Future-Proof Advanced EVs by Adopting 48-V Zonal Architectures

What you’ll learn:

- The migration to higher voltages in vehicle systems.

- The power and weight advantages in a 48-V system.

- Deploying an automotive zonal power architecture.

The evolution of the automobile has been in a state of disruptive change and growth for a while now, with no signs of letting up. Every aspect of a vehicle, from how it moves to how it interacts with its passengers and other vehicles, is being changed. This not only applies to the vehicle itself, but the social infrastructures around it, from electric-vehicle charging systems to smart-city interactivity.

When it comes to vehicle electrification, switching the power and propelling a vehicle with an electric motor is the easy and straightforward part. But to create next-generation EVs, the design of the whole vehicle must be addressed holistically.

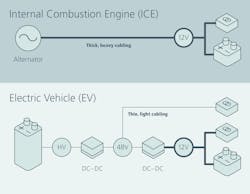

For example, in a legacy fuel-driven car with an internal combustion engine, there was an alternator or generator making the electricity, usually more than the average vehicle needed. These systems typically provided a low 12 or 24 V of power depending on the design.

So, power design engineers working on vehicles had a fairly simple life, knowing roughly how much power they needed and that it didn't limit how far or how fast it could go. Now, suddenly, when it comes to an EV, running the lights or running the radio limits range. This forced car designers into a balancing act, as the power in that battery can either be used to move the car or for something else, losing range.

Why Higher Voltages are Important in Modern EV Systems

A major aspect of modern EVs is that they use higher voltages, often 400 or 800 V. High voltages are a safety hazard, so vehicle designers must be aware of where high voltage is in relation to touch points or where people will be located.

Most EV designs have an in-vehicle working voltage of 12 V. Although 48 V has been a goal of the automotive community for years, the need to create a new alternator design, along with 48-V pumps, compressors, windshield wiper motors, and everything else, delayed development until recently.

Now the industry can start to take advantage of the benefits of 48 V in a vehicle’s power-distribution network. However, vehicle design still comes down to those two magical words for the automotive business: cost and weight (Fig. 1). The benefit in a 48-V system is that the primary cables are smaller and have less copper, meaning that they weigh less and cost less. Another benefit is that these cables are much smaller in diameter, so they're much easier to physically route within the vehicle.

The ability to go to 48 V meshes with a zonal power architecture’s ability to minimize control systems and communication cables by going to three or four zonal controllers, rather than with dozens of chips scattered throughout the vehicle. It also helps address the costs in developing and validating a new 48-V wiper motor or new 48-V front-end lighting system by enabling designers to take the highest loads and first convert those to 48 V.

Implementing a zonal architecture in the power-distribution network enables you to take selected loads and move those to 48 V, but still maintain 12 V at the front and back end of the car and the info stack. Such a hybrid power-distribution system can have a core that’s 48 V, with local conversion to 12 V where needed. This mimics the latest board-level distributed power architectures used in embedded systems.

Voltage-Conversion Strategies for Electric Vehicles

There are several approaches to the challenges of converting HV (800 V or 400 V) to 48 V, and then to 12 V. The standard approach uses many discrete components in a very large layout. A new approach takes miniaturized technology leveraged in the high-power computing business and adapts it for automotive uses to handle all of the charge conversion needs of an automobile.

One of the issues in converting down to 48 V is creating the type of power needed by the end load, be it an unregulated load or regulated load. Another aspect is managing the power from regenerative braking. It’s important to have a bidirectional solution so that when the regenerative braking system is pushing 48 V back up the chain, it can go back into the battery.

This also applies to other advanced subsystems like active suspension and active steering systems that may have regenerative power. They might be drawing 48 V, and they might be inserting 48 V back.

For example, the Vicor BCM bus converters are inherently bidirectional. They can step up or step down the power without having to go through control steps, automatically shifting from bucking to boosting or boosting to bucking. The converters will sense which way the current wants to go and will react to that.

