In developed regions such as Europe and North America, integration of Internet of Things (IoT) technology in vehicles is expected to boost the adoption rate of vehicle-tracking systems. Such systems can be active or passive—they collect data in the same way and are equally accurate.

The main difference between active and passive involves time. Active trackers are also called real-time trackers, because they transmit data via satellite or a cellular network, which instantly indicates where the vehicle is located. In this way, a computer screen can display this movement in real-time. As such, active tracking the best choice for businesses interested in improving the efficiency of their deliveries and monitoring their employees driving in the field.

An active tracker also has geo-fence capabilities (think of this feature like a force field), providing an alert when the vehicle enters or exits a predetermined location (source: RMT Corporation). These kinds of systems can also help prevent theft and help recover stolen vehicles. Of course, active GPS tracking devices are more expensive than passive ones and require a monthly service fee.

Passive trackers, on the other hand, are less costly, smaller, and easier to conceal. Their downside is limited data storage. They store the information on the device instead of transmitting the data to a remote location. The tracker must be removed from the vehicle and plugged into a computer to view any of its information.

Passive systems are good for people tracking their mileage for work purposes, or for businesses interested in reducing the misuse of their vehicles. Also, they’re often chosen for monitoring the actions of people as well (think of detective work). Passive trackers are a good choice if immediate feedback isn’t required and there’s a plan to regularly check the device’s data.

Both types of trackers are portable in nature and have a relatively small form factor. Therefore, battery power is required, as is backup capability to preserve data in case of power loss. Due to the higher automotive system voltages and currents required to charge the battery (typically a single-cell Li-ion), a switch-mode charger is desirable for its higher charging efficiency when compared to a linear battery charging IC, since it generates less heat in the form of power dissipation.

In general, embedded automotive applications have input voltages up to 30 V, with some even higher. In these GPS tracking systems, a charger with the typical 12 V to single-cell Li-ion battery (3.7 V typical) with added protection to much higher input voltages (in case of voltage transients from battery excursions), plus some sort of backup capability, would be ideal.

Design Issues for Battery-Charging ICs

Traditional linear-topology battery chargers are often valued for their compact footprints, simplicity, and modest cost. However, drawbacks associated with these chargers have included limited input and battery voltage ranges, higher relative current consumption, excessive power dissipation (heat generation), limited charge termination algorithms, and lower relative efficiency.

On the other hand, switch-mode battery chargers are popular choices due to their topology; flexibility; multichemistry charging; high charging efficiencies that minimize heat to enable fast charge times; and wide operating voltage ranges. Of course, tradeoffs always exist. Some downsides of switching chargers include relatively high cost, more complicated inductor-based designs, potential noise generation, and larger footprint solutions. Modern lead-acid, wireless-power, energy-harvesting, solar-charging, remote-sensor, and embedded automotive applications are predominantly powered by switch-mode chargers for the positive reasons stated previously.

Traditionally, a tracker’s backup power-management system for batteries consisted of multiple ICs, a high-voltage buck regulator, and a battery charger, plus all of the discrete components—not exactly a compact solution. Hence, early tracking systems weren’t very compact in form factor. A typical application for a tracking system uses an automotive battery and a single-cell Li-ion battery for storage and backup.

Why is it, then, that tracking systems require a more highly integrated power-management solution? Primarily, it’s needed to reduce the size of the tracker itself; smaller is better in this market. Furthermore, there are requirements for safely charging the battery and protecting the IC against voltage transients; a need for system backup in case system power goes away or fails; and for powering the relatively lower rail voltages of the general packet radio service (GPRS) chipsets at ~4.45 V.

Power-Backup Manager

An integrated power-backup manager and charger solution, which solves the outlined objectives, requires the following attributes:

- Synchronous buck topology for high efficiency.

- Wide input voltage range to accommodate a variety of input power sources, plus protection against high-voltage

- Proper battery charge voltage to support the GPRS chipset.

- Simple and autonomous operation with onboard charge termination (no microcontroller needed).

- PowerPath control for seamless switchover between input power and backup power during a power fail event; it also needs to provide reverse blocking if a shorted input

- Battery-backup capability for system load power when the input is not present or

- Small and low-profile solution footprints due to space constraints.

- Advanced packaging for improved thermal performance and space

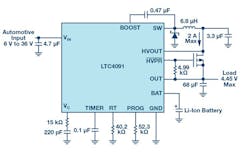

To address these specific needs, Analog Devices recently introduced the LTC4091—a complete, Li-ion battery-backup management system for 3.45- to 4.45-V supply rails that must be kept active during a long-duration main power failure.

The LTC4091 employs a 36-V monolithic buck converter with adaptive output control to provide power to the system load and enable high-efficiency battery charging from the buck output. When external power is available, the device can provide up to 2.5 A of total output current and up to 1.5 A of charge current for a single-cell, 4.1- or 4.2-V Li-ion battery.

If the primary input source fails and can no longer power the load, the LTC4091 provides up to 4 A to the system output load from the backup Li-ion battery via an internal diode, and relatively unlimited current if an external diode transistor is used. To protect sensitive downstream loads, the maximum output load voltage is 4.45 V.

The device’s PowerPath control provides a seamless switchover between input power and backup power during a power-fail event and enables reverse blocking with a shorted input. Typical applications for the LTC4091 include fleet and asset tracking, automotive GPS data loggers and telematics systems, security systems, communications, and industrial backup systems.

The LTC4091 includes 60-V absolute maximum input overvoltage protection, making the IC immune to high input-voltage transients. Its battery charger provides two pin-selectable charge voltages optimized for Li-ion battery-backup applications: the standard 4.2 V and a 4.1-V option that trades off battery run-time for increased charge/discharge cycle life. Other features include soft-start and frequency fold-back to control output current during startup and overload, as well as trickle charge, automatic recharge, low-battery precharge, charge timer termination, thermal regulation, and a thermistor pin for temperature-qualified charging.

1. Shown is a typical application for the LTC4091.

Housed in a low-profile (0.75 mm), 22-lead, 3- × 6-mm DFN package with a backside metal pad, the LTC4091 offers excellent thermal performance. The device operates from −40 to +125°C. Figure 1 shows a typical application schematic.

Thermal-Regulation Protection

To prevent thermal damage to the IC or surrounding components, an internal thermal feedback loop automatically decreases the programmed charge current if the die temperature rises to approximately 105°C. Thermal regulation protects the LTC4091 from excessive temperature due to high power operation or high ambient thermal conditions. It also allows the user to push the limits of the power-handling capability with a given circuit-board design without risk of damaging the LTC4091 or external components.

The benefit of the thermal-regulation loop is that charge current can be set according to actual conditions, rather than worst-case conditions with the assurance that the battery charger will automatically reduce the current in worst-case conditions.

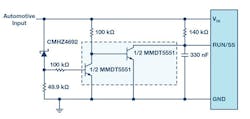

2. This cold-crank ride-through circuit automatically detects a brown-out condition.

Automotive applications experience large dips in supply voltage, such as during a cold-crank event. This can cause the high-voltage switching regulator to lose regulation, resulting in excessive VC voltage and consequently excessive output overshoot when VIN recovers. To prevent overshoot when recovering from a cold-crank event, it’s necessary to reset the LTC4091’s soft-start circuit via the RUN/SS pin. Figure 2 shows an example of a simple circuit that automatically detects a brown-out condition and resets the RUN/SS pin, re-engaging the soft-start feature and preventing damaging output overshoot.

Steve Knoth is Senior Product Marketing Engineer, Power Products, at Analog Devices Inc.