Ducted fuel injection for diesel engines, developed at Sandia National Lab’s Combustion Research Facility by Charles Mueller, can fine-tune the fuel-air mixture in an engine to the point of eliminating between 50% to 100% of the soot typically generated by diesels. “And engine manufacturers are starting to show excitement about it,” he says. Manufacturers like it because it cleans up the emissions, it work well with conventional diesel fuels, and it is conceptually simple and can be built from low-cost materials.

“Ducted fuel injection could also be retrofitted onto existing engines,” Mueller says. “This is especially important for large engines, such as those used in ships and locomotives where the engines can cost $1 million or more and converting to all-electric power is cost-prohibitive. A retrofit would be relatively inexpensive and could provide substantial emissions benefits right away.”

Mueller got the idea for ducting the fuel injection from a Bunsen burner, which can be found in almost every high school science classroom in the nation.

“If you unscrew the tube on a Bunsen burner and light the gas jet, you get a tall, sooty orange flame,” Mueller says. “But turn off the gas, screw the tube back on, and re-light the burner. Now you get a nice, short blue flame right at the end of the tube. The flame is blue because there isn’t any soot.”

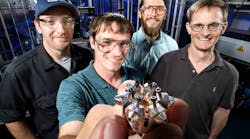

Mueller thought the concept could be adapted to combustion engines, so he gathered a team at Sandia and began experimenting. The researchers now have a prototype consisting of four to six small tubes (or ducts) that direct the fuel-air mixture from the injector to the points of ignition.

Mueller point out that injectors in traditional diesel engines create igniting fuek-air mixtures containing 2 to 10 times more fuel than is needed for complete combustion.

“When you have that much excess fuel at high temperature, it produces a lot of soot,” he says. “Installing the ducts gives us diesel combustion that forms little to no soot because the mixtures contain less excess fuel.”

Generations of diesel engine designs have failed to eliminate soot because there was a physical limit to the chemistry of fuel combustion. “Soot is second only to carbon-dioxide as a chemical that forces climate change, and it’s toxic, so its emissions should be minimized,” Mueller explains. “In the past, there’s always been this problem called the soot-NOx trade-off. So, when we did something to lower soot, emissions of nitrogen oxides—or NOx—go up, and vice-versa.”

Nitrogen oxides are also atmospheric pollutants, and the trade-off meant that truck, car, and equipment makers couldn’t meet current legislated limits without adding exhaust-gas aftertreatment devices. These devices are much like catalytic converters on spark-ignition engines, though significantly larger and more expensive. But with the ducted injection removing almost all the soot, the trade-off game is over.

“So, we can add dilution, routing some of the engine exhaust back to the intake to get rid of NOx without soot emissions becoming a problem,” says Mueller. “It’s like a two-for-one deal on reducing pollutants.”

Mueller said that in engine experiments, his team has observed simultaneous, orders-of-magnitude reductions in soot and nitrogen oxides.

“This gives us a path to much lower emissions for diesel engines, solving a long-standing problem for this highly efficient technology,” he says.

The near-elimination of soot and nitrogen oxides may also open up the market for renewable fuels. “Ducted fuel injection works great with conventional diesel fuel, but it works even better with oxygenated fuels, which have one or more oxygen atoms bonded into some or all of their molecules,” Mueller notes. “Many renewable, sustainable fuels are oxygenated.”

“Using oxygenated fuels with ducted fuel injection lowers emissions, perhaps enough to lower the cost on car and truck engines because less exhaust aftertreatment would be required,” he adds. “On modern trucks, aftertreatment amounts to about $12,000 in initial and operating costs over the life of the vehicle. Reducing even a fraction of those costs is a big deal, given the large number of these vehicles and their importance to the economy.”

Paul Miles, manager of the Sandia’s engine research program, said the potential impact of ducted fuel injection cannot be overstated.

“Breaking the trade-off between soot and nitrogen oxides is a research area of highest priority for diesel engine development,” Miles says. “This is an example of the key role of government supported research—to identify and demonstrate the potential of innovative, high-risk technologies to reshape the landscape for an industry, our transportation infrastructure and our society, and then to work alongside commercial partners to get the technology into the marketplace.”

Ford and a manufacturer of off-road equipment recently signed a Cooperative Research and Development Agreement with Sandia to help advance the technology.