Although headlight technology has developed quickly over the last few years, U.S. government regulations on headlights have not guaranteed consistency when it comes to the amount of illumination provided in actual use. While your headlights may satisfy Federal Motor Vehicle Safety Standards (FMVSS) regulations, these regulations should be considered the minimum requirement when there’s so much improvement to be made.

LED and high-intensity discharged (HID) lamps have started replacing traditional halogen lamps, and many automakers offer curve-adaptive headlights. Nonetheless, car models on the market today are still failing safety tests.

Auto manufacturers that work to improve headlight performance have the opportunity for a distinct competitive advantage, as they’re making strides toward ensuring the safety provided by headlights. Whether headlights are paired with reflectors or projector lenses, the results should illuminate the road ahead adequately, without temporarily blinding oncoming drivers. The increased safety would add value to the vehicle, in addition to meeting the need to increase auto safety and reduce the number of fatal car accidents.

High-Tech Test

To meet this goal, automakers have turned their sights toward high-tech testing methods, including virtual reality and simulation software, that allow the comparison of headlights precisely against IIHS standards. Automotive OEM companies and tier-1 suppliers usually are restricted to only being able to test their headlights after the vehicle has been produced.

However, with simulation technology, they can predict a poor IIHS rating during the early development of their headlights, and make real-time adjustments to their models. Using simulation and VR tech can also help companies push the limits of the visible distance and width of their headlight beams while maintaining regulatory compliance.

(Source: ANSYS)

As simulation technology becomes even more hyper-realistic, testing models this way also eliminates the need for real-world night testing of already-produced headlights. Real-world tests are costly not only in terms of needing a physical product to test, but in terms of the cost of necessary personnel and space to conduct said tests, too. The alternative of virtually testing prototypes instead reduces the associated safety risks of testing on real-world tracks and public roads.

Testing the Autonomous

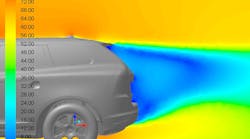

In addition to the practical application of testing headlights, virtual reality and simulation software is being used to test the future of transportation: autonomous vehicles. Simulation technology can be applied to virtually recreate the cameras and sensors used by autonomous vehicles, and allow for virtual testing that ensures the safety of all participants. Using this tech, automakers can test autonomous vehicle prototypes on virtual test tracks, recreating realistic traffic conditions, including weather, oncoming cars, and pedestrians.

Manufacturers of self-driving vehicles have the ability to make adjustments to their designs without creating an entirely new product. Being able to do so means that these cars can be tested and validated much quicker, decreasing time-to-market and allowing consumers to experience them sooner than expected. The decrease in time-to-market is one of the most exciting developments, as physical prototypes that once took a few weeks or months can now be created virtually in a single day.

VR and simulation tech also allows automakers to test other aspects of vehicle technology. New applications integrating digital-micromirror (DMD) technologies are emerging for both intelligent pixel headlights and head-up display (HUD) systems. VR and simulation providers that host a library of digital light processing (DLP) dedicated to HUD in automotive make the process of testing even simpler.

A Sound Idea

A new dimension to the testing of future vehicles, to get a multisensory experience, is to incorporate sound simulation into the virtual prototype. Examples include the sounds of an engine or a car door closing. Sound simulation not only contributes to the pleasure of driving, but it also provides valuable information on the quality and safety of the car. Furthermore, it’s possible to evaluate and validate many sound effects through simulation, from the sound quality in the cabin and the noise of a shock absorber, to the HMI sound design and the sound of a radio.

A use case for testing sound in virtual reality would be the trend of new electric vehicles (EVs). EVs can be confusing to many drivers due to their silent and smooth operation, as drivers and pedestrians are used to the noise of vehicle engines.

Acoustic simulation in virtual reality allows OEMs to assess the external sound system developed to simulate engine noise and warn people that the car is coming, ensuring that safety requirements are met. The sound systems associated with a car's speed or engine RPM can be validated to provide realistic feedback to the driver, enhancing the overall driving experience. Finally, various sound landscapes can be fine-tuned to offer a customized and holistic virtual driving experience.

Overall, virtual reality and simulation software enable car manufacturers to ensure their products meet the most stringent of safety requirements, as well as test their products in an environment that poses no threat to the testers or the real world. With this technology, auto companies can cost-effectively develop headlights that will provide the ability to avoid fatal collisions and develop autonomous vehicles that can accurately detect and avoid road obstacles. Time-to-market is accelerated as well, making it possible for automakers to bring their products to consumers faster without sacrificing quality.

Jacques Delacour is the Optics and VR Business Line Director of ANSYS.