BCMs, which are high-density, high-efficiency, fixed-ratio (non-regulating) isolated DC-DC converter modules, come in a ChiP package or VIA package. That simplifies cooling while offering PMBus control, EMI filtering, and transient protection.

They’re available with inputs from 800 to 48 V, with various K factors to address a range of applications, including automotive. Leveraging the company’s Sine Amplitude Converter topology, high-voltage BCM ChiPs are able to reach peak efficiencies of 98% with power densities up to 147,000W/l3. Easily paralleled into high power arrays with outputs that can be put in series to achieve a higher output voltage, BCMs are inherently bidirectional and enable designers to reduce the bulk capacitance needed at the load.

Therefore, how the system can buck voltage down or boost voltage up and switch inside the vehicle is important, especially when you consider advanced applications like home to vehicle to home, and vehicle to grid to vehicle. A vehicle’s power electronics will have to continue to evolve to address these and other emerging inter-platform functionalities.

Another example can be found in the NBM family of fixed-ratio (non-regulating) non-isolated, bidirectional DC-DC converters. The devices provide a complete DC-DC solution without the need for an external input filter or bulk capacitors. The NBM2317 features built-in hot-swap capability and inrush current limiting, with fast transient response supported by its low output impedance. The NBM family of converters are available in through-hole ChiP and surface-mount SM-ChiP packages.

Power and Weight Advantages in a 48-V System

The weight of the wire harness is a big driver in the migration to a 48-V vehicle, one of a number of technical benefits in moving to 48-V subsystems and motors. Higher-voltage motors are more powerful, more energy-efficient, and allow you to downsize the primary power feeds. The savings are not insignificant, as a vehicle’s wire harness can be made up of hundreds of feet of wire. Thinner and lighter wiring is also easier to integrate into the vehicle and around its subsystems.

In addition to the weight savings on the main power distribution and wiring harness, it improves thermal management because the system is more efficient, emitting fewer watts of heat. Thermal management is important in an EV to keep the batteries cool, which are very finicky when it comes to temperature. Furthermore, other electrical systems have longer operating lifetimes when you manage the temperatures so that you don't have a breakdown within the system and ultimately a failure.

If you save a hundred watts of power through efficiency improvement, that can be a savings of a gram per kilometer of CO2 in an internal combustion engine, or up to 10 km of range in an EV.

Deploying a Zonal Architecture in 48-V EV Power Networks

In the case of a zonal architecture with an 800-V feed, we can do a single conversion to 48 V for the nose-to-tail network. When we get to where the loads are physically located in the vehicle, we can locally make 48 V step down to 12 V. Without having to run wire all the way through the car, you simply could have a front left and right zones. Then you can connect the loads to those. Subsequently, do the same thing at the back of the vehicle with a 48-V primary system and local 12-V loads. This also makes for a more flexible and future-proof design as vehicles migrate to other voltages and power levels.

For example, consider a zonal architecture based on Vicor BCM, DCM, and PRM devices, which are designed to work in an array (Fig. 2). They can talk to each other and perform current sharing so that you don't overload one and underload the other. This makes it easier to design up or design down the power system without having to do a large amount of redesign work.

Such an approach also helps in vehicles where there’s still a small 12-V battery in the system to address functional-safety requirements—the intelligent parts of the vehicle are run to achieve a safe state.

So, between these three devices, the system can take a high-voltage 800-V battery to a 48-V power feed that can be stepped down to a regulated or unregulated 12 V. One of the advantages of the technology is the zero-voltage switching with transients of millions of amps per second.

Thanks to the speed of switching, the system can go from the high-voltage battery to the load as fast as if they were carrying extra batteries at the lower voltages. Manufacturers can do any number of things with the reduced space and weight.

Electrification is going to enable OEMs to convert their vehicles to a 48-V-based power-distribution network, leveraging technology like Vicor’s highly power-dense DC-DC conversion modules to create a 48-V system. A zonal architecture leads to a future-proof design that could be scaled up or scaled down to address current and future power needs.