Ford had a research electric car way back in the early 1900s (Fig. 1). It was originally set to use Thomas Edison’s nickel-iron batteries, but they had a high internal resistance, so heavier lead-acid batteries were used at one point. Though the effort never developed into a product, a number of successful electric car vendors like Detroit Electric t did sell electric cars. The article, “How Henry Ford And Thomas Edison Killed The Electric Car,” by Daniel Strohl, provides some great historical context.

1. Fred Allison, who was an electrical engineer with Ford, sits atop the second Ford electric prototype.

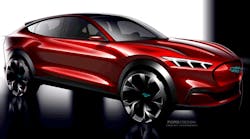

I was a bit disappointed when Ford announced it was discontinuing its conventional cars to focus on crossovers, SUVs, and trucks, since we own a Ford Fusion hybrid. Still, the company is continuing with its electric cars by adding a new Mustang Mach-E (Fig. 2) to the mix.

2. Ford’s Mustang Mach-E has a 300-mile range. The GT version has two motors that use 342 kW to generate 459 horsepower and 612 lb.-ft. of torque.

The Mustang Mach-E, featuring a 300-mile range, has a pair of motors for all-wheel drive. One handles the front wheels while the other drives the back wheels. The GT Performance Edition uses 342 kW to generate 459 horsepower and 612 lb.-ft. of torque. The vehicle goes from 0 to 60 in the mid-three-second range. Ford indicated it has a nationwide charging network that includes 12,500 public charging stations. One can tack on a 47-mile range with just 10 minutes on a 150-kW DC Fast Charger.

The interior (Fig. 3) includes a large, central display screen similar to that found in Tesla electric cars. The usual array of advanced driver-assistance system (ADAS) features come with the car as well, so it will likely be an interesting self-driving car platform in the future.

3. The futuristic Mustang Mach-E interior sports a large, central display screen.

The migration to electric vehicles has a number of implications, including on the production side. For example, the Chevy Bolt has 80% fewer moving components. Ford has noted that it takes half the capital investment to build an electric vehicle compared to the current gas and hybrid solutions. It also reduces the work hour build time per car by 30%. This, in theory, reduces cost and dependency on workers.

The electric vehicles also have a higher percentage of electronics to cover everything from ADAS to battery management. The artificial-intelligence and machine-learning aspects being incorporated into this type of platform continues to ramp up, addressing details like obstacle recognition to power efficiency of the motor drive